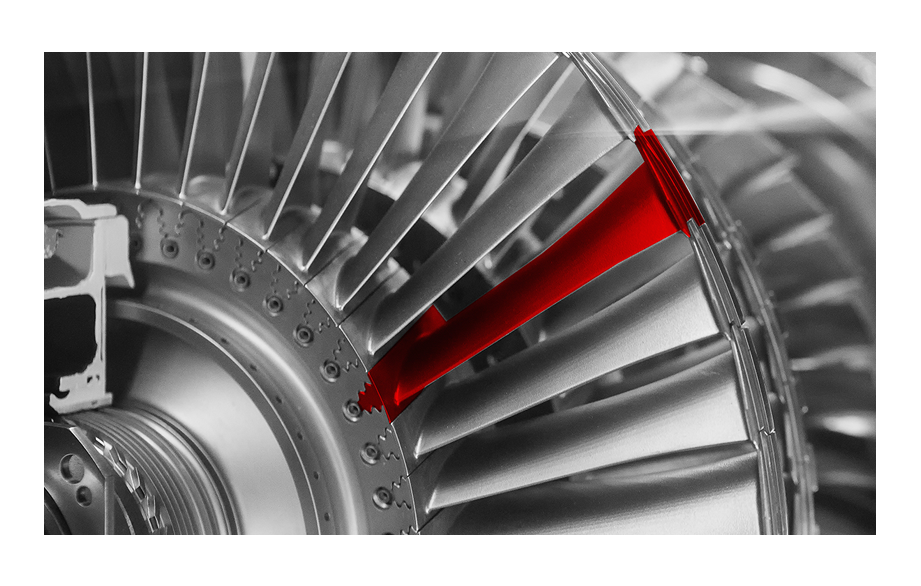

SECO/MELT– VACUUM CASTING

The SECO/MELT R&D Center is where we perform advanced casting in EQ, DS and SC technology for external entities, institutions, universities and commercial customers. Tests, trials and commercial processes are carried out at this location in SECO/WARWICK furnaces.

R&D VACUUM INDUCTION

MELTING CENTER

Our R&D center is equipped with a melting furnace with induction heating for vacuum metallurgy. The capacity of the crucible is 20 kg. This solution / furnace enables users to experience the benefits of Equiax (EQ) castings, as well as Directional Solidification (DS) technology and Single Crystal Casting (SC) using the Bridgman method. We help companies that are starting their adventure with vacuum metallurgy, and those needing confirmation of the possibility of using the selected technology for specific details.

We have the equipment, many years of experience and highly qualified staff – advantages that allow participaticipants to take an active role in the development and testing of a specific technology before purchasing a furnace. Customers have the opportunity to familiarize themselves with the furnace and understand the operation.

At the customer’s request, we can perform processes on test molds, and our specialists from Seco/Lab will evaluate the castings obtained in terms of the desired structure!

What are the limitations regarding materials for testing?

Our furnace can melt materials with a melting temperature of up to 1800oC. It is a furnace with a so-called hot crucible, dedicated to non-reactive materials, such as nickel alloys, cobalt or precious metals. For specific assumptions, melting other metals is also permitted, including reactive ones, e.g. titanium. Each inquiry is considered individually and is analyzed in terms of safety and the ability to carry out tests, as well as how to obtain the best possible results.

How should the Customer prepare for the tests?

We perform tests on our furnace using material and molds provided by the Customer, but it is up to the Customer to agree on who is responsible for providing the melting crucibles. Materials delivered to SECO/WARWICK must include SDS and any other relevant test or certification documents required for the correct handling of the materials and their return to the Buyer after the tests are completed.

What are the safety measures during the tests?

Safety is our priority when conducting tests. Our furnace is subject to regular and cyclical technical inspections, which guarantees its reliability and safety during operation. In addition, all tests are performed by qualified and experienced personnel who are perfectly familiar with both the specifics of our solutions and the safety requirements related to vacuum metallurgy. This allows us to ensure that the processes are carried out in accordance with the highest safety standards, minimizing risk and providing peace of mind to our customers.