SECO/TECH

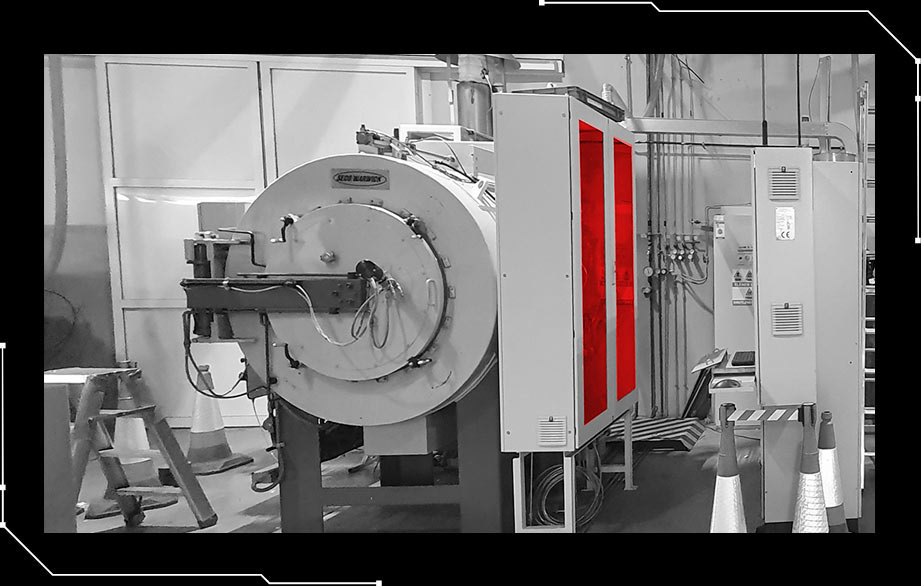

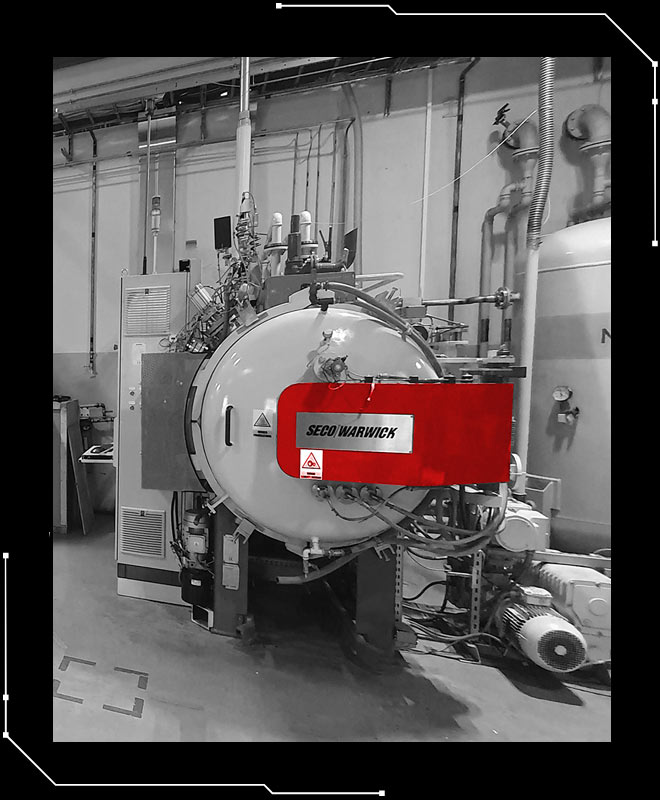

SECO/TECH is a place where advanced thermal and thermo-chemical processes are performed. Tests, trials and commercial processes are all carried out in SECO/WARWICK furnaces.

Each process is monitored online and archived upon completion.

HEAT TREATMENT SERVICES

ON SITE, we perform these processes quickly, efficiently and with appropriate quality:

- CAB (Controlled Atmosphere Brazing) – aluminum and aluminum alloys brazing in a protective atmosphere.

