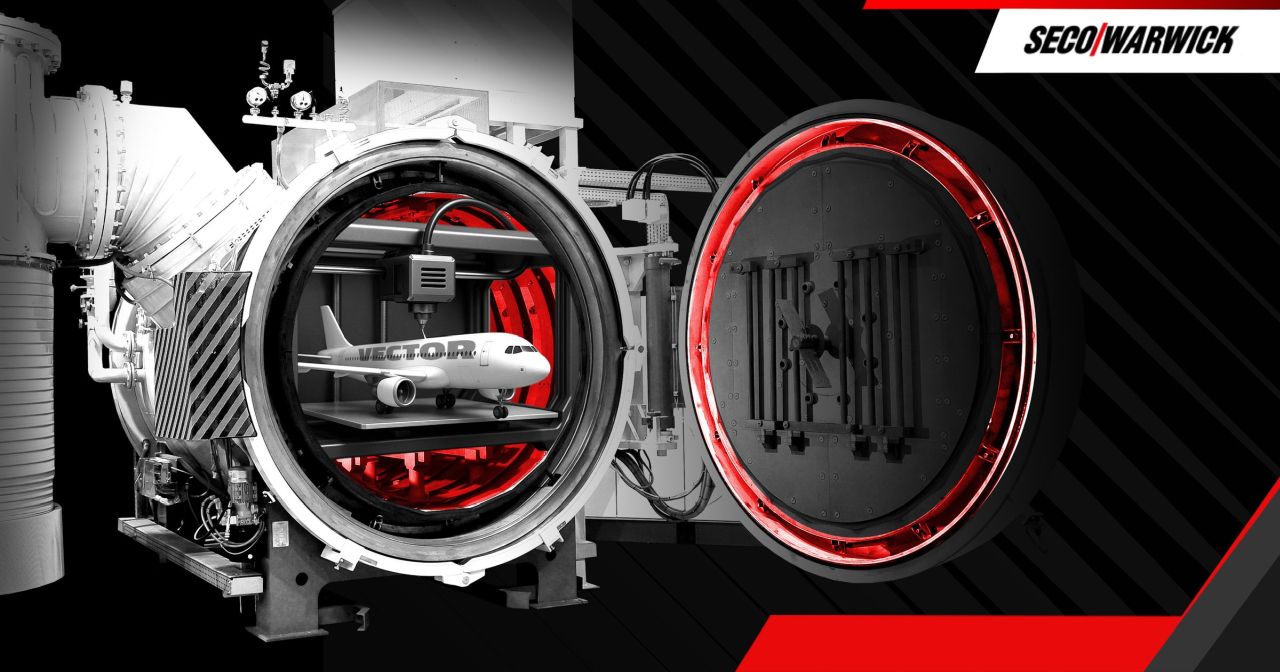

SECO/WARWICK has signed a contract to supply a vacuum furnace with gas cooling up to 6 bar abs. for one of the leading manufacturers from Central Europe. The partner, who had previously used SECO/WARWICK vacuum metallurgy technology, decided to expand their machine park in connection with the intensive development of a new activity area – 3D printing technology for the metal components used in the aviation and energy industries.

The new SECO/WARWICK device will support advanced stress-relieving and hardening processes for additively manufactured elements.

The furnace on order is tailored to meet the requirements of stress-relieving processes for large components produced using additive technology, as well as highly controlled hardening processes. The increased working space (900 x 900 x 1200 mm) and an advanced vacuum system enables very clean processes while maintaining the parameters necessary to process highly complex and heavy parts.

“The new investments of our partner in 3D printing are among the most dynamic undertakings in the field of precision metalworking in Central Europe. Our device is a key element in the chain of post-processing technology and has been designed to perfectly respond to the needs related to annealing and stress removal in additively manufactured elements,” comments Maciej Korecki, Vice President of the Vacuum Segment at SECO/WARWICK.

The vacuum furnace is equipped with an efficient high vacuum system (HPGQ) based on two SV300 Leybold pumps, a Roots WH2500 pump, and an HS-32 AGILENT diffusion pump, allowing for vacuum in the 10⁻⁴ mbar range. The device also features a partial pressure system for technical gases, which counteracts the sublimation of alloying elements and contamination of the hot zone. An extremely important addition is the dew point sensor, which protects against moisture condensation in the heating chamber and minimizes the risk of oxidation of the batch surface.

“We are proud to see how our solutions support the development of modern technologies. More and more customers are implementing 3D printing, but to fully leverage its industrial potential, advanced infrastructure is needed. Our branded furnace meets these needs – it ensures cleanliness, parameter control and scalability, which is everything today’s aviation and energy industries require,” adds M. Korecki. “This is another joint implementation with this Partner and confirmation that we are building long-term relationships with companies that bet on innovation and quality.”

The partner plans to use the device primarily for post-3D printing stress-relief processes, but also for hardening turbine and engine system components. Thanks to cooling in an inert atmosphere up to 6 bar abs. with inverter-controlled blower operation, it is possible to carry out isothermal processes with high repeatability and predictability.

The device on order constitutes an important element of the client’s broader investment program focused on the development of future technologies in the aviation and energy industries.