Modifications, Services and Spare Parts for Aluminium

SECO/WARWICK provides field technical support and replacement parts for all equipment manufactured inhouse. SECO/WARWICK has successfully provided both parts and rebuild services for other manufacturers as well. Technicians are available for equipment breakdowns, rebuilds, upgrades, relocating equipment, troubleshooting, and preventative maintenance.

/ Heating elements and gas equipment

/ Gas burners spare parts; UV probes, spark electrodes and complete burner inserts

/ Motoreducers along with assembly sets

/ Customized chain drives

/ Oxygen analyzers and measuring cells

/ Gas reducers

/ Pumps and assembly elements

/ Cooling units filters, in example for Bypass Coolers

/ High temperature bearing assemblies

/ Load trays

/ Control cabinets components; frequency inverters, PLCs, thermocouple modules, etc.

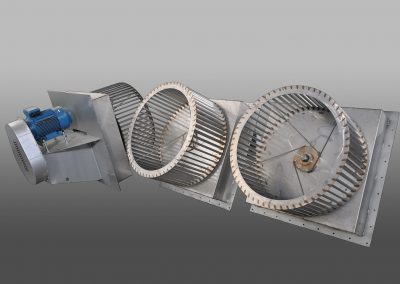

/ Various fan designs

/ And many more upon request

/ Worn out thermal insulation retrofit. Same or better parameters offered

/ Redesign and retrofit of load trays in order to meet new process requirements

/ Existing loading systems adaptation to new delivered equipment

/ Change of the old burner system and adaptation to current norms. Providing more efficient solutions, such as self-recuperative burners

/ Exchange of electric heating elements in the existing equipment

/ Retrofit of control cabinets in order to meet the most up to date norms and standards

/ Exchange of electric drives for new models with higher ampere-hour efficiency

/ Upgrade of the atmosphere flow inside the heating chamber thanx to the internal arrangement redesign

/ Closed loop water cooling systems installation in the existing water tanks

/ Software upgrades, adding new functionalities or new interface development according to the Customer’s expectations

/ Adding the protective atmosphere systems to the existing furnaces

/ Adding oxygen analyzer or lambda probe to the existing atmosphere systems