Production in the aviation industry is accelerating. The year 2024 was record-breaking for aviation. Therefore, it is not surprising that the largest manufacturers of aircraft parts are investing in devices that increase production efficiency. CPP has been a long-term partner of the SECO/WARWICK Group, having placed numerous orders for metal heat treatment equipment over the years.

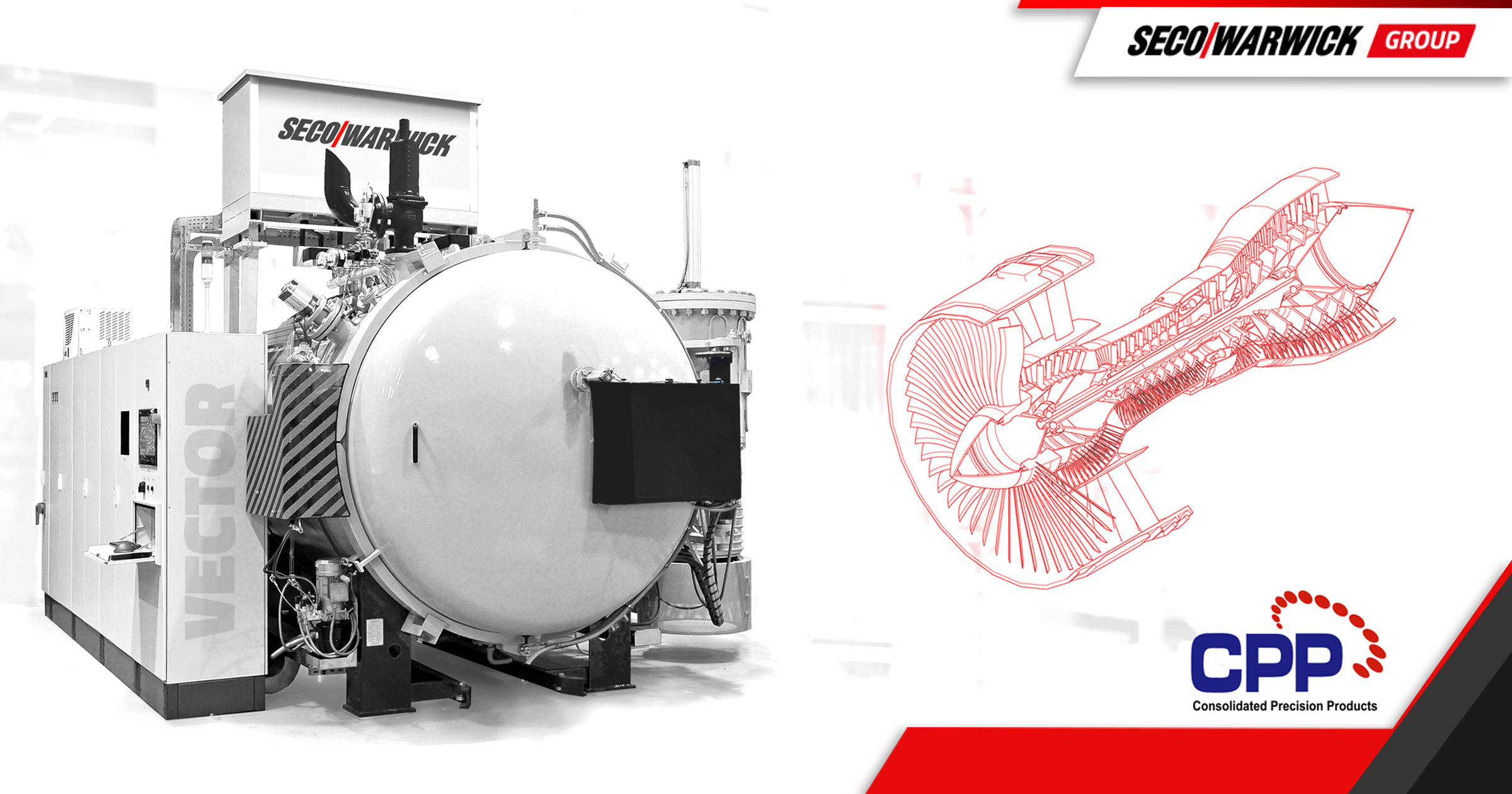

Consolidated Precision Products, an international producer of aircraft parts with two production plants in Poland, has purchased their seventh furnace from SECO/WARWICK Group.

