Retort furnace for gas nitriding process – ZeroFlow®

Modern, energy-saving and ecological gas nitriding process used in HRN/VRN type furnaces

ZeroFlow® is a modern variant of controlled gas nitriding ensuring the maximization of process effectiveness and efficiency as well as economic efficiency, significantly exceeding the results of traditional solutions. It allows for precise shaping of any nitrided layer composition while maintaining minimal media consumption and post-process gas emissions, meeting the most stringent environmental protection regulations.This is especially important for mass production, where the benefits of ZeroFolow® technology will be most significant.

The uniqueness of the ZeroFlow technology lies in the fact that during the nitriding process, when the load does not absorb nitrogen from the atmosphere (e.g. during the reduction of nitrogen potential or in the diffusion phase), the introduction of ammonia into the furnace is completely stopped (zero flow) and the furnace remains tightly closed.

This is a unique feature of the ZeroFlow technology and the horizontal type VR and plunge type PVR and automated process lines based on both previously mentioned types of furnaces dedicated to this technology. It enables the implementation of the most efficient nitriding processes, with minimum duration, energy and gas consumption, and post-process gas emission.

Compared to traditional processes, ZeroFlow reduces the ammonia and nitrogen consumption many times as well as gas emissions to the environment (up to 10 times), and at the same time contributes to energy savings.

It is a technology that protects the natural environment and supports sustainable development.

The ZeroFlow® technology allows to maintain full versatility of conventional gas nitriding while minimizing media consumption, i.e. their significant reduction compared to competing technologies.

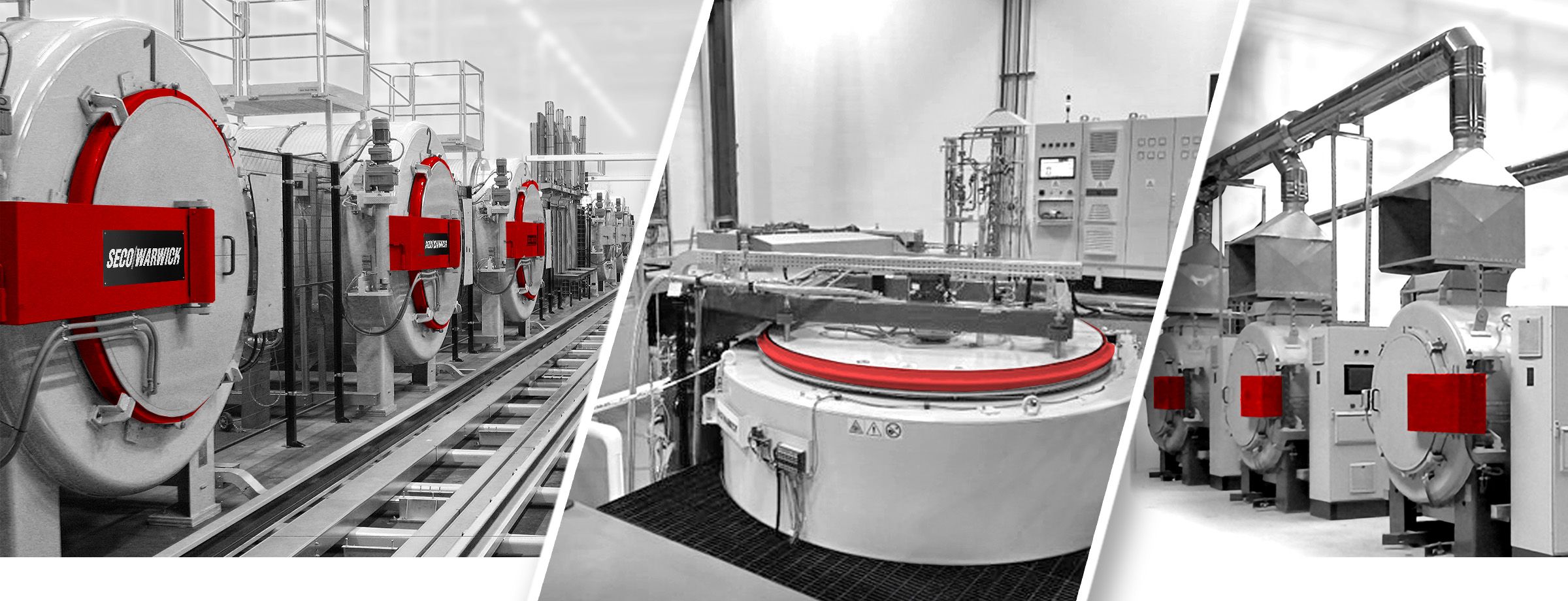

Horizontal type VR and plunge type PVR (including automated process lines) furnaces equipped with ZeroFlow® technology belong to the family of retort nitriding furnaces with horizontal or vertical loading and vacuum purging, available in a wide range of sizes and workspace capacities. These furnaces are compact, equipped with an internal atmosphere mixer and a cooling gas blower to accelerate the load cooling in the retort. The special design of the retort and heating elements ensure the furnace’s long-term and reliable operation in industrial conditions.

