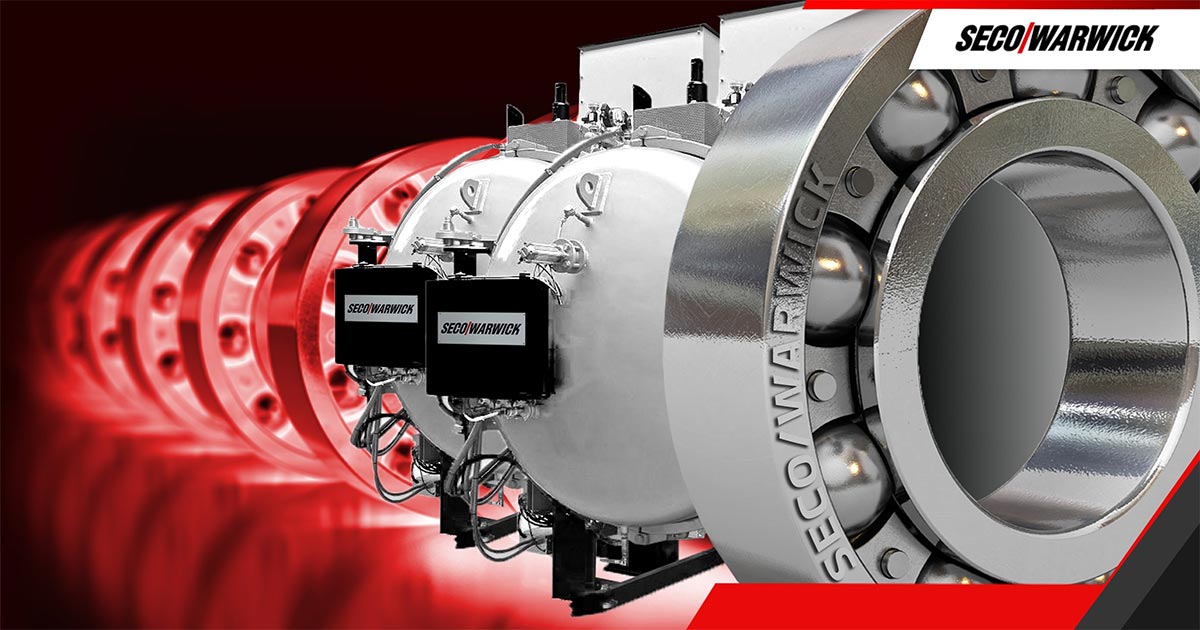

SECO/WARWICK India has signed a contract to supply a vacuum furnace to the renowned precision components manufacturer, Bhuj Polymers. This is an exceptional event for the SECO/WARWICK Group – the single-chamber VECTOR vacuum furnace will be built locally in India under the Made in India program. The equipment is being manufactured at the production plant in Pune.

The vacuum furnace on order will be used to carry out advanced vacuum hardening processes for tools, dies and rolls. The partner will process tool steels with high thermal requirements, such as H13, H11 and D2. Until now, technological capabilities were limited by a locally manufactured furnace with a cooling pressure of up to 4 bar, which did not allow for effective processing of components requiring high-pressure gas hardening. Increasing production loads and customer requirements, including one of the key partners, prompted Bhuj Polymers to invest in next-generation vacuum technology.

“The furnace delivered combines 15-bar high-pressure gas cooling with perfect temperature uniformity and precise control of thermal processes. This solution meets NADCA (tool & die global standard) requirements and is ready for NADCAP (aerospace global standard) certification, enabling Bhuj Polymers to offer vacuum hardening services to the most demanding customers from industries such as automotive and aerospace,” says Maciej Korecki, Vice President of the Vacuum

Segment of the SECO/WARWICK Group.

Think Globally, Act Locally – The SECO/WARWICK Philosophy

For the past two years, SECO/WARWICK has been strengthening the production and engineering competencies of the Group’s local branches. As part of strategic implementations, last year saw the launch of production in India, as well as the expansion of factories in China and the USA. Such measures reduce the logistical costs of orders, increases competitiveness and eliminates challenges associated with global customs policy.

“Bhuj Polymers is a partner who trusted that our vacuum project, carried out entirely in India, was the correct solution for their needs. This trust is of great value to us, as it opened a new chapter in the history of SECO/WARWICK India. This installation is an important step towards building a strong and independent technological infrastructure in India. We are pleased to be part of the growth of companies like Bhuj Polymers, who choose world-class technology produced locally,” said Arvind Agrawal, Managing Director of SECO/WARWICK India.

This event may serve as a significant impetus for other companies, not only in the state of Gujarat. For manufacturers of aluminum die-casting molds, plastic processing tools, or precision components, it is a clear signal that world-class technology is now available locally – with full production, service and advisory support.

“The flexibility and support from the SECO/WARWICK India team on this project was significant. The decision to select both the furnace and the technology partner was driven not only by technical parameters, but also by the proximity of the production plant, the team’s experience and the ability to fully adapt the equipment to local working conditions,” commented Amit Deore, Head Metallurgist from Bhuj Polymers Pvt. Ltd.