- VAB (Vacuum Aluminum Brazing) – aluminum and aluminum alloys brazing in vacuum.

- Vacuum brazing at a vacuum level of 1×10-5

- LPC (Low Pressure Carburizing) – vacuum carburizing in the temperature range of 860-1150°C using four mixtures of process gases and working pressures in the range of 0.1 ÷ 10 mbar with the possibility of performing the PreNit operation (400 ÷ 700°C).

- SPF (Single Piece Flow) – vacuum heat treatment and LPC vacuum carburizing of single parts in a flow system with 4D Quench® gas hardening for dedicated round components (gears, bearing raceways, etc.).

- LPCN (Low Pressure Carbonitriding) – vacuum carbonitriding.

- LPN (Low Pressure Nitriding) – vacuum nitriding in the gas nitriding temperature range.

- HTSN (High Temperature Solution Nitriding) – high temperature nitriding.

- Gas nitriding using the ZeroFlow method.

- Gas nitrocarburizing with complex atmosphere potential regulation – carbon-bearing atmosphere based on any factor, i.e. CH3OH, CO, CO2.

- Pre- and post-oxidation.

- Heat improvement and hardening in gas (15 bar abs N2) with the possibility of final vacuum nitriding LPN.

- Heat improvement and hardening in quenching oil (any) or polymer medium (any) up to 5 kg of loads.

- Comprehensive normalization.

- Solution heat treatment and aging.

- VIM (Vacuum Induction Melting):

- EC (Equiax Casting),

- DS (Directional Solidifcation),

- SC (Single Cristal Solidification Casting).

The above is performed as:

- Research for SECO/WARWICK sales projects,

- Fulfillment of contract provisions or paid service,

- For external customers.

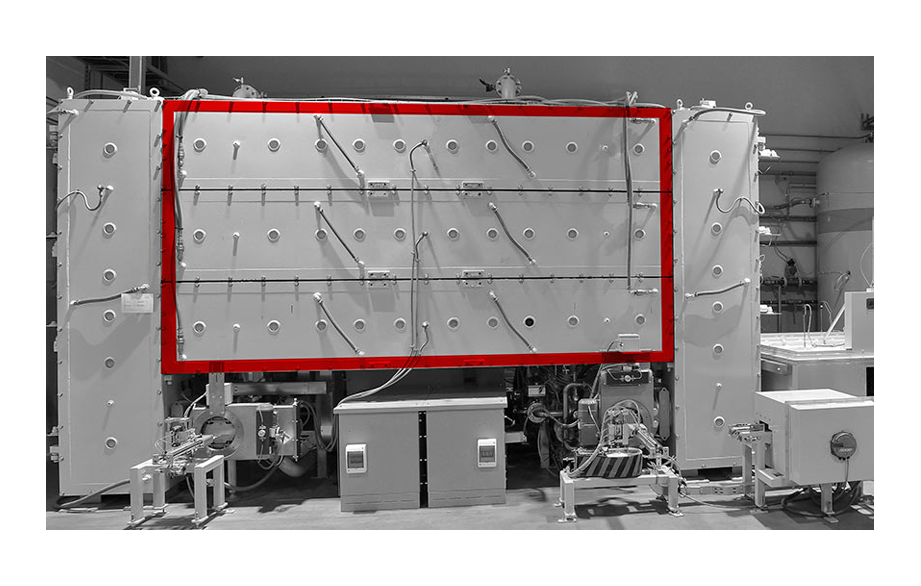

IT WILL BE PERFORMED ON:

WE ARE OPEN TO CONFIDENTIAL CONTRACTS, TO SHOWING THE HALL, FURNACES AND THE LABORATORY WHERE WE CHECK THE PERFORMED PROCESS QUALITY.

