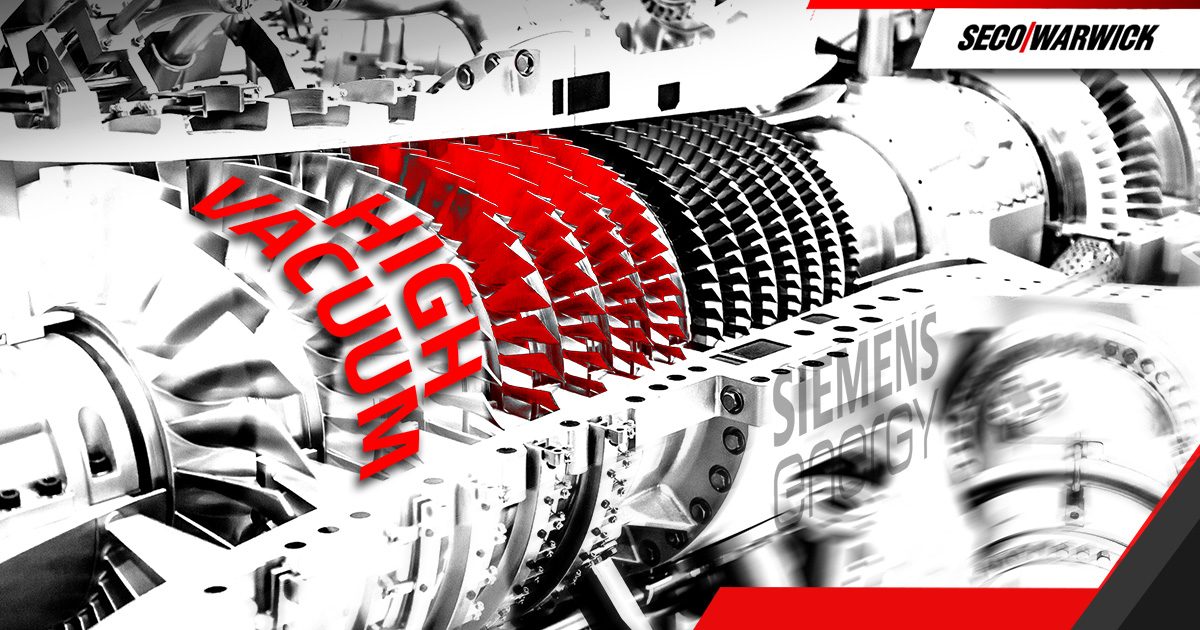

Siemens Energy Global, a renowned manufacturer of heavy duty gas turbines, has chosen the SECO/WARWICK vacuum furnace with screen insulation and molybdenum heating elements. The furnace will be used mainly for brazing gas turbine hot path parts like blades & vanes.

Vector – Low Heat Loss and Good Temperature Distribution

The device on order produces very efficient and clean vacuum processes in high ranges, thanks to the use of a very good system consisting of a mechanical pump, an efficient Roots pump, and a diffusion pump. The advantage lies in the molybdenum heating chamber which ensures the required temperature distribution, and provides very high process cleanliness.

“The Vector vacuum furnace solves the Partner’s problem of heat treating an increased number of large blades & vanes requiring a high degree of cleanliness in both the brazing and annealing processes. The most important problem is handling the constantly growing production. The Vector will relieve the production burden on the current equipment in operation in the client’s manufacturing & repair facility in Berlin. This is the second furnace that we will deliver to one of the largest turbine blade & vane manufacturers. The key to this order was the guarantee of high efficiency without loss of quality,” said Maciej Korecki, Vice President of the Vacuum Segment, SECO/WARWICK Group.

The efficiency of the heat treatment processes is also influenced by the ability to cool at 1.5 bar in argon. Thanks to the inverter control, we can activate optimal cooling power during the appropriate stage of the process.

Individual Specification – the Key to Success

The unique features of this device are primarily due to the modifications that enable very clean blade & vane brazing processes.

“We worked long and hard to ensure that the furnace met all the needs and precise requirements of Siemens Energy Global. We used a molybdenum heating chamber, partial pressure system, dew point sensors, and a very efficient high vacuum system. An important aspect is also the fact that the furnace will be integrated with the client’s master system using the OPC Unified Architecture communication protocol. Thanks to this, we can connect with a wide range of machines and industrial devices. Thanks to simple integration with our devices, Partners can monitor the efficiency of entire production lines in real-time,” commented Grzegorz Głuchowski, Sales Manager, SECO/WARWICK.

Gas Turbines – The Future of the Energy Industry

Gas turbines are used in power plants to produce electricity. Their high efficiency and quick start-up make them ideal for covering peak energy demands. Gas turbines are used in the industry as a source of electricity and technological heat. They are used for many applications including oil refineries, chemical and petrochemical plants, where a large amount of process steam is required.

“This is our second SECO/WARWICK vacuum furnace. It has been adapted to our unique needs and integrated with the machine park thanks to the OPC UA protocol. It will be an important element of the production process, which focuses on green energy. The furnace will be installed in our German plant,” – according to the Siemens Energy Blades & Vanes division in Berlin.