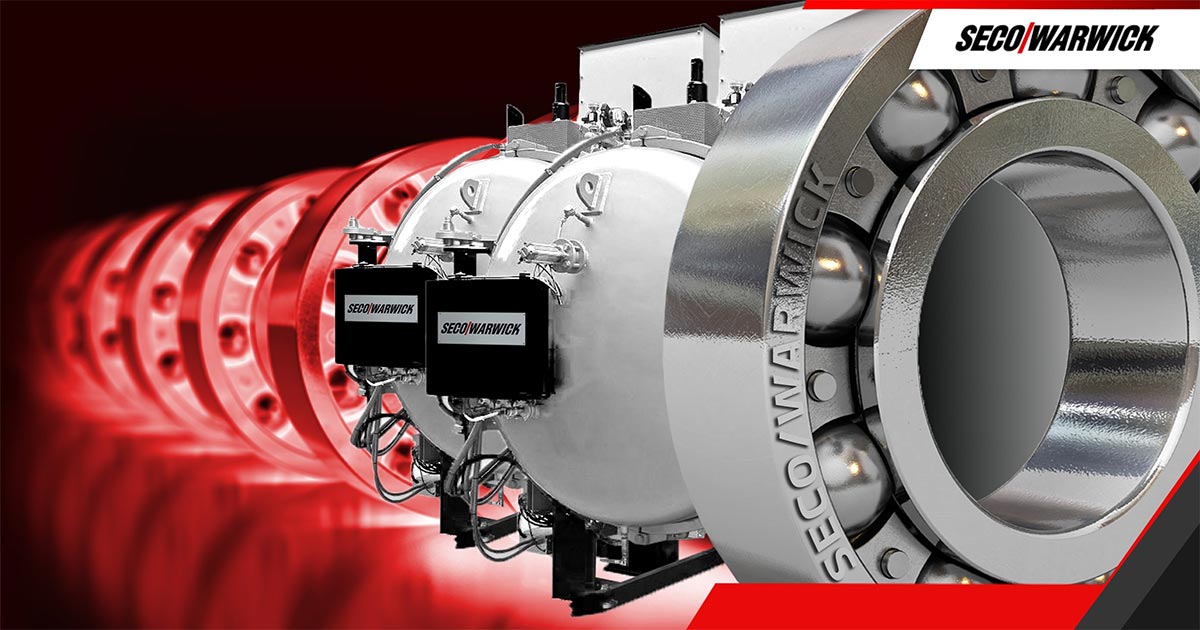

SECO/WARWICK USA has received orders for two identical Vector single chamber vacuum furnaces from a major U.S. bearing manufacturer, reinforcing the company’s position as a leading provider of advanced heat-treatment technology in the North American market.

Each furnace features a 36″ × 36″ × 48″ hot zone, 15-bar high-pressure gas quench (HPGQ), and a horizontal loading configuration, delivering the versatility required for precision heat treatment of bearing components. The low-pressure carburizing (LPC) furnace design, known for performance and process repeatability, provides a scalable platform for both production throughput and metallurgical consistency.

Identical Furnaces, Different Applications

One furnace will augment production capacity at an established aerospace-grade component facility, while the second unit will support a newly acquired plant undergoing a multi-year modernization program. The latter site will use the furnace for a mix of production, specialty geometries, and potential R&D applications as it transitions from legacy heat-treat equipment to state-of-the-art LPC technology.

Both systems include standard SECO/WARWICK options such as a sound enclosure, automatic door, and maintenance platform, as well as customer-specified instrumentation—ensuring compliance with stringent internal quality and traceability requirements.

“These contracts demonstrate how manufacturers continue to invest in advanced LPC technology to enhance throughput, improve metallurgical performance, and ensure long-term processing reliability,” said Piotr Zawistowski, Managing Director of SECO/WARWICK USA. “We are proud to support this customer’s growth and modernization strategy with equipment designed for the highest levels of precision.”