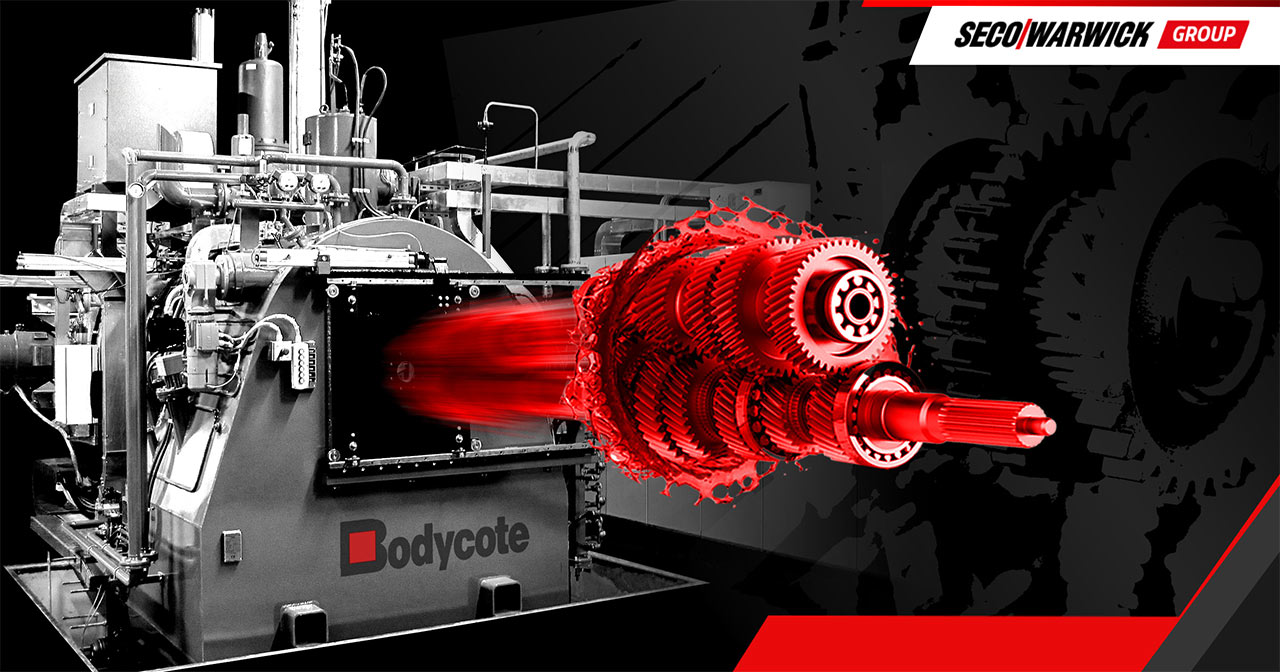

Bodycote Polska Sp. z o.o., a part of the global Bodycote Group - the world's leading provider of heat treatment services - has purchased a CaseMaster Evolution vacuum furnace from SECO/WARWICK. This investment is another step in the development of the Bodycote branch in Siechnice to increase the efficiency and technological capabilities of the plant.

Vacuum carburizing in commercial hardening plants

The new device is a dual-chamber vacuum furnace (CMe-D) equipped with an oil quenching system and an advanced FineCarb vacuum carburizing system. Thanks to this technology, the Bodycote plant in Siechnice will expand its range of services, including heat treatment processes such as vacuum carburizing — processes that were previously beyond their technological reach.

«CaseMaster Evolution (CMe) furnaces are well-suited for many processes, which is why they are perfect for places like commercial hardening shops. These multi-chamber furnaces combine heat treatment in a vacuum with traditional oil quenching in dual- or triple-chamber configurations, enabling high efficiency, and delivering clean, oxide-free (IGO) parts. The Bodycote Group is a key partner for us, thanks to our shared commitment to advanced heat treatment technology. We are pleased to help expand the portfolio of services for the Polish branch,» said Maciej Korecki, Vice President of the Vacuum Segment Group at SECO/WARWICK.

The features of the design on order includes an oil quenching system ensuring fast and uniform cooling of the charge, as well as the FineCarb vacuum carburizing system, which allows for precise control of process results.

«The FineCarb vacuum carburizing technology enables the implementation of advanced thermochemical processes. Thanks to the furnace’s modern design, the Siechnice plant will increase its quality, efficiency, and process economy. Using the latest technological solutions also contributes to improving ecology and reducing operating costs, which is particularly important in the face of rising energy prices,» commented Jędrzej Malinowski, Sales Manager at SECO/WARWICK.

The SECO/WARWICK partnership with a global hardening plant

Bodycote Siechnice has been using SECO/WARWICK solutions for years, and the new vacuum furnace is the 12th SECO/WARWICK device in the plant, although the first from the range of vacuum furnaces.

«The dual-chamber CaseMaster Evolution (CMe-D) furnace is another step in expanding our LPC technology capabilities. We have several years of experience in vacuum carburizing, and we see that our customers are currently more interested in this process. This was the correct choice to meet the requirements for implementing sustainable development strategies and reducing CO₂ emissions. The new furnace will allow us to conduct cleaner carburizing processes without an endothermic atmosphere. We believe that we will improve the efficiency of our processes with this furnace, which will positively affect the economic aspect. This fits into our strategy as Bodycote constantly strives for innovation and operational excellence, developing its global and local competencies. Investing in modern vacuum equipment from SECO/WARWICK strengthens our company’s position as a trusted partner for the industry, offering the highest quality heat treatment services,» said Dariusz Podgórski, Vice President of Bodycote Polska Sp. z o.o.

SECO/WARWICK is an expert in vacuum carburizing. The FineCarb vacuum carburizing process produces both a high repeatability of results, and uniform carbon layers from 0.1 to 5 mm. This technology eliminates internal oxidation and process by-products such as soot and tar, ensuring very high process cleanliness.