SECO/WARWICK has signed a contract to deliver a state-of-the-art vacuum furnace to a client in the European defense sector. The partner has chosen a proven single-chamber vacuum furnace.

The equipment has been customized to maximize its versatility and provide a broad range of applications for the heat treatment of steels used in the firearm manufacturing industry. In the coming years, Europe is expected to be one of the world’s key markets for investments in armaments and military modernization.

SECO/WARWICK has experience collaborating with the defense sector. Every new contract in this segment offers opportunities for in-depth technical consultations and engineering challenges, which contribute to the development of the company’s portfolio and know-how. Thanks to this approach, SECO/WARWICK has developed a furnace configuration that meets the needs of modern manufacturing plants focused on efficiency, reliability, and flexibility in technological processes.

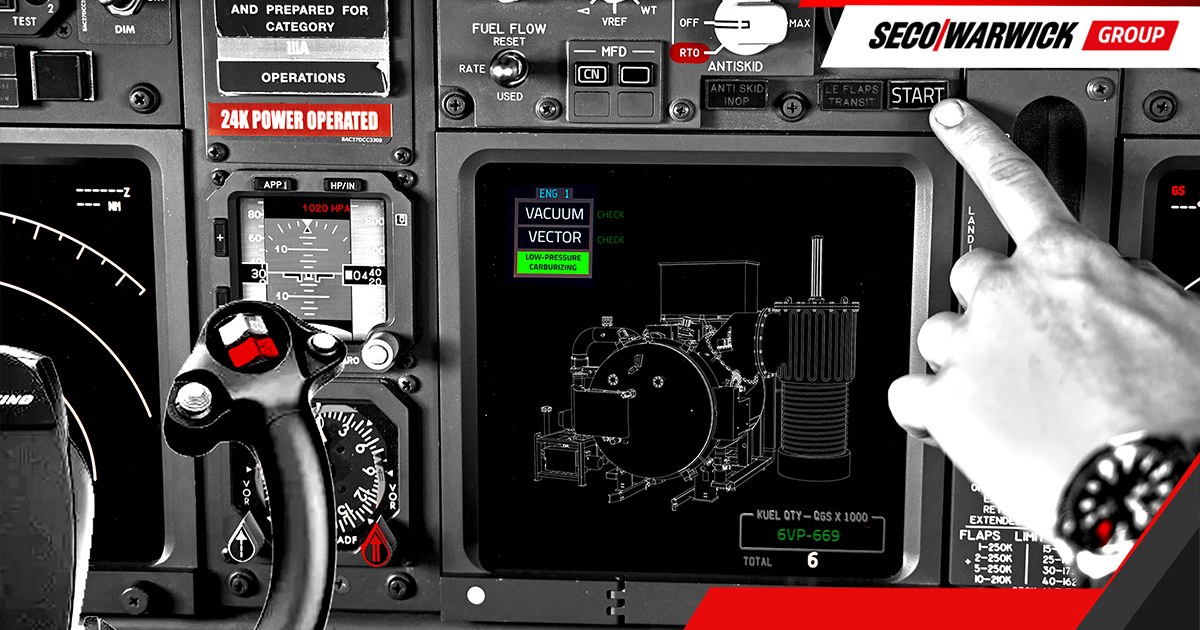

The selection of the SECO/WARWICK solution resulted from a tender procedure announced by the partner. This is the first order carried out by SECO/WARWICK for this client, but it aligns with the broader context of technological transformation in the European defense industry. The transition from gas carburizing technology to modern LPC processes allows the client to significantly improve the quality and predictability of heat treatment, while also optimizing energy and process gas consumption.

“Vacuum technology in the defense industry is becoming not only a response to the need for modernizing production lines, but also a tool for building technological advantage. Firearm manufacturing requires absolute repeatability and quality in heat treatment. Our equipment meets these demands thanks to precision engineering and advanced process technology. This is an investment in safety and reliability that brings tangible benefits from the very first production cycle,” says Maciej Korecki, Vice President of the Vacuum Segment at SECO/WARWICK.

The contract holds strategic and technological significance—both for the client, who is modernizing their infrastructure, and for SECO/WARWICK, which is strengthening its position as a key solutions provider for the defense sector.

“We deliver not only equipment, but above all, the experience and knowledge of how to support industries with the highest standards. Thanks to flexible configuration, our solution perfectly addresses the needs of such clients. The applied solution combines a classic, round heating chamber—enabling the processing of oversized components—with advanced low-pressure carburizing (LPC) technology and a high-pressure gas quenching (HPGQ) system. The equipment stands out due to high temperature uniformity throughout the working space, a convection heating system that increases efficiency at lower temperatures, and directional cooling that allows precise process adjustment to the geometry of complex parts. The graphite chamber is wear-resistant and easy to service, making it a practical choice for multi-shift hardening plants,” explains Łukasz Chwiałkowski, SECO/WARWICK Sales Manager.

Europe increases defense spending

In recent years, defense spending in Europe has reached record levels, reflecting the growing importance of military modernization and strengthening industrial capabilities in the context of a dynamic geopolitical situation. In 2024, total defense expenditures by European countries exceeded € 340 billion, with forecasts indicating further growth in the coming years. More and more countries are surpassing the 2% of GDP threshold for defense spending—a benchmark for fulfilling NATO commitments. A significant portion of these budgets are allocated to investments in modern weapons systems, advanced manufacturing technologies, digital solutions, and research and development. Special attention is given to modernizing industrial infrastructure related to the production of weapons, ammunition, fire control systems, and components critical for modern combat platforms. Europe is also investing heavily in developing industrial capabilities that enhance the region’s technological and military sovereignty and independence. The increase in spending is driving demand for high-quality, reliable, and repeatable processes, which directly contribute to the development of advanced heat treatment technologies used in the defense industry. Observed trends suggest that in the coming years, Europe will continue to be one of the world’s key investment markets for armaments and military modernization.