In VR and PVR furnaces, the nitriding process is carried out in automatic mode with the possibility of combining individual devices into automated technological lines. The furnace can be equipped with nitrocarburizing (FNC) and post-oxidation installations. In addition, these furnaces can be used for a wide range of tempering and annealing processes, which further increases their versatility.

The advantages of ZeroFlow® nitriding over traditional processes are:

/ Ability to use ammonia alone as the most efficient nitrogen carrier (without dilution with other gases, e.g. nitrogen or dissociated ammonia).

/ Minimal ammonia requirement, just to supply the necessary amount of nitrogen to the treated details in the tightly closed furnace (as opposed to the traditional process where the atmosphere is continuously flowing through the open furnace and only a small amount is used for nitriding).

/ The utilization of the furnace vacuum evacuation (instead of traditional purging with process gases), which significantly reduces the consumption of process gases (ammonia and nitrogen).

/ Precise and dynamic process control by directly measuring and controlling the nitriding atmosphere composition inside the furnace using only ammonia and internal dissociation.

/ It ensures very high accuracy of forming the required nitrided layer.

/ Accurate shaping of any nitrided layer composition

/ Maximum efficiency and process performance

/ High quality and repeatability of results

/ Compliance with the environmental protection regulations requirements

/ Furnace’s reliable operation in an automatic cycle

/ Precise control of the nitriding atmosphere directly in the retort

/ High accuracy of temperature control, uniformity +/-3oC

/ Computer control system based on PLC + IPC Siemens standards

/ Full automation and visualization of the heat treatment process

/ Simple and intuitive furnace operation and process recipe preparation

/ Compliant with AMS-2750, AMS-2759 and CQI-9 standards

/ Data archiving and reporting system

/ Preventive Maintenance function

/ Remote Diagnostics

/ Compact design

/ Automotive industry: e.g. brake discs, gears and pinion shafts, hydraulic pump components, crankshafts and camshafts, sleeves, valve springs, suspension springs, piston rings and pins.

/ Machine industry: e.g. sleeves, pins, shafts, rings, cylinders.

/ Tool industry: e.g. cutting tools, forging dies, dies for extruding aluminum profiles, die inserts, screws of plastic injection molding machines, mold parts for aluminum casting, press moulds, forming fittings, etc.

/ ZeroFlow® gas nitriding process:

-

-

- Nitriding takes place in a tightly closed retort with forced atmosphere circulation.

- The nitriding process is controlled by partial or complete closing of the ammonia inflow to the retort and controlled ammonia dissociation inside the retort.

- During Zeroflow® nitriding, the temperature and nitrogen potential KN are controlled based on the measurement of the hydrogen content in the retort (and not at the furnace gases outlet). The current value of the nitrogen potential (KN) is compared with the set value (according to the recipe) and automatically regulated by the PLC control system by periodically dosing ammonia with a mass valve according to the PID algorithm.

- The atmosphere discharged from the furnace is disposed of in order to meet the requirements of gas emissions to the environment.

-

/ Nitriding

/ Nitrocarburizing (FNC)

/ Post-oxidation

/ Tempering

/ Annealing

/ Others

Green nitriding using the ZeroFlow® method:

/ process control by a nitrogen stream to the part with minimal ammonia consumption,

/ ammonia demand is significantly reduced, up to 10 times less than traditional technology,

/ minimal emission of post-process gases meeting environmental protection requirements,

/ vacuum purging instead of gas purging reduces inert gas utilization,

/ precise building of any nitrided layer configuration, efficient process,

/ nitrocarburizing carried out effectively and efficiently using methanol.

What is the nitriding process?

It is the introduction of nitrogen to a metal or alloy surface (usually steel) in a thermochemical process.

What does the nitriding cause?

It results in the formation of a hardened surface layer with increased mechanical strength and resistance to abrasion and corrosion.

What is nitriding used for?

It is used in the production of cooperating frictionally machine elements, in power transmission systems, e.g. such as: wheels, gear shafts, rings, bushings, bearings, pushers, etc. and for improving the cutting tools and dies surface for plastic forming.

How is steel nitriding different from carburizing due to the process sequence?

Usually, nitriding is preceded by thermal improvement (with hardening), while hardening occurs after carburizing.

How is steel nitriding different from carburizing due to the process temperature?

Nitriding is carried out at temperatures of 450-600 oC, while carburizing is carried out at austenitizing temperatures, usually 800-1100 oC.

Where is carburizing and where is nitriding used?

Carburizing is typically used where thicker hardened layers are required, for heavier loads and more massive parts. Nitriding is used in thinner layers, where abrasion resistance is the key.

What is the difference between nitrided and carburized layers?

The hardened nitrided layer can achieve higher hardness and lower friction, and exhibit better heat resistance and anti-corrosion properties.

DOWNLOAD

Cambridge Heat Treating puts ZeroFlow® Nitriding Process to the Test – See the movie!