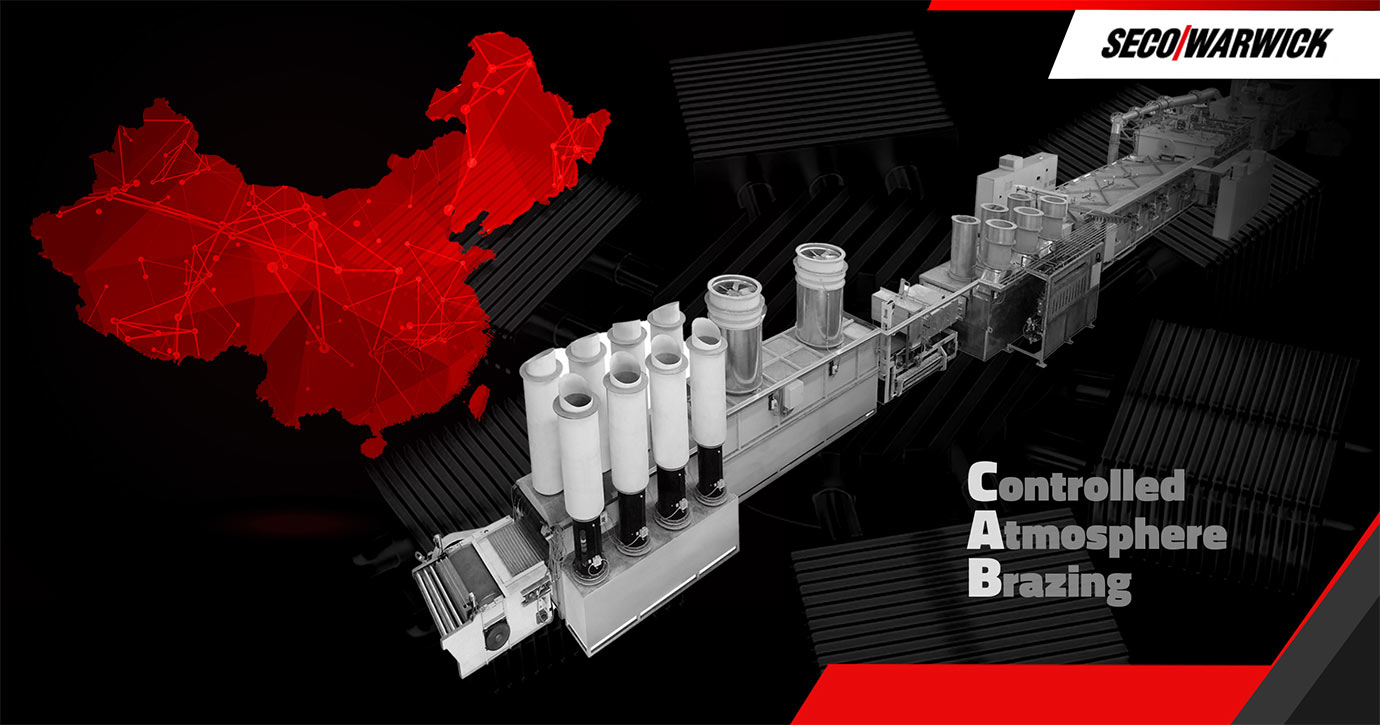

The SECO/WARWICK Group will deliver a continuous Controlled Atmosphere Brazing (CAB) line to a Chinese manufacturer specializing in thermal solutions. This is the first project carried out for this Partner. The equipment will be used to braze a variety of components, ranging from cooling plates for data centers to parts for rail transport.

Aluminum brazing in a Controlled Atmosphere (CAB) is the preferred technology for manufacturing aluminum heat exchangers in the automotive industry. But not only that.

The CAB line on order featuring a 1000 mm (39.2 in) belt width, will consist of several key components. The CAB (Controlled Atmosphere Brazing) line with a 1000 mm belt includes a Dry-Off Oven for moisture removal and part preparation, a Radiation Brazing Furnace that performs brazing in a controlled atmosphere, a Clean-Out Chamber designed to eliminate process residues and stabilize internal conditions, an Air-Jacketed Cooling Chamber, and a Final Cooling Chamber which cools components to a safe temperature for further processing or transport. The entire system is complemented by an integrated control and process management system. The system will be equipped with a dedicated control system.

“What makes this project unique is the ability to braze two distinct product groups—3D-VC (3D vapor chambers) and cold plates—on a single line. Thanks to precisely calculated throughput and a specially tailored cooling system, the line ensures exceptional temperature uniformity and process repeatability, which is crucial for the high quality of components used in modern technologies,” said Piotr Skarbiński, Vice President of the Aluminum and CAB Products Segment at SECO/WARWICK.

The 3D Vapor Chamber is a three-dimensional heat spreader based on the liquid phase change phenomenon. This component is used, for example, to cool processors in data centers. Cold plates, in turn, are efficient heat exchangers that dissipate heat from electronic components using coolant that flows through a specially designed metal plate. They are primarily used for cooling traction batteries in electric vehicles (EVs).

A Solution Supporting the IT Sector

The Chinese Partner is an innovative technology company specializing in heat management solutions. Among the key areas of the company’s operations are temperature control platforms for aircraft engine testing, research systems for power electronics, and the design and manufacture of cooling systems. The company provides solutions to various industries, including aviation, photovoltaics, e-mobility, data centers, and rail transport.

“Modern electronics—AI, EVs, servers, Industry 4.0—generate immense amounts of heat on very small surfaces. 3D-VC and cold plates are technologies that effectively dissipate this heat, ensuring system reliability and efficiency. This order confirms that SECO/WARWICK provides solutions precisely tailored to rapidly developing sectors. We utilized a proven, standard design that, in this project, was adapted for very specific and demanding industrial applications. Our experience and the quality of our technology earn us the trust of new clients, even in highly competitive and advanced industries like IT system cooling and rail technologies,” added Liu Yedong, Managing Director of SECO/WARWICK China.

The dynamic development of cloud technologies, artificial intelligence, and real-time data processing is driving demand for high-performance cooling systems. As a result, the need for advanced equipment for brazing aluminum components, such as cooling plates, is also increasing. This translates into growing demand for SECO/WARWICK CAB aluminum brazing lines.