The Result of Collaboration Between SECO/WARWICK and the Institute of Mechanical Engineering at the University of Zielona Góra.

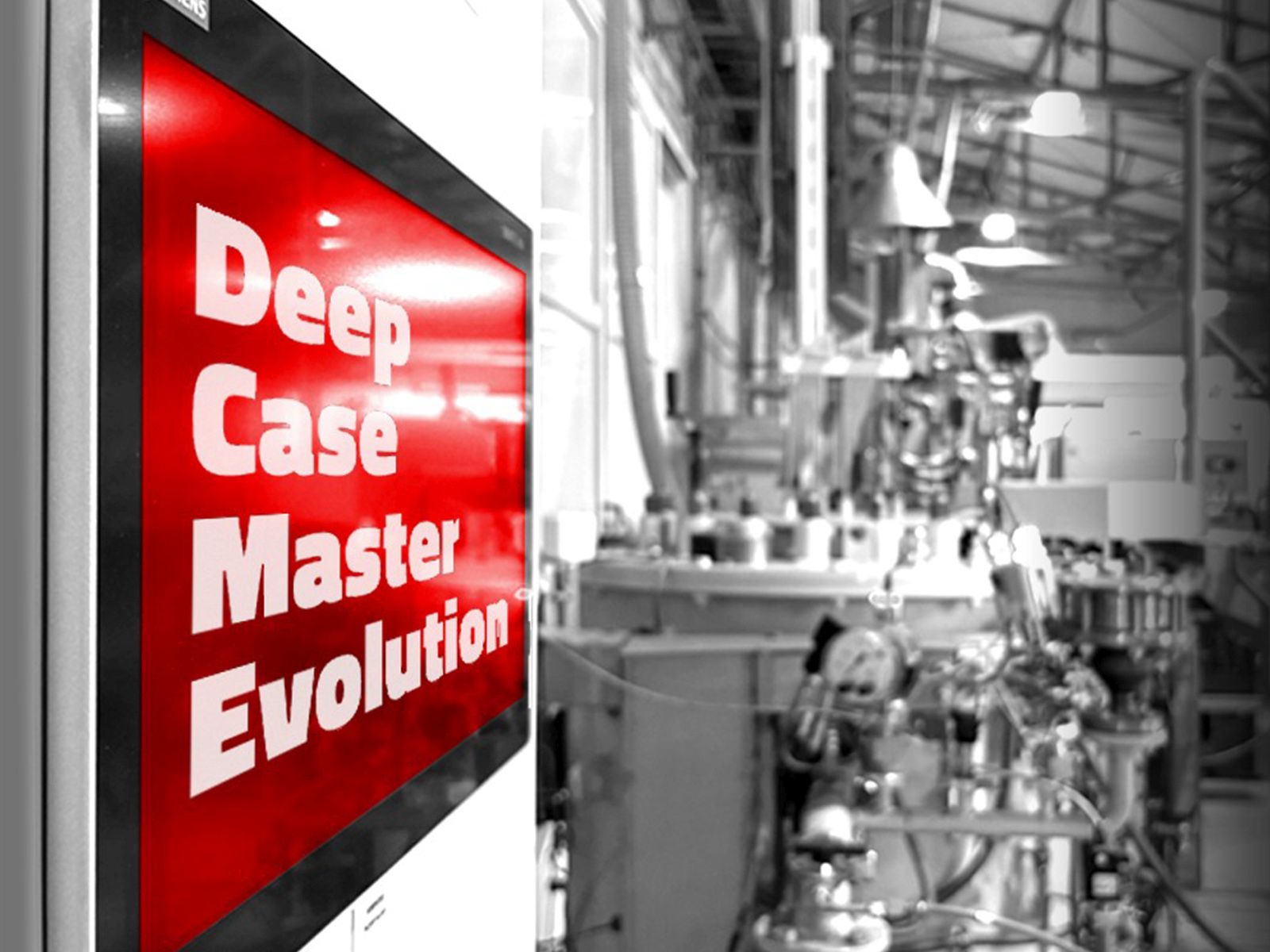

As a result of research and development cooperation between SECO/WARWICK and the Institute of Mechanical Engineering at the University of Zielona Góra, a breakthrough product has been created: the expert next-generation self-diagnosis system for deep carburizing furnaces – DeepCaseMaster Evolution.

This system enables highly efficient low-pressure carburizing processes for critical machine and equipment components, designed to meet the needs of the energy and mining industries.

Developed based on the outcomes of joint R&D efforts, the product targets markets where SECO/WARWICK has been implementing solutions for over 30 years. The proposed solution is both pioneering and unique, with no comparable offerings currently available from competitors.

Significantly Increases Energy Efficiency and Reduces Emissions

The solution developed enables, among other benefits, a reduction in electricity consumption. Lower energy usage in furnaces for manufacturing machine parts for the energy and mining sectors translates directly into reduced atmospheric emissions, which are associated with electricity generation in Poland.

SECO/LAB – Innovation and Education Center

Work related to the development, testing and implementation of Industry 4.0 technologies in the Pit-LPC deep furnace for the low-pressure heat treatment of metals is carried out at the SECO/LAB Laboratory, funded by SECO/WARWICK and located within the facilities of the Institute of Mechanical Engineering at UZ. Current research also includes the implementation of doctorate project DWD/8/0355/2024: “A System for Supporting the Selection of Technological Parameters for Sustainable Low-Pressure Carburizing and Improving the Usability of the PIT Deep Furnace,” conducted by a SECO/WARWICK employee at the Institute. SECO/LAB also hosts classes involving SECO/WARWICK staff, focusing on the practical implementation of Industry 4.0 technologies for students at the Institute of Mechanical Engineering at UZ.