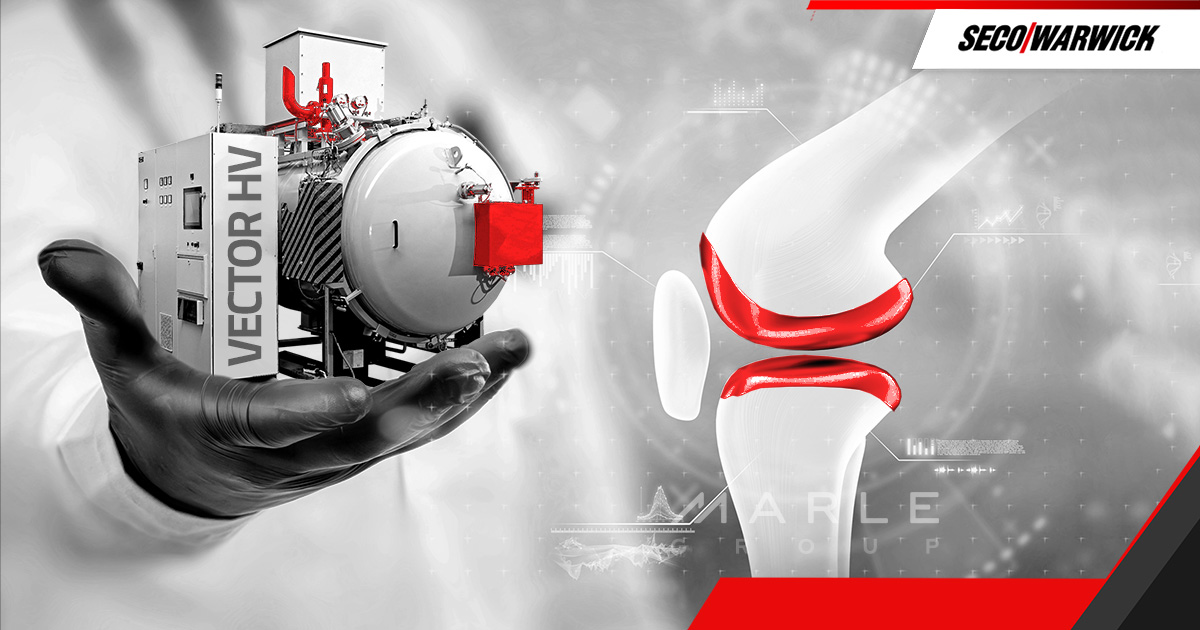

SECO/WARWICK will supply a Vector vacuum furnace to the Marle Group, a global manufacturer of orthopedic prosthetics headquartered in Europe. The equipment will be installed in France at Marle Nowak’s facility, which specializes in the production of orthopedic implants, surgical instruments, spinal devices, and OEM manufacturing for the medical sector. The single-chamber furnace will be used for heat treating implants and surgical tools. The contract was secured thanks to successful reference trials conducted at SECO/WARWICK’s R&D department.

SECO/WARWICK Delivers the Fastest Cooling Solution

Marle Nowak faced a technological challenge—the need for rapid cooling of large implant loads. They required equipment capable of cooling a full load (800 kg) from 1200°C down to 400°C in a very short time. After completing a reference trial in the R&D division with a full load, SECO/WARWICK achieved the best rapid cooling results.

Following successful laboratory trials at SECO/WARWICK, the client decided to purchase the device that delivered the best performance among competing solutions. The SECO/WARWICK vacuum furnace will not only increase production independence but also facilitate the certification of heat treatment processes in line with ISO 9001 and ISO 13485 standards—crucial requirements in the medical industry.

“Hardening cobalt alloys requires processes that achieve extremely high temperatures, and the heating processes for these materials demand high purity, temperature uniformity, and very fast, efficient cooling. The Vector vacuum furnace meets these criteria, guaranteeing the highest quality of treated components. This is the third SECO/WARWICK device operating at the facilities of the European leader in medical manufacturing. Our equipment will allow our partner to become independent from external hardening services, providing greater control over the entire production process,” said Maciej Korecki, Vice President of the Vacuum Furnace Segment at SECO/WARWICK Group.

Marle Nowak: Precision Investment Casting for Multiple Sectors

Marle Nowak specializes in precision investment casting using the lost-wax method, including advanced steel alloys, stainless steel and superalloys for a wide range of industries: industrial (valves, pumps), construction, safety, urban equipment, accessories, and increasingly, the medical sector (orthopedic implants).

A Vacuum Furnace Designed for the Medical Industry

Thanks to a spacious 600x600x900 mm working area and a round heating chamber, the SECO/WARWICK vacuum furnace enables the processing of oversized components. Key features of this design include convection heating for improved heat transfer efficiency at lower temperatures; directional cooling to effectively treat challenging shapes; and isothermal hardening, allowing for enhanced control of the cooling process through better temperature management and frequency-controlled blower operation.

The partial pressure system using argon helps prevent the evaporation and sublimation of alloying elements from the load surface during vacuum heat treatment.

The equipment is fitted with a dew point sensor for both argon and nitrogen gases—an innovation that addresses a critical aspect of heat treatment by preventing condensation of water vapor, a process that can cause oxidation of the treated load surface. Also essential is the high-performance rapid cooling system, based on a blower providing a maximum quenching pressure of 15 bar abs.

“Previously, we relied on commercial external hardening services. Purchasing our own vacuum furnace allows us to establish an in-house, small-scale hardening shop. This, in turn, is aimed at improving the quality and longevity of implants while reducing process time and costs (such as transportation expenses). The ability to conduct tests before purchase was a significant advantage offered by SECO/WARWICK,” commented Stéphane Ghini, Directeur Technologie et Procédés de Fabrication from Marle Group.

R&D Directly Supports the Purchasing Process

Purchasing metal heat treatment equipment for manufacturing plants is an important and responsible decision. Choosing a specific manufacturer and model involves numerous parameters. The key value in a successful purchasing process is the ability to test equipment under laboratory conditions. SECO/WARWICK operates two dynamic R&D centers, enabling trials and process experiments.

“In this contract, it turned out to be the decisive factor. After conducting a reference trial with a full 800 kg load, our partner had no doubts that the SECO/WARWICK vacuum furnace was the best choice. We can tailor our devices to the client’s specific needs, making equipment selection not a compromise, but a real answer to demand. This is SECO/WARWICK’s huge advantage,” stated Łukasz Chwiałkowski, Sales Manager, SECO/WARWICK.

The Medical Industry and Metal Heat Treatment

The role of advanced heat treatment technologies in the production of medical devices—where the highest precision, purity and process repeatability are required—is steadily growing. A vacuum furnace enables the ideal mechanical and surface properties of cobalt alloys, which translates into the durability and biocompatibility of implants. For patients and hospitals, this means higher quality, greater safety and longer product life. Manufacturers of sensitive medical products are increasingly adopting solutions previously used mainly in the aerospace or defense industries. This demonstrates the technological convergence of different sectors and confirms that precise heat treatment is becoming a key stage in the manufacturing of modern biomedical products.