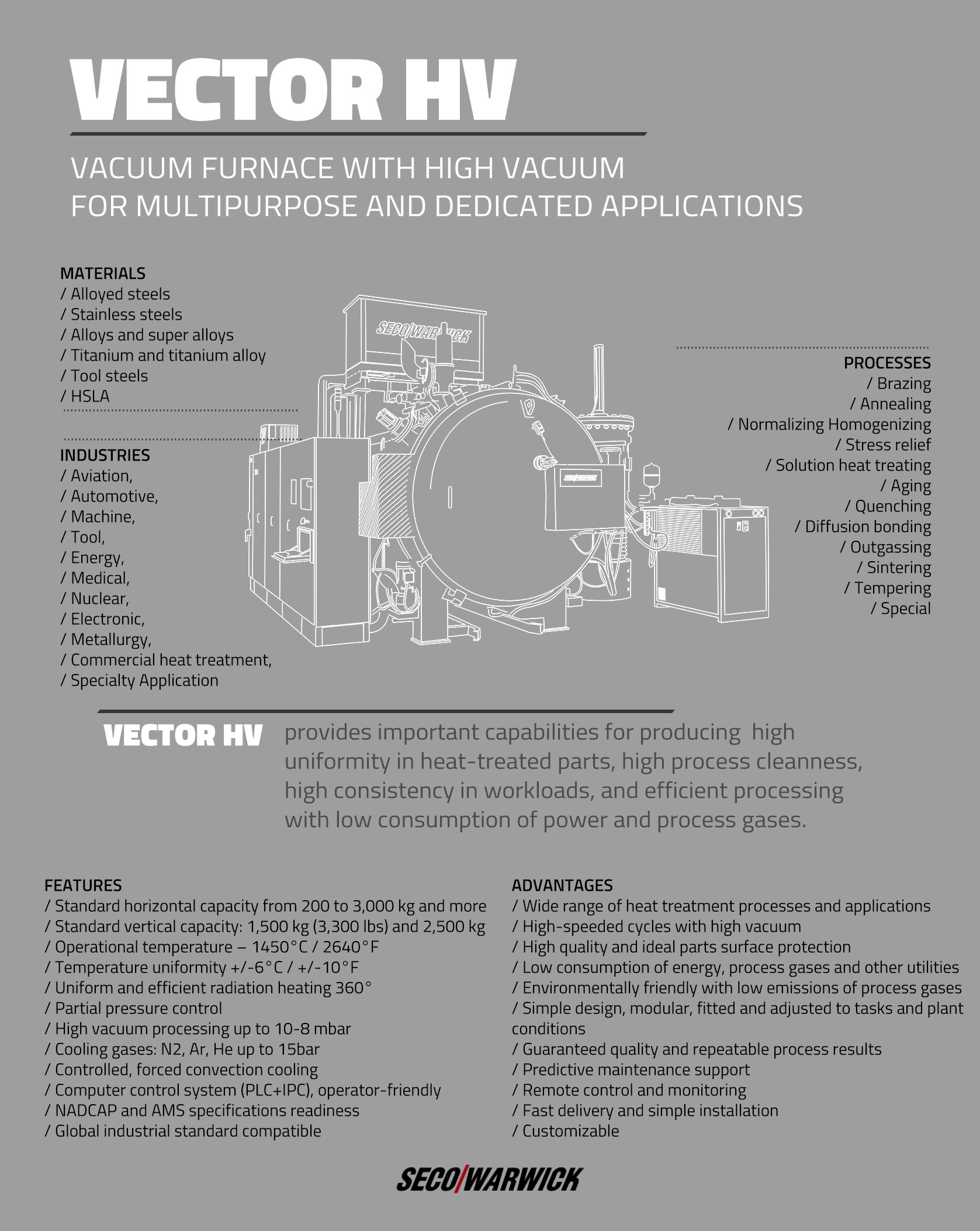

Vacuum Furnace with High Vacuum for multipurpose and dedicated applications – Vector HV