BEYOND SECO/WARWICK R&D

It is possible to carry out tests and trials at the Partner’s premises, after appropriate arrangements. In external conditions, heat and thermo-chemical treatments can be performed with appropriate quality to meet customer requirements. Together we can select the furnace and solution that you need.

TECHNOLOGICAL SUPPORT

TRAINING / TECHNOLOGIES / COOPERATION

WE WILL TRAIN YOU IN:

- The basics of materials engineering with emphasis on steels as engineering materials.

- Various levels of heat and thermo-chemical treatment with emphasis on steels as engineering materials.

- Various levels of technology used in SECO/WARWICK furnaces, including the most important ones:

- ZeroFlow,

- FinCarb LPC,

- Utilizing simulators, such as SECO/WARWICK’s proprietary SimVaC, to support every technologist in their daily work.

We will help you with the TECHNOLOGY you use for SECO/WARWICK furnaces in terms of of the analysis of the:

- Assumptions used for the processes performed in terms of the final requirements.

- Recipes used in terms of the results obtained for any number of recipes.

- Recipes used vs. process economy (consumption factors) for any number of recipes.

- Heat treatment schedule in the heat treatment cell for best practices to achieve better profitability.

We are open to any COOPERATIVE project in the field of heat and thermo-chemical treatment technologies.

What are the most common heat treatment processes performed in the SECO/WARWICK R&D lab?

It depends on the current market interest in our products and technologies. Currently, ecological brazing processes of components made of aluminum alloys are being carried out for customers from the automotive industry. A specialized furnace equipped with a pumping system enabling the achievement of high vacuum is used for this purpose.

In addition, a large number of thermochemical treatment processes are carried out, such as:

- Low Pressure Carburizing with High Pressure Gas Quenching,

- and ZeroFlow® gas nitriding and carbonitriding.

One cannot also ignore the classic tool steel heat improvement processes which are carried out using a vacuum furnace. All these processes are carried out using modern and dedicated furnaces, that constitute our company’s product portfolio. Therefore, every customer interested in purchasing a furnace from our portfolio can count on proof tests using the parts or components they process.

In what capacity can you establish business relations with the R&D Department?

The R&D Department is open to any cooperation enabling the realization of the SECO/WARWICK mission. Regardless of whether:

- you are our customer using our furnaces and expect technological support,

- you are in the development phase of a new technology and expect support related to the development of new concepts and conducting research,

- you are interested in our products and would like to find out if they meet your high requirements,

- you need to perform heat or thermochemical treatment of parts or components,

you can count on our interest and commitment. We want to be part of your business and participate in the technological development of your organization.

In case the reader is not familiar with your mission, I think the second part of it fits here: “to create innovative products that provide our customers with reliable, safe and environmentally friendly solutions for heat treatment and metallurgy, and ensure the economic efficiency of their businesses.”

Where do the resources and ideas for the functioning of a department such as R&D come from?

The SECO/WARWICK R&D Department draws resources and ideas from several key sources that support its functioning and development.

- For years, we have been using various grant programs offered by the European Union, which allows us to finance expensive research and development projects.

- We are not afraid to take risks and invest our own funds in innovative projects which can bring long-term benefits.

- Ideas for R&D projects are often derived from the market demand for new products and technologies. The company carefully analyzes the needs of its customers and adapts its activities to their expectations.

- Customers have a significant impact in the direction of product development. Their opinions and needs are key in the decision-making process regarding new projects.

- SECO/WARWICK also develops its own, innovative projects aiming to shape the heat treatment industry. The company strives to be a leader in the industry by introducing innovative solutions.

- Before starting each project, the company conducts a detailed market analysis to identify areas with the greatest potential.

- Each project is carefully assessed in terms of risk and potential benefits, which allows us to make conscious investment decisions.

Thanks to this approach, SECO/WARWICK is able not only to respond to current market needs, but also to shape the future of the heat treatment industry through innovative solutions.