In recent years, India has emerged as one of the world’s most dynamically developing industrial centers. This growth is particularly visible in the steel production sector and the metal processing market, which together form the foundation for construction, energy and modern industrial manufacturing. SECO/WARWICK, a leader and supplier of heat treatment and metallurgy equipment, comments on the latest market reports and development prospects in Asia.

Steel production – records and ambitions

In 2024/2025, India achieved a production capacity of 205 million tons of steel annually, reaching the planned target. The country is now heading towards 300 million tons by 2030/2031, as confirmed by a report from MP Financial Advisory Services LLP. The growth rate of steel production in India is one of the highest in the world: 2016–2024: an average of +5% per year (China: 2.76%, world: 1.77%). After 2020: acceleration to +8% per year, while Chinese production began to decline. Currently, projects are underway to expand production capacity by another 167 million tons by 2030, of which as much as 83% falls within the private sector. The government supports the industry through the PLI program for specialty steels, among others.[1]

“Last year, we opened a new factory in India. The plant covers an area of 4,000 m² and is located in a special economic zone near Pune, where a great number of industrial factories—our potential clients—are based. We have thought this investment through very well, as India is one of the fastest-growing countries in the world with enormous production needs. Having our own production facility here relieves us from the necessity of organizing a costly logistics and transportation path for our equipment. It is very important that SECO/WARWICK products keep their high-quality promise regardless of where they are produced. That’s why we conducted a very thorough and extensive training process, which guarantees this quality,” said Sławomir Woźniak, CEO of the SECO/WARWICK Group.

Metal processing market s– strength in diversity

Simultaneously, the metal processing market is developing dynamically. According to Mordor Intelligence, it will achieve an average CAGR of 6.38% from 2025–2030. It includes steel, aluminum and specialty metals as well as services such as welding, CNC, forging, or casting. It is mainly driven by the expansion of domestic production and foreign investments—a growing demand for industrial components; infrastructure development—steel construction for bridges, railways, buildings and power grids; technological progress—automation, robotics, precise digital systems, and also the increasing importance of aluminum and specialty alloys, especially in transportation and aviation.[2]

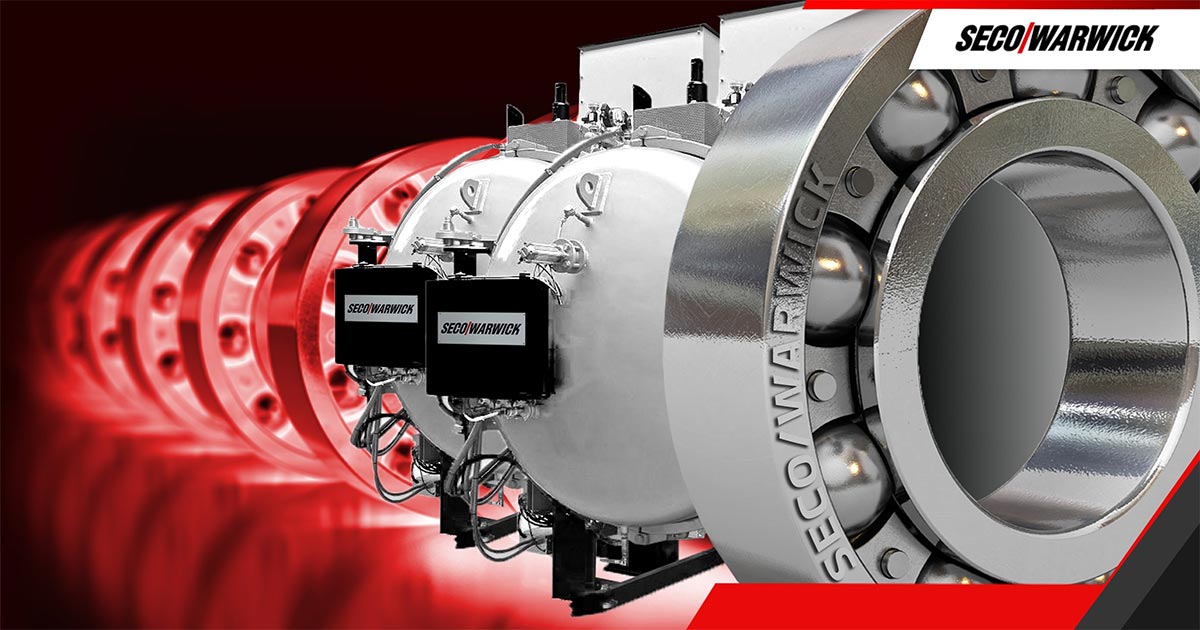

“Local production backed with European and American Technology is our great advantage. Currently, we deliver both CAB lines (including for Narain Cooling Technologies) and the first vacuum solutions produced locally for industry in India. Our current production capacities allow us to manufacture four continuous brazing lines in one cycle or 23 vacuum furnaces. The maximum length of a CAB line produced in our plant will be 63 meters. This secures the needs of even the largest Partners. My mission at SECO/WARWICK is to ensure the Group’s development and provide the high quality known from European and American markets, here in India,” says Arvind Agarwal, the new Managing Director at SECO/WARWICK India.

India – towards industrial independence

Both sectors—steel production and metal processing—mutually reinforce each other, and their development carries significance not only economically but also strategically.

“The development of steel production in India is not only a matter of volume. It’s about economic independence, energy security, and climate responsibility. We are pleased to be part of this new industrial revolution to strengthen our Partners in India,” added S. Woźniak.

Thanks to growing production and technological innovations, India is becoming a global industrial hub, capable of delivering the most demanding projects — from urban infrastructure to energy and defense industry.

[1] https://gmk.center/en/news/india-has-reached-a-steel-production-capacity-of-205-million-tons-per-year-research/

[2] Market Report India Metal Fabrication https://www.mordorintelligence.com/industry-reports/india-metal-fabrication-market?utm_source=openpr