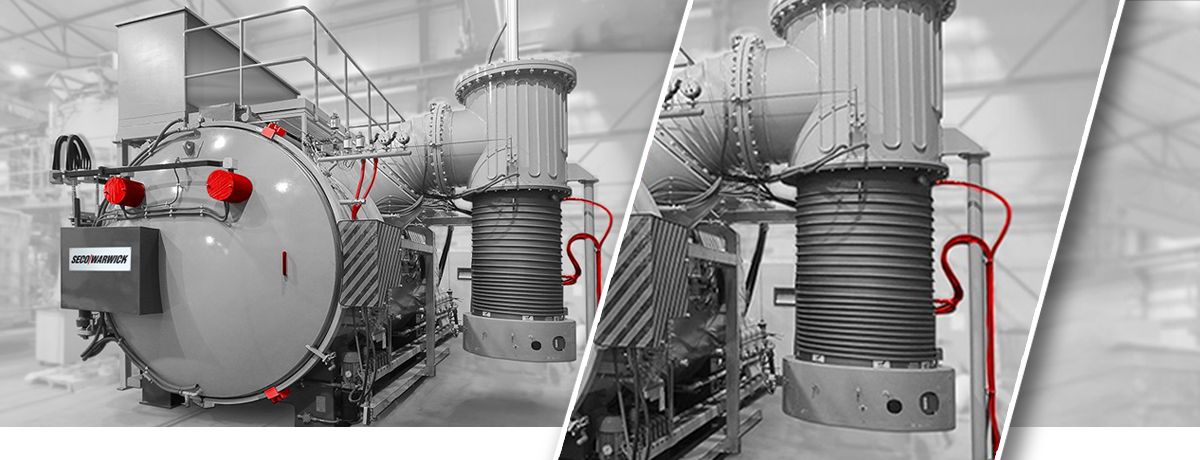

Vector HV is a horizontally or vertically oriented single-chamber high vacuum furnace using gas cooling which can be used for a wide variety of heat-treating processes and applications. It provides important capabilities for producing high uniformity in heat-treated parts, high process cleanness, high consistency in workloads, and efficient processing with low consumption of power and process gases.

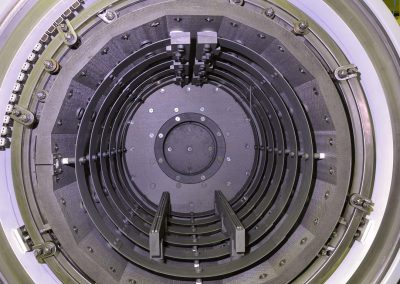

Vector HV furnaces are equipped with round graphite or metal heating chamber. They are the ideal solution for highly demanding heat treatment in terms of high process purity and part surface quality. With hundreds of systems installed worldwide, SECO/WARWICK’s high vacuum furnaces have a proven record of high-performance technology.

The Vector is a single-chamber horizontal vacuum furnace that complies with industrial standards related to heat treatment equipment and has sold many hundreds of units worldwide. It comes with a full range of options and accessories for performing a wide range of functions for heat treaters and can be customized for special functions.

Features

/ Standard horizontal capacity from 200 to 3,000 kg and more (440 to 6,600 lbs)

/ Standard vertical capacity: 1,500 kg (3,300 lbs) and 2,500 kg (5,500 lbs)

/ Operational temperature – 1450°C / 2640°F

/ Temperature uniformity +/-6°C / +/-10°F

/ Uniform and efficient radiation heating 360°

/ Partial pressure control

/ High vacuum processing up to 10-8 mbar

/ Cooling gases: N2, Ar, He up to 15bar

/ Controlled, forced convection cooling

/ Computer control system (PLC+IPC), operator-friendly

/ NADCAP and AMS specifications readiness

/ Global industrial standard compatible

SecoVac Automatic Furnace Control System

Maintenance and Control Features

/ Functional, simple to use, intuitive system

/ Uninterruptible Power System (UPS)

