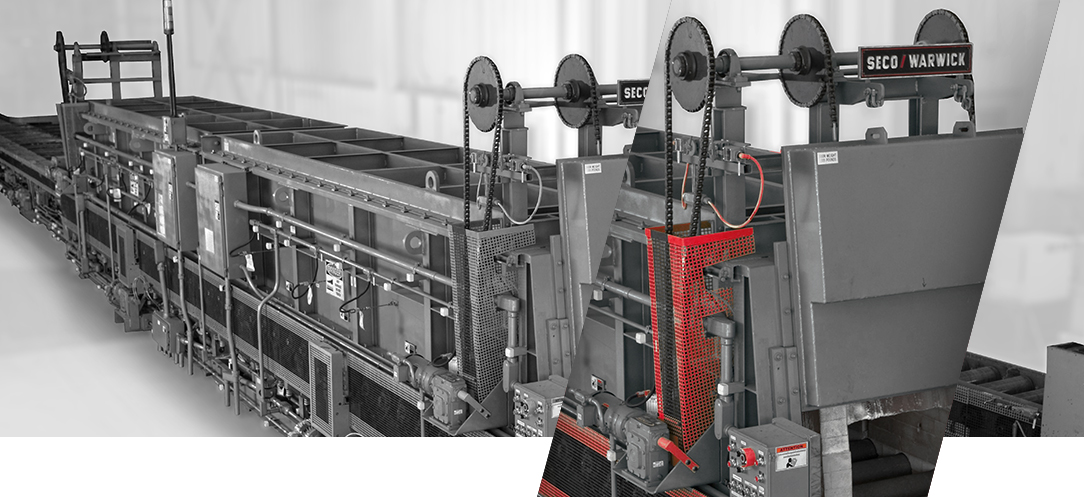

ATMOSPHERE HEAT TREATMENT FURNACE SYSTEMS

Atmosphere heat treatment technologies and equipment

In the production of atmosphere heat treatment solutions, we use our extended experience and state-of-the-art technology to simplify installations, reduce investment costs, and reduce process utilities consumption.

-

Laboratory furnace for fire resistans testRoller hearth furnace for atmosphere heat treatmentMesh Belt type furnacesRotary Retort Furnace Systems

SECO/WARWICK is a world leader and innovative manufacturer of Solution Heat Treatment Furnace Systems with decades of experience. We provide the complete solution to your needs for a custom designed system. Many factors contribute to the overall efficiency of SECO/WARWICK’s solution heat treatment systems. Convection heating using high velocity air distributes heat evenly and efficiently, producing close temperature uniformity. Our time-tested insulation system further enhances efficiency, and has proven to be one of the most durable linings on the market today. A variety of circulated airflow patterns add further efficiencies to our furnace designs.

Retort furnace for gas nitriding process/ Technologies:

Carbonitriding, gas carburizing, hardening, tempering, annealing, spheroidization./ Industries:

aerospace, automotive, bars, bearings, commercial heat treatment, defense, electrical steels, energy, extrusion dies, machinery, saw & blades, springs, steel coils, titanium, transmition & gears, tube & pipes/ Products:

Mesh Belt, Roller Hearth, Fire Resistance, SQ Furance, Rotary Retort/ Unique features:

extended experience in the production of various furnace systems, technological equipment prepared according to customer specifications, we are responsible for technology, logistics, installation, service and training of users – operators./ Operating conditions:

in an atmosphere of air, inert gases (nitrogen), active atmospheres for carburizing and other active diffusion atmospheres, in high temperature systems up to 1000°C/ Application:

our solutions are used in a variety of heat treatment processes, eg: annealing, spheroidization, tempering, solution heat treatment./ Portfolio:

single- and multi-chamber furnaces, furnaces: ribbon, roller, atmospheric generators: endothermic (Endogas ™), atmosphere control and regulating devices.