/Heat Treatment for the Aerospace Industry

Heat Treatment for the Aviation Industry

Aviation applications

We cooperate with almost all the major players in the aviation sector. One could say that SECO/WARWICK has its modest share in the vast majority of passenger aircraft production. For this industry, we provide solutions for the manufacture of plane engine blades, heat exchangers, turbine blades, aluminum coatings, landing gears, and brakes, fasteners and other critical components.

/ Vacuum furnaces for the aerospace industry

PARTS: gears, jet engine elements, landing gears, fuel installation.

TECHNOLOGY: annealing, brazing, sintering, forging, hardening HPGQ, hardening OilQ, tempering, vacuum carburizing, CVD, nitriding.

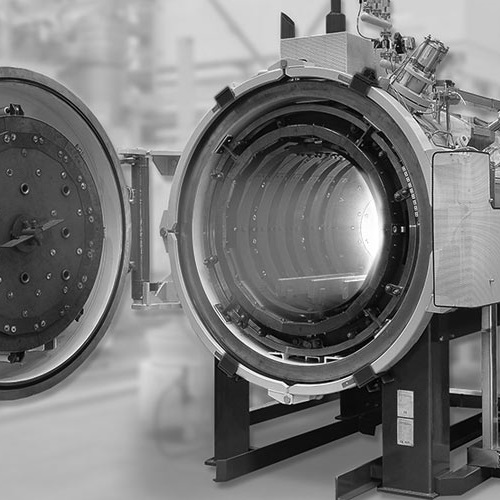

Vacuum furnace with HPGQ – Vector®

PARTS: gears

TECHNOLOGY: annealing, sintering, tempering, brazing, hardening, low pressure carburizing & nitriding (LPC & LPN), solution heat treating

Vector High Vacuum Furnace

TECHNOLOGY: brazing, annealing, normalizing, homogenizing, stress relief, solution heat treating, aging, quenching, diffusion bonding, outgassing, sintering, tempering

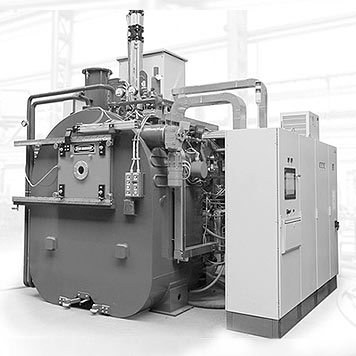

Sealed quench vacuum furnaces for low pressure carburizing – CaseMaster Evolution®

PARTS: fuel installation

TECHNOLOGY: hardening with oil quench or gas quench, low pressure carburizing using FineCarb® with oil or gas quench, high-temperature carburizing up to 1050°C using PreNitLPC® for common case hardening steels, carbonitriding, bright thorough hardening, oxidation in the pre-heating chamber, annealing (with gas cooling), tempering, quenching, brazing

Triple chamber vacuum furnace for low pressure carburizing – CaseMaster Evolution® T

PARTS: heat exchanger

TECHNOLOGY: case hardening LPC, quenching, brazing, annealing

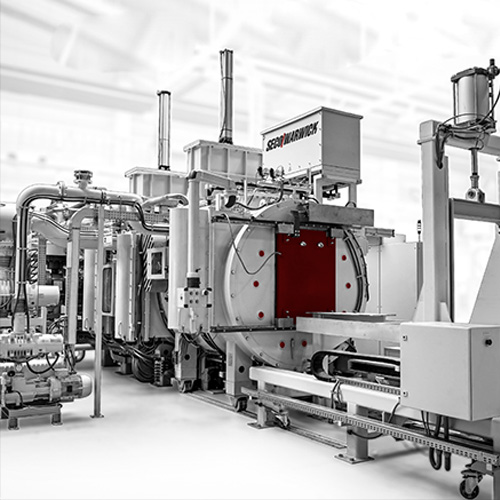

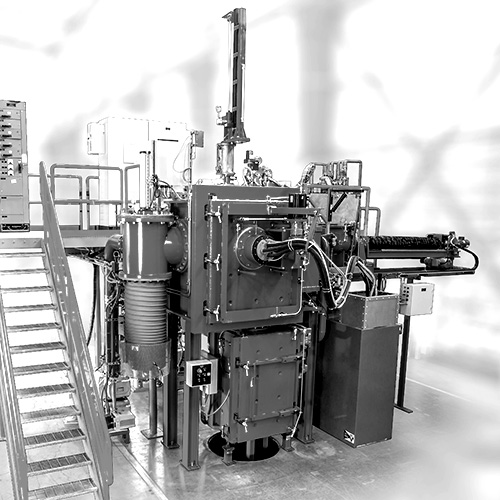

The custom vacuum system for low pressure carburizing – UniCase Master® Custom

PARTS: hydraulic parts

TECHNOLOGY: low pressure carburizing, bright hardening (High Pressure Gas Quench), bright annealing, vacuum brazing

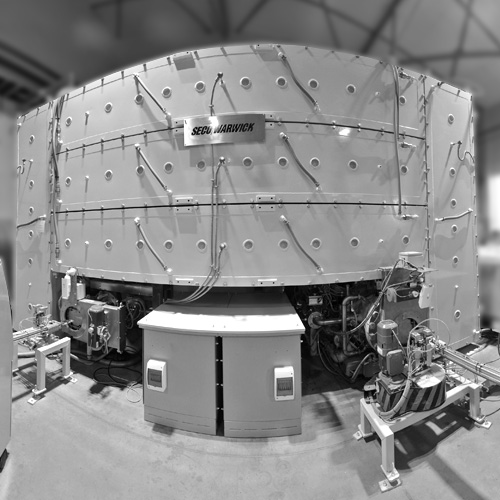

/ Vacuum melting furnaces for the aerospace industry

PARTS: equiax casting, directional solidification, single crystal casting

TECHNOLOGY: turbine blades for jet engine

Vacuum Induction Melting (VIM)

PARTS: turbine blades for jet engine

TECHNOLOGY: equiax casting, directional solidification, single crystal casting

/ Aluminum furnaces for the aerospace industry

PARTS: sheet, castings, tubes and extrusions, castings, aluminum plate, aluminum forgings, aluminum extrusions, aircraft applications and billet preheating

TECHNOLOGY: solution HT, aging, annealing, stress relieving, controlled cooling, controlled heating, aging, annealing, aluminum brazing

Drop Bottom Furnaces for Aluminum - VertiQuench®

PARTS: sheet, castings, tubes and extrusions

TECHNOLOGY: solution HT, aging, annealing, stress relieving, controlled cooling, controlled heating

Aluminum Aging and Annealing Furnaces

PARTS: wire, profile and foil

TECHNOLOGY: aging, annealing

Continuous Aluminum Solution Heat Treatment and Aging

PARTS: castings, aluminum plate, aluminum forgings, aluminum extrusions, aircraft applications and billet preheating

TECHNOLOGY: solution HT, aging