It took just four weeks from the moment the order was placed for SECO/WARWICK to deliver one of its most versatile products, the single-chamber Vector vacuum furnace, to the Turkish service hardening plant, More Heat Treatment A.S. This device will not only expand the range of heat treatment services offered but will also serve as a showroom piece for future clients in Turkey. More Heat Treatment has become SECO/WARWICK’s official business partner in the Turkish market.

The SECO/WARWICK Showroom in Turkey

This is the third SECO/WARWICK device delivered to this hardening plant. The new furnace will allow the Turkish Partner to increase its processing capacity while maintaining high precision and quality of treated components. The collaboration between SECO/WARWICK and More Heat Treatment A.S. is strategic—the Turkish company serves as a showroom for potential SECO/WARWICK customers in the region. Prospective partners can witness SECO/WARWICK furnaces in action under real production conditions, further strengthening the Group’s position in the Turkish and Middle Eastern markets.

“Our partner approached us after signing a contract for a very large volume of processed components. Thanks to the very short delivery and production implementation time of the single chamber vacuum furnace, More Heat Treatment will be able to meet this new challenge and immediately ramp up its production and hardening processes. Additionally, we have entered into a long-term cooperation. More Heat Treatment will make our equipment available to potential customers as a demonstration furnace, enabling us to have a stronger presence in this part of the world,” commented Maciej Korecki, Vice President of the Vacuum Segment at SECO/WARWICK Group.

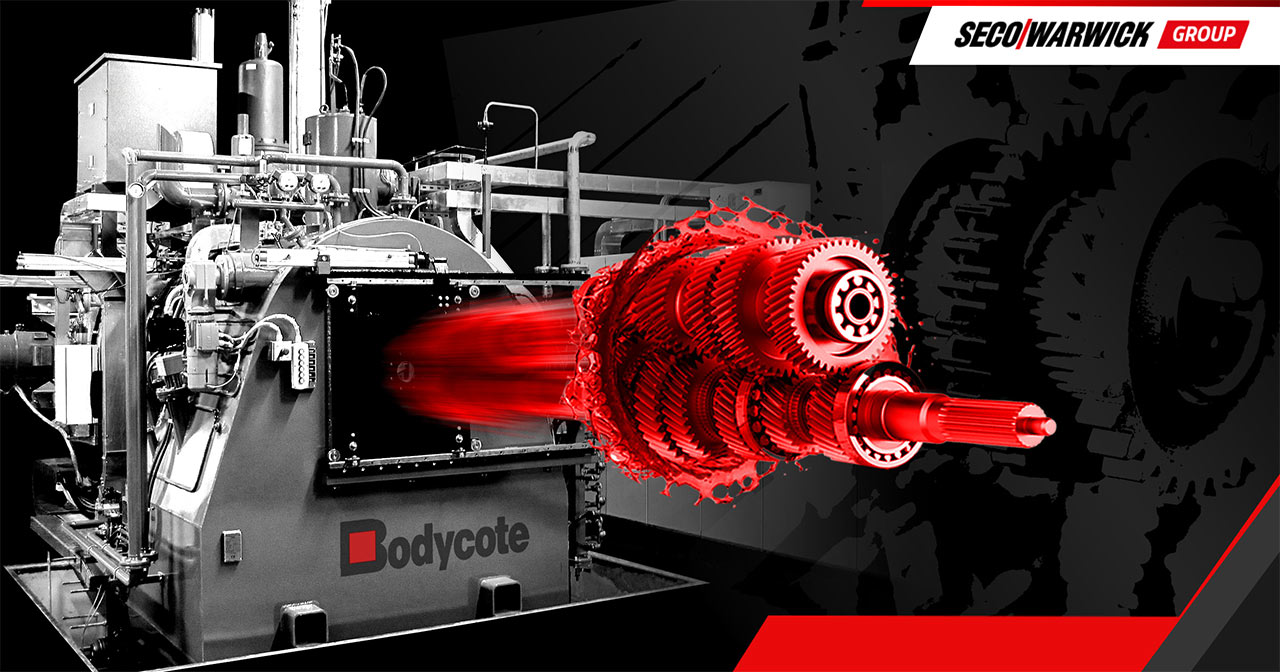

Delivering a Wide Range of Processes and Technologies — Vector is the Answer

Commercial hardening plants are specialists in metal heat treatment and represent a highly demanding group of customers. They face daily challenges in processing a wide array of materials and various processes. The primary limitation for a hardening plant is the available floor space and the efficient use of its machine park while simultaneously offering clients the broadest possible range of services.

The Vector delivered features a spacious working chamber of 600 × 600 × 900 mm, enabling the processing of larger components, and is equipped with numerous options that enhance process efficiency and quality, including convection heating, directional cooling for complex-shaped parts, isothermal hardening, a round heating chamber with uniform temperature distribution (±5°C), a high-performance pumping system (Leybold SV300B + Root’s WH700), partial pressure system and 15 bar abs gas cooling. These solutions ensure process cleanliness, high repeatability, and energy efficiency, which is crucial for demanding industrial applications such as aerospace and automotive.

“We highly value the trust More Heat Treatment A.S. has placed in us. This is the third SECO/WARWICK device delivered to our Partner’s facilities. The fact that our furnaces operate for such a demanding client is the best proof of their quality and reliability. Thanks to close cooperation and swift negotiations, we were able to deliver the furnace in record time—just four weeks after the contract was signed. This demonstrates our flexibility and ability to respond to urgent production needs,” said Łukasz Chwiałkowski, Sales Manager at SECO/WARWICK.

Commercial Hardening Plants—A Demanding Client

SECO/WARWICK supplies equipment to all the leading players in the commercial hardening segment. As a manufacturer of metal heat treatment equipment, the company has in-depth knowledge of the specifics of hardening plant operations and understands which parameters matter most to these Partners. More Heat Treatment is a Turkish heat treatment center offering a wide range of additional services. From the very beginning, More Heat Treatment has aimed to support clients with an extensive array of processes—from material selection to final component finishing. Thanks to this approach, the company has become a pioneer in the industry—currently serving over 100 factories both in Turkey and internationally.

“SECO/WARWICK is a proven technology partner. We have previously used their furnaces, which operate reliably in our hardening plant. The new furnace enables us to increase our production capacity and quickly meet new contracts. Working with SECO/WARWICK gives us confidence in quality, technical support, and innovation. We are also pleased with the prospect of broader cooperation, as SECO/WARWICK equipment deserves greater exposure in the Turkish market,” commented Sakine Ülker, Managing Director from More Heat Treatment A.S.