/ Full visualization and comprehensive management of emergency situations

/ Automatic generation of predefined reports (graphic or numeric) and with export to external files

/ Hierarchy of user-access levels

/ Remote control and monitoring

/ Custom setup of all data analysis charts and printouts

/ Full integration with SCADA software – no need of extra software

Production Features

/ Friendly programming of the furnace system processes

/ Advanced process management with an unlimited number of recipes

/System safeguards against wrong technological program selections

Operation Features

/ Operation time counters, ability to plan periodic reviews

/ Multiple languages

/ Viability monitoring of the thermocouples

/ Stored history of equipment operation

/ Media consumption monitoring, with optional refill warnings

/ Two-stage warning alarm – color coding allows immediate identification of alerts

/ Easy system backups

Management Features

/ Integration with higher-level management systems

/ Data security with different levels of user’s access

/ Optimization of production on the basis of stored information

/ Reduced operator workload by automation of the production

/ Programmable for a time/date delay to begin processing with an option for GSM (Global System for Mobile communication) notification

/ Long-term data logging and remote access to archived information

/ Application browser provides “read – only” access to data

Dedicated Auxiliary Equipment

/ Manual and/or automatic loaders

/ Cast metal and/or carbon composite fixtures

/ Closed loop water cooling system

/ Gas buffer tank

/ Helium recycling system

/ Noise protection of the pumping system

/ Inlet gas dew point measuring system

/ Separated water chiller for diffusion pump cooling

/ Temperature uniformity frame

/ Time-saving spare parts set

/ Wide range of heat treatment processes and applications

/ High-speeded cycles with high vacuum

/ High quality and ideal parts surface protection

/ Low consumption of energy, process gases and other utilities

/ Environmentally friendly with low emissions of process gases

/ Simple design, modular, fitted and adjusted to tasks and plant conditions

/ Guaranteed quality and repeatable process results

/ Predictive maintenance support

/ Remote control and monitoring

/ Fast delivery and simple installation

/ Customizable

/ Brazing

/ Annealing

/ Normalizing Homogenizing

/ Stress relief

/ Solution heat treating

/ Aging

/ Quenching

/ Diffusion bonding

/ Outgassing

/ Sintering

/ Tempering

/ Special

/ Aviation,

/ Automotive,

/ Machine,

/ Tool,

/ Energy,

/ Medical,

/ Nuclear,

/ Electronic,

/ Metallurgy,

/ Commercial heat treatment,

/ Specialty Application

/ Alloyed steels

/ Stainless steels

/ Alloys and super alloys

/ Titanium and titanium alloy

/ Tool steels

/ HSLA

Furnace Options

/ Horizontal or vertical orientation

/ Graphite or metal, cylindrical heating zone

/ High vacuum by diffusion, cryogenic, or turbomolecular pumps

/ Higher temperature operation

/ Improved temperature uniformity to class 1 (AMS2750)

/ Multi-zone temperature control

/ Convection heating

/ Low and cryogenic-temperature trap

/ Color selection

Control System Options

/ Selection of PLC and IPC control system

/ Power management control system

/ Independent data recording

/ Remote control and monitoring

/ Air-conditioned control cabinet

Optional Processes

/ Isothermal and controlled cooling

/ Tempering

/ vacuum as a protective and technological atmosphere eliminates the need to use harmful process gases and their emission to the environment,

/ no CO₂ emissions, no use of fossil fuels,

/ gas utilization for cooling (nitrogen, argon), captured and returned to the air, neutral for the environment,

/ reinforced thermal insulation saves electricity (approx. 20%),

/ high energy efficiency of used electrical components (IE3 class motors, inverter control, etc.),

/ application of systems and algorithms limiting energy and technological factor consumption (pumping, heating and cooling systems),

/ no harmful substance emissions,

/ reduction of hardening deformations and downstream machining costs,

/ elimination of part washing after heat treatment.