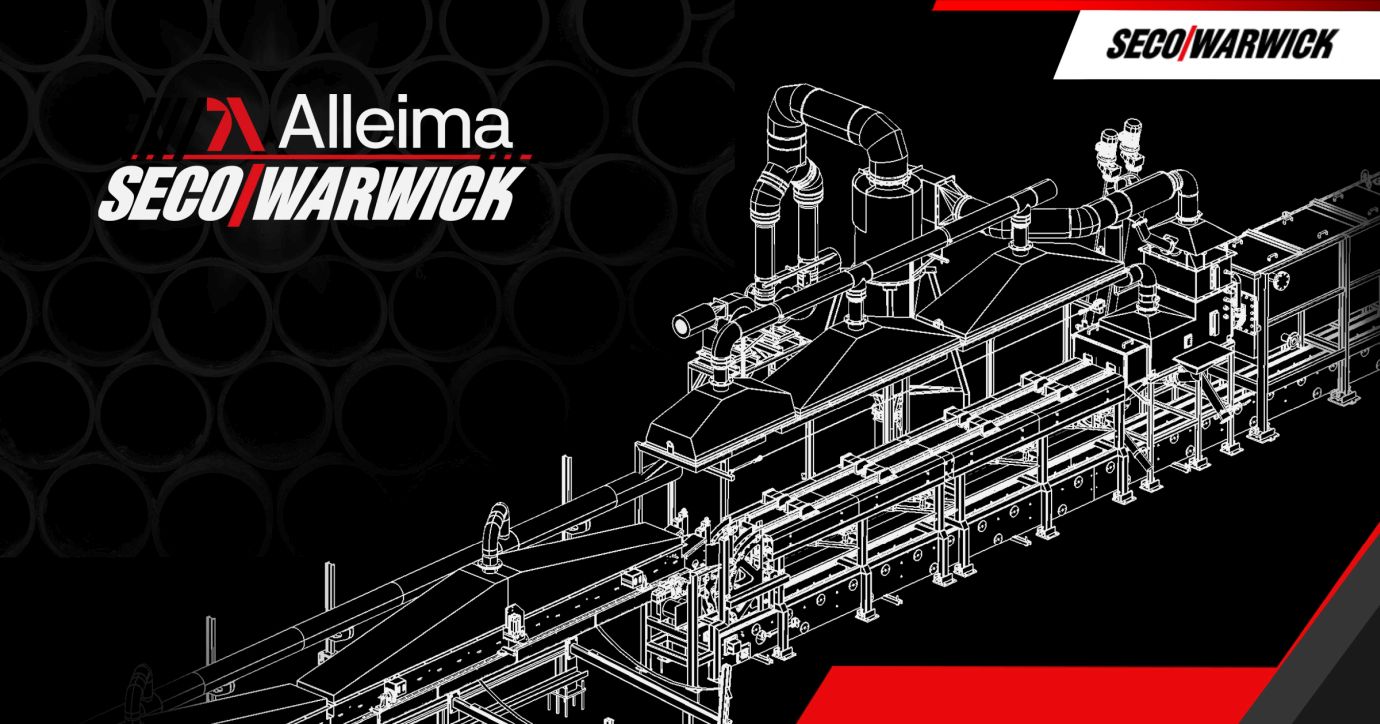

The SECO/WARWICK Group will supply a tube annealing furnace for Alleima - a global manufacturer of high value-added products in advanced stainless steels and special alloys. This is the third line of this type to operate in the company. The partner previously ordered vacuum and retort furnaces from SECO/WARWICK. The current order will be used to produce components for nuclear applications.

The tube annealing system

The electric atmospheric furnace technological line is intended for bright annealing of high-alloy tubes in accordance with the customer’s requirements. Heat treatment in the furnace takes place in a protective atmosphere gas environment and high temperatures. It is worth noting that the success of this project was significantly influenced by the close cooperation between the SECO/WARWICK team and the Partner, as well as by the Partner’s contribution to the development of the implemented solution, based on the experience gained from operating previously delivered equipment.

“The furnace was created specifically for this partner’s needs. It will allow them to increase production capacity in the Scandinavian market. This is important as the demand for high-alloy components in this market has increased. It is an unusual construction, verified through analysis and simulations, and implemented in reality. It offers very good technological results after the annealing process,” explains Piotr Skarbiński, Vice President of the Aluminum and CAB Business Segments at the SECO/WARWICK Group.

SECO/WARWICK’s involvement in the furnace construction

According to expert forecasts, in the next 20 years, Sweden’s demand for electricity will double due to the electrification of industry and transport, in order to reduce greenhouse gas emissions. In winter, during periods of high energy demand, the Swedes are forced to import electricity.

Sweden has 6 nuclear reactors, which account for 30% of energy production. The country’s government recently announced the need to build at least 10 conventional nuclear reactors by 2045. Additionally, new regulations will be introduced to enable the construction of small modular nuclear reactor (SMR) technology.

“Our partnership with SECO/WARWICK has lasted for many years. We are delighted that we could celebrate it in a special way, as our impressively large tube annealing line (over 140 meters long – 460 ft) happens to be the 5,000th SECO/WARWICK device. We feel that together we are creating not only a remarkable history, but also the future as this solution will help us spread our wings,” said Magnus Mellberg, Production Unit Manager at Alleima.

“SECO/WARWICK is a pioneer in modern metal heat treatment technologies used in various industries, including the energy sector. The technical solutions applied in this technological line will achieve the highest strength and structural parameters of the treated elements and ensure the versatility and repeatability of production for different lengths of details. The essence of the project is that we are delivering a custom-made device for the third time, which the client is very satisfied with, and which meets their technical and technological expectations,” said Mariusz Raszewski, Deputy Director of the AP and ATM Sales Department at SECO/WARWICK.