COST-EFFECTIVE MODIFICATIONS IN FURNACE DESIGN

One of the quickest and most effective ways to reduce the energy costs associated with an industrial furnace is to examine its design and verify whether it operates according to its original assumptions. Additionally, it is worth investigating the possibility of introducing structural changes that will reduce the cost of heat treatment. It should be noted that from the time the furnace was commissioned to the present day, the process carried out in it or even the type of charge may have significantly changed.The technical and design solutions originally envisaged by the furnace designer may not be adequate for the current production process. Moreover, during many years of operation, it may have undergone numerous repairs or even modifications, which could result in a change or even deterioration of the functional parameters of the furnace.

To reduce the energy costs of an industrial furnace, it is worth verifying its design and checking whether it operates according to its original assumptions. It is also possible to consider structural changes that will reduce the cost of heat treatment.

Leaks in the furnace can lead to heat loss, increased fuel consumption, uneven heating, additional maintenance, and impact product quality. Regular monitoring and maintenance of furnaces in good technical condition is crucial.

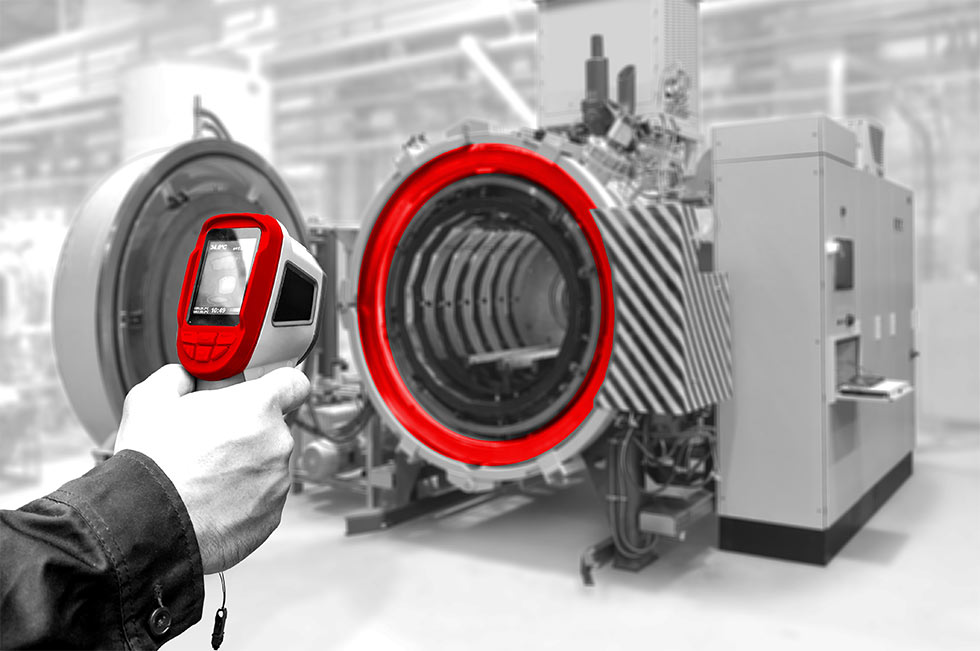

Examining furnace leaks with a thermal imaging camera allows for precise detection of places where heat loss occurs. Once the leaks are located, sealing the furnace can begin, reducing heat loss, improving safety, and increasing efficiency.

Additionally, structural changes can be considered, such as installing additional curtains, automating furnace loading, changing the furnace cycle, and modifying the cooling system for the charge in vacuum furnaces. All structural changes should be designed by experienced specialists and meet safety standards.

/Economic structural changes to the furnace involve:

- Changing the furnace design

- Checking its tightness

- Examining furnace leaks with a thermal imaging camera

- Locating thermal bridges

/Structural Changes

Structural changes in the furnace can reduce heat loss at various stages of the charge processing.

Examples:

- Installing additional curtains and shields to protect the furnace from heat loss and the charge from cooling during transport

- Automating furnace loading to shorten its charging time

- Changing the furnace cycle to make the process faster while maintaining quality parameters

- Modifying the cooling system for the charge in vacuum furnaces to reduce cooling time and gas consumption

It should be remembered that all structural changes to the furnace must be designed by experienced specialists and supported by reliable analysis. Meeting all safety standards is also very important when modifying equipment.

/Checking Furnace Tightness

The drop in the energy efficiency of the furnace may be caused by leaks in the insulation, the furnace housing, or one of its many components.

Leaks in furnaces lead to increased heat treatment costs through heat loss, increased fuel consumption, uneven heating, additional maintenance, and impact on product quality. Therefore, regular monitoring and maintenance to keep furnaces in good technical condition is important.

Examining Furnace Leaks with a Thermal Imaging Camera

Examining furnace leaks with a thermal imaging camera is an effective diagnostic method that allows for precise detection of places where heat loss occurs. The thermal imaging camera records infrared radiation emitted by objects, enabling visualization of the temperature distribution on the furnace surface. This permits the quick and non-invasive identification of problems such as insulation leaks, heating system damage, or moisture.

Locating Thermal Bridges

Thermal bridges are places in the furnace structure where increased heat flow occurs. They can result from differences in materials, their insulation properties, or construction irregularities. Thermal bridges lead to heat energy loss, increased heating costs, and problems such as water vapor condensation and mold growth.

/Sealing Methods for Furnaces

After accurately locating leaks, the most effective and energy-efficient sealing method can be developed.

Each time, it will be a dedicated solution considering the type of device, process, the correct execution and safety.

/Benefits of Sealing Furnaces

/Reducing heat loss

Sealing the furnace prevents heat loss, leading to lower energy consumption.

/Improving safety

Sealing prevents the escape of smoke and flue gases, increasing work safety

/Increasing efficiency

A sealed furnace operates more efficiently, resulting in lower operating costs

What are the economic changes in furnace design?

Economic changes in furnace design refer to technical modifications aimed at reducing operational costs, increasing energy efficiency, and improving the reliability of the equipment. These may include component replacement, optimization of heating systems, and modernization of control systems.

What is the scope of possible design changes?

- Modernization of the heating chamber

- Replacement of thermal insulation

- Optimization of the pump system

- Improvement of control systems

What are the benefits of implementing design changes?

- Reduction of energy consumption

- Lower maintenance costs

- Extended equipment lifespan

- Improved quality of thermal processes

- Increased occupational safety

Do design changes affect the technological parameters of the furnace?

The changes are designed to maintain or improve the technological parameters of the furnace according to production process requirements and applicable standards.

Why is it worth modernizing furnace design?

- Lower operational costs

- Improved energy efficiency

- Extended equipment lifespan