Vacuum furnace with high pressure gas quenching – Vector®

Vector is a single-chamber vacuum furnace using gas quench which can be used for wide variety of heat treating processes and applications. It provides important capabilities for producing high-uniformity in heat treated parts, high consistency in workloads, and high speeds in batch processing with low consumption of power and process gases.

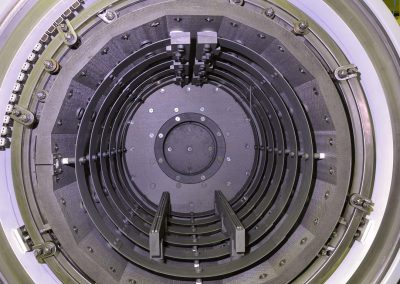

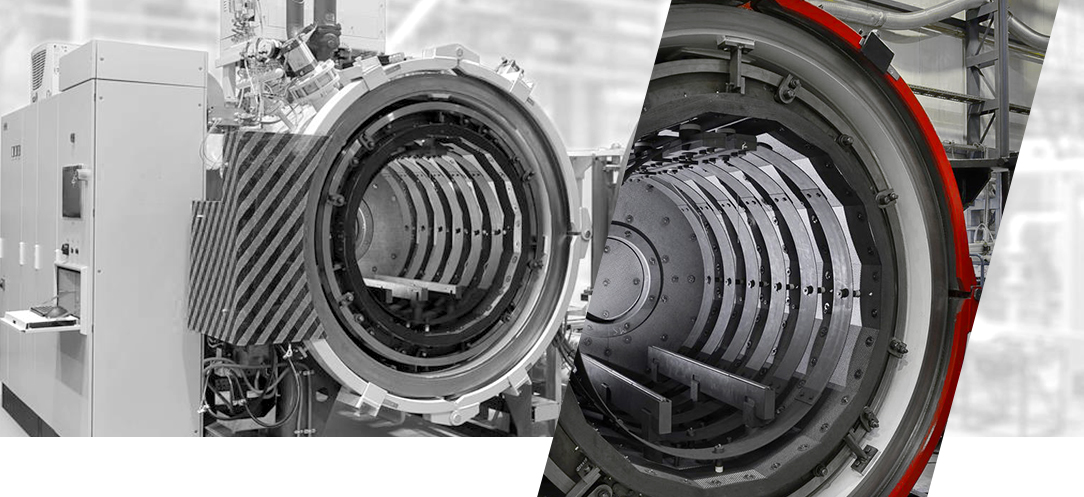

Vector high pressure gas quench furnaces are the ideal solution for heat treating. Vector is a vacuum furnace with round graphite hot zone. These furnaces can be used for most standard hardening, tempering, annealing, solution heat treating, brazing and sintering. Additionally, they can be used with SECO/WARWICK’s optional patented vacuum-carburizing technologies (FineCarb®) and prenitriding (PreNit®) and the SimVac® process simulation package is included at no extra charge. With hundreds of systems installed worldwide, SECO/WARWICK’s high pressure quench furnaces have proven record of high performance technology.

The Vector is a single chamber horizontal vacuum furnace that complies industrial standards related to heat treatment equipment and has sold many hundreds of units worldwide. It comes with a full range of options and accessories for performing a wide range of functions for heat treaters and can be customized for special functions.

/ Standard horizontal capacity from 200 to 2,500 kg and more (440 to 5,500 lbs)

/ Standard vertical capacity: 1,500 kg (3,300 lbs) and 2,000 kg (4,400 lbs)

/ Graphite or metal hot zone with a maximum vacuum of 10-2 to 10-5/10-6 mbar

/ Quenching pressure: from 2 up to 25 bar

/ Quenching gases: N2, Ar, He, H2

/ The best operational features including uniform heating and quenching, ability to harden a wide range of materials and cross-sections

/ ConFlapTM system supporting convection heating

/ Optional equipment for vacuum carburizing technology: FineCarb® / PreNitLPC® and vacuum nitriding LPN

/ A computer control system, operator-friendly

/ AMS2750 specification readiness

Vacuum Furnace Options:

/ Vertical orientation

/ Graphite or metal hot zone

/ Improved temperature uniformity

/ Multi-zone temperature control

/ Load thermocouples port and control

/ High-temperature operation

/ High vacuum or ultra-high vacuum

/ Low and cryogenic-temperature trap

/ Partial pressure control

/ Cooling gas flow direction

/ High-speed cycles with high-pressure gas quench

/ Low consumption of energy, process gases, and other utilities

/ Environmentally friendly with low emissions of process gases

/ Simple design, modular, fitted and adjusted to tasks and plant conditions

/ Guaranteed quality and repeatable process results

/ Predictive maintenance

/ Remote control and monitoring

/ Fast delivery and simple installation

/ Customizable

/ Sintering,

/ Tempering

/ Brazing,

/ Hardening,

/ Low pressure carburizing & nitriding (LPC & LPN),

/ Solution heat treating.

/ Automotive,

/ Machine,

/ Tool,

/ Energy,

/ Medical,

/ Nuclear,

/ Electronic,

/ Metallurgy,

/ Commercial heat treatment,

/ Specialty Application

/ Carburizing steels,

/ HSLA,

/ Alloyed steels,

/ Stainless steels,

/ Alloys and super alloys,

/ Titanium and titanium alloy.

/ vacuum as a protective and technological atmosphere eliminates the need to use harmful process gases and their emission to the environment,

/ no CO₂ emissions, no use of fossil fuels,

/ gas utilization for cooling (nitrogen, argon), captured and returned to the air, neutral for the environment,

/ reinforced thermal insulation saves electricity (approx. 20%),

/ high energy efficiency of used electrical components (IE3 class motors, inverter control, etc.),

/ application of systems and algorithms limiting energy and technological factor consumption (pumping, heating and cooling systems),

/ no harmful substance emissions,

/ reduction of hardening deformations and downstream machining costs,

/ elimination of part washing after heat treatment.