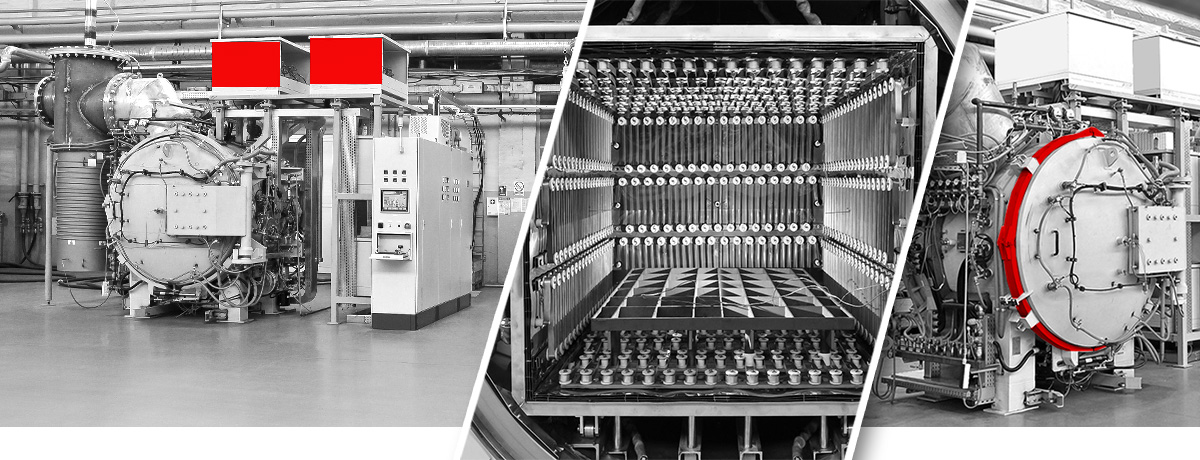

Batch Chamber Furnace

Universal Batch Chamber Furnace VAB

The VAB chamber furnace is a specialized device designed for the vacuum brazing of aluminum. It employs an effective and efficient technology known as no-flux technology. This approach ensures environmental safety and allows for reproducible results. The VAB furnace line is tailored for semi-continuous or batch production of aluminum components, primarily catering to the automotive and aerospace industries.

/ Uniform Temperature Distribution,

/ Consistent Results and Minimization of Non-conforming Products,

/ Easy Loading,

/ Can Be Integrated with Other Equipment (De-oiler),

/ Part Purity/No Oxidation.

Vacuum fluxless brazing provides the advantage of eliminating flux inclusions and designing blind cavities, winding paths, and small transitions in brazed parts. This holds true without encountering the detrimental effects associated with flux removal and flux entrapment after the brazing process.

/ Brazing

/ Automotive and off-road industries,

/ Power generators and power plants,

/ Aviation,

/ Railroad,

/ Electronics,

/ Home devices,

/ HVAC&R.

/ All aluminum alloys that can be brazed with flux can be vacuum brazed. Additionally, some magnesium-containing aluminum alloys (e.g., the 5xxx series), which are not easily brazed using flux, can be vacuum brazed.

/ By employing proper techniques, alloys from the lxxx, 3xxx, 5xxx, and 7xxx series can be vacuum brazed.

/ vacuum as a protective and technological atmosphere eliminates the need to use harmful process gases and their emission to the environment,

/ no CO₂ emissions, no use of fossil fuels,

/ gas utilization for cooling (nitrogen, argon), captured and returned to the air, neutral for the environment,

/ reinforced thermal insulation saves electricity (approx. 20%),

/ high energy efficiency of used electrical components (IE3 class motors, inverter control, etc.),

/ application of systems and algorithms limiting energy and technological factor consumption (pumping, heating and cooling systems),

/ no harmful substance emissions,

/ reduction of hardening deformations and downstream machining costs,

/ elimination of part washing after heat treatment.