Aviation is booming. Last year was record-breaking in terms of operating profits, but also the number of available flights. This leads to increased efficiency and production in the aircraft industry, resulting in growing investment expenditures. To meet this demand, Consolidated Precision Products purchased an additional SECO/WARWICK vacuum furnace.

“A long-term partner with branches in the USA, Mexico, Belgium, Slovakia and Poland has once again chosen our solution. This will be a furnace for annealing blades cast from single crystals. The unique feature of this furnace is the modifications enabling very clean annealing processes for single-crystal castings. We have implemented a vacuum furnace equipped with a molybdenum heating chamber, partial pressure system, dew point sensors, and a highly efficient high vacuum system. As one of the largest global manufacturers of vacuum devices for metal heat treatment, we significantly feel the revival in the aviation market. Subsequent contracts with this industry confirm the competencies that the SECO/WARWICK Group has been acquiring for decades,” said Maciej Korecki, Vice President of the Vacuum Segment of SECO/WARWICK Group.

Single-crystal blades

CPP has purchased a vacuum furnace with 1.5 bar abs. gas cooling and a molybdenum chamber. This solution is based on the standard design of a vacuum furnace with a working space of 900x900x1200 mm, screen insulation, and metal heating elements that perfectly fits the characteristics and needs of this manufacturer of cast blades.

“The round heating chamber allows for the placement of oversized elements. The furnace has been expanded and modified with dedicated options to meet very high requirements: high vacuum, temperature distribution, operation at high temperatures around 1300 degrees, and cleanliness of processes. The device will be used for annealing blades cast from single crystals. Its advantage is the molybdenum heating chamber, which prevents direct heat loss to the wall of the vacuum chamber and ensures very high process cleanliness. The efficiency of the processes carried out is also influenced by the ability to cool in 1.5 bars of Argon. Thanks to inverter control, we can regulate the cooling speed in the appropriate process segment,” said Paweł Okińczyc, Sales Engineer at the Vacuum Plant of SECO/WARWICK.

Aviation requires quality and precision

This is another SECO/WARWICK device that goes to manufacturers of complex jet engine parts. It is a very demanding group of partners under enormous pressure to produce products of the highest quality and reliability, as they operate in harsh conditions where safety and reliability are priceless.

Consolidated Precision Products specializes in the production of highly precise, geometrically complex systems, parts, and components for the aviation industry. CPP has a global network of production plants in the United States, Mexico and Europe.

“This is not our first collaboration with the SECO/WARWICK Group. Their equipment has been working in our plants for many years. This particular vacuum furnace will be used for the production of a new line of jet engine blades from single crystals. The turbine elements used in the aviation industry operate under high mechanical loads at temperatures close to their melting point and in an aggressive corrosive environment. Therefore, we cannot afford structural defects that would affect the quality or durability of our products. The SECO/WARWICK vacuum furnace will provide us with very high-quality processed elements, but it will also increase efficiency,” explained Dariusz Szawara, Foundry Director of DS/SX at Consolidated Precision Products.

Consolidated Precision Products Poland has a precision production plant in Rzeszów with two departments that supply parts for aircraft engines using the latest technologies for the world’s largest aircraft engine manufacturers. The strength of the company lies in high quality standards, knowledge, and experience, enabling them to adapt to changing needs, and effectively respond to customer requirements. CPP Poland is also a member of the Aviation Valley.