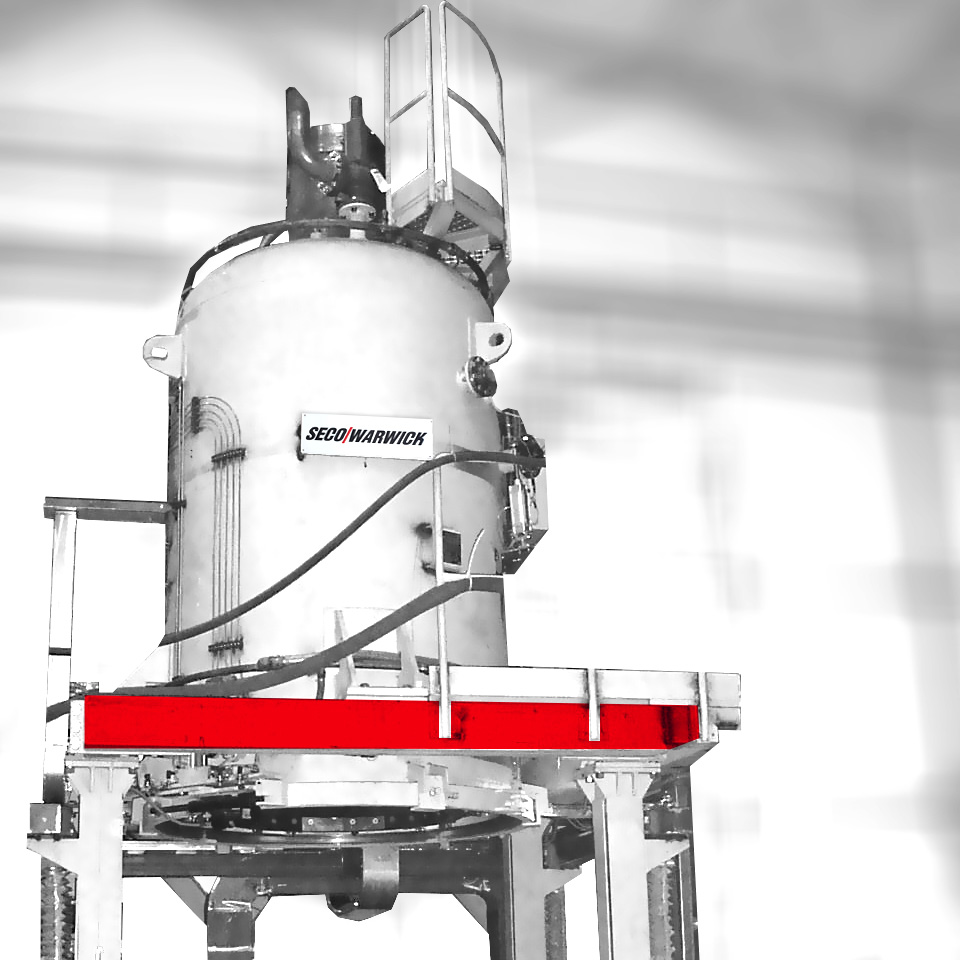

VERTICAL VACUUM FURNACE

COOLING PRESSURE 12 BAR TYPE 12.0 VVPT-EH-32/48N

Vacuum furnace type 12.0 VVPT-EH-32/48N is designed for vacuum heat treatment of heat repaired gas turbine combustion liners, transition pieces, buckets, nozzles and other high temperature alloy parts as per the customer requirements:

/ hardening,

/ tempering,

/ annealing,

/ vacuum brazing,

/ LPC.

General information:

/ Manufacturer: SECO/WARWICK,

/ Year of production: 2004,

/ Localization: Southern Italy,

/ The furnace is operational: testing on site possibility,

/We offer the furnace technical assessment, relocation and installation at the destination place in E.U.

Technical data

Basic data |

|

| Useful dimensions (Æ x H) | 800 x 1200 mm |

| Maximum hearth load | 800 kg |

| Temperature | |

| Maximum temperature | 1350°C |

| * working temperature – vacuum heating | 600 – 1320°C |

| * working temperature – convection heating | 150 – 750°C |

| Temperature uniformity (empty furnace after equalising) | ± 5°C |

| Cooling | |

| Maximum cooling gas pressure | 12 bar absolute |

| Maximum gas pressure during convection heating | max.4bar absolute |

| Vacuum | |

| Ultimate vacuum (clean, cold and empty furnace) | < 5 x 10-2 tor |

| Maximum leak rate (clean, cold and empty furnace) | 1 x 10-3 mbar x l/s |

| Total weight | ca. 12000 kg |

| Vacuum chamber | |

| Material | mild steel |

| Volume | 6,5m3 |

| Cover locking | third clamping flange |

| Hot zone | |

| Materials: | |

| * structure | mild steel |

| * thermal insulation | hard graphite felt boards & graphite foam |

| * heating elements | graphite |

| Heating power | 180kW (3 x 60 kW) |

| Heating zones | three: one on side walls furnace |

| Heating element distribution | all around workload |

| Type of heating elements | low-voltage heating bands and tubes |

| Convection heating fan | 2 kW; 1500 rpm |

| Gas cooling system | |

| Gas inflow | nozzle system – all around load |

| and from the furnace bottom | |

| Hot gas outflow | bung in top |

| Gas blower: | |

| * motor | 3000/1500 rpm; 110/37 kW S2=200Kw |

| Pumping system | |

| Rotary piston pump | 600 m3/h (340cfm) * type |

| * motor power | 5.5 kW |

| Root’s pump | 2000 m3/h |

| * type | WCV1200 KAESR |

| * motor power | 4 kW |

| Vacuum valve | KWW DN100 |

| Instrumentation | |

| Heating elements power control | Continuous |

| Thermocouples | Type S (1off control + 1 off safety) |

| Type K(2 off isothermal quench) | |

| Programmable logic controller | Allen-Bradley SLC-500 |

| Operator panel | Advantech operator interface terminal |

| Temperature controller/programmer | in PLC |

| Over-temperature controller | UDC 100L Honeywell |

| Vacuum transmitter | TTR 216S Leybold-Vacuum |

| * measuring range | 1 x 10-3 – 1 x 103 mbar |

| Partial pressure control range | 10-2 to 1 mbar |