VACUUM FURNACES IN HEAT TREATMENT SYSTEMS

Vacuum heat treatment technologies and equipment

Modern, precise, energy efficient and ecological vacuum heat treatment equipment with guaranteed technology. SECO/WARWICK’s experience in developing these solutions dates back to the 70s of the twentieth century, when vacuum-based heat treatment technologies emerged in the aerospace, automotive, defense, metallurgical, medical, nuclear, and utility industries. Over the last 25 years, the company’s dynamic development has delivered more than 800 complete installations in more than 50 countries, and many of the technologies delivered have become a challenge to traditional technologies.

-

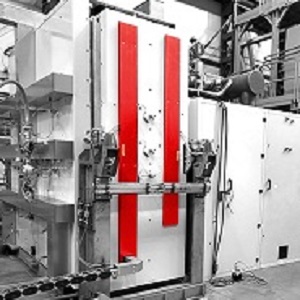

Vector - single-chamber furnaces for heat treatment brazing and sinteringCaseMaster Evolution - double-,triple-chamber furnaces for high volume productionUniCase Master - single piece flow vacuum heat treatment systems for precision in-line productionRetort furnaces for nitriding, tempering, annealing

-

Pit LPC - pit furnaces for low pressure carburizingVacuum Aluminum Brazing technologyIndustrial furnaces for CVI, CVD and purificationCustom designed furnaces/ Technologies:

annealing, solution heat treatment, brazing, sintering, gas and oil hardening (HPGQ), FineCarb® and PreNitLPC carburizing (LPC), nitriding and other special technological processes./ Unique features:

dynamic and efficient heating system, precise temperature control, excellent temperature distribution in the working space, efficient and uniform cooling, compact and modular design./ Industries:

aerospace, energy, defense, medical, machine, automotive, tool, hardening plants./ Parameters:

single-, double- and multi-chamber batch and bulk furnaces, in horizontal and vertical configuration, low-, medium- and high vacuum, radiant and convection heating, low- and high pressure (HPGQ) gas cooling in pressure up to 25 Bar or hardening in oil, full automation, computer control system. Compliance with world safety and quality assurance standards.