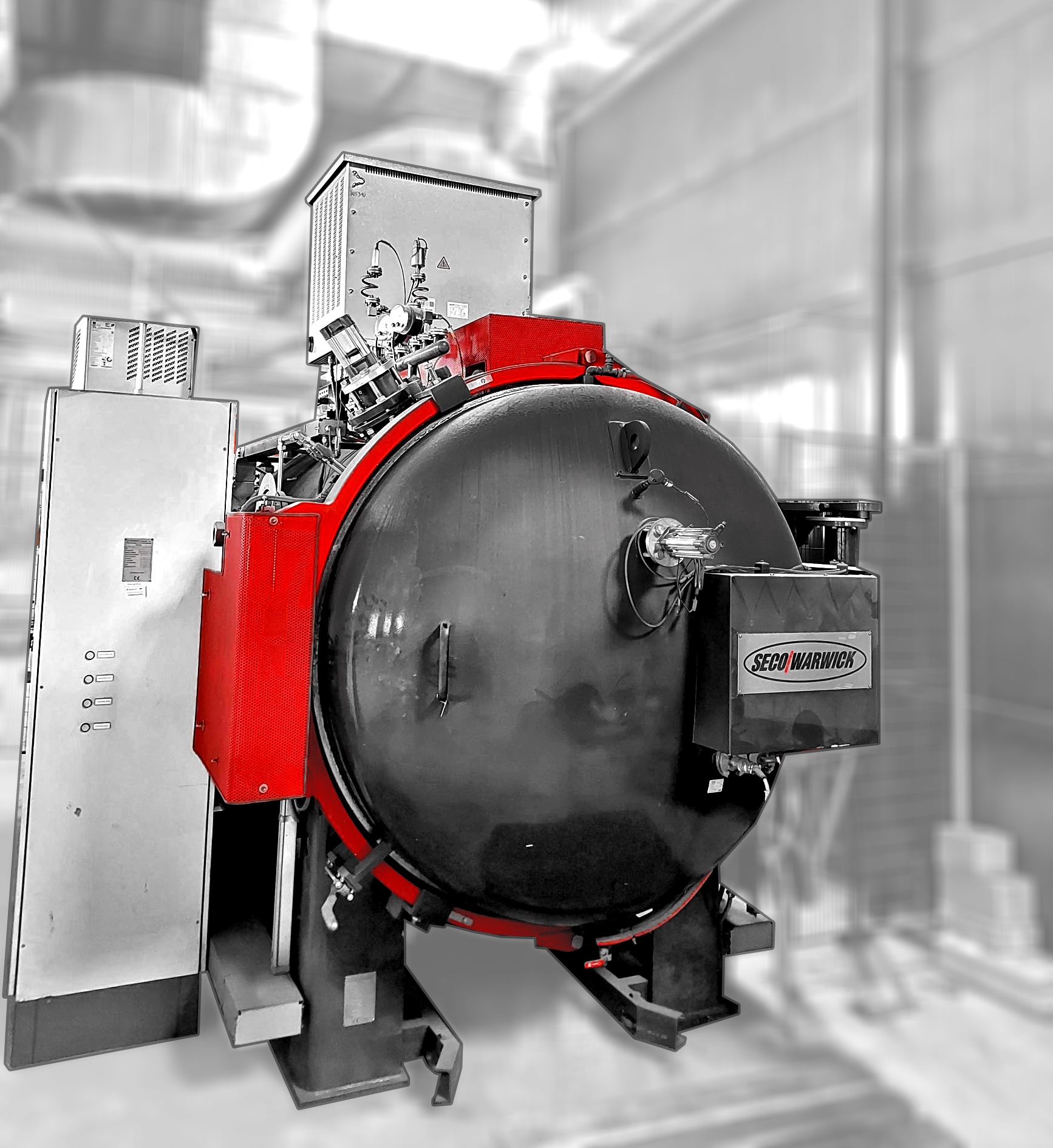

Vacuum furnace with gas cooling under pressure of 15 BAR and vacuum nitriding option LPN TYPE 15.0 VPT-4035/36LPN

General Information:

/ Vacuum furnace with gas cooling under a pressure of 15 bar with vacuum nitriding function

/ Manufacturer SECO/WARWICK

/ Year of production 2015

/ Location – Northern Poland

/ The condition of the furnace was checked by the manufacturer in June 2025 – available report

/ Along with the furnace, a complete cooling system with a fan cooler, nitrogen buffer tank, and loading trolley!

/ The furnace has not been used, except for initial startup!

/ We offer relocation and installation of the device at the destination!

Technical Data

| Working zone – Useful dimensions (W x H x L) | 600 x 600 x 900 mm |

| Maximum load gross weight | 800 kg |

| Temperature | |

| Nominal temperature | 1300°C |

| Temperature uniformity: | |

| – from 150°C up to 750°C in convection gas ± 5°C | |

| – from 600°C up to 1150°C in vacuum ± 5°C | |

| Vacuum | |

| Operating vacuum | 5×10-2 mbar |

| Ultimate vacuum (clean, dry, outgassed, cold and empty furnace) | 1×10-2 mbar |

| Leak rate (clean, dry, outgassed, cold and empty furnace) | <3×10-3 mbar_l/s |

| Partial pressure control range | 10-1 ÷ 10 mbar |

| Hot zone | |

| Structure material mild steel | |

| Thermal insulation 40 mm thick CFC-faced hard felt graphite boards backed by 10 mm thick soft graphite | |

| Heating system | |

| Heating elements low-voltage graphite bands | |

| Heating elements distribution all around workload | |

| Heating power | 150 kW |

| Number of heating control zones | 1 |

| Heating power control mode variable frequency drive | |

| Convection heating | |

| Convection atmosphere (gas / pressure) | Nitrogen / 1÷3 bar abs. |

| Convection fan | 2,2 kW |

| Motor control mode variable frequency drive | |

| Vacuum pumping system | |

| Rough vacuum pump SV300 Oerlikon Leybold | nominal pumping speed 280 m3/h |

| Root’s pump WH700 Oerlikon Leybold | nominal pumping speed 1500 m3/h |

| Furnace vessel | |

| Material mild | steel |

| Volume | 5,5 m3 |

| Door locking mechanism Third clamping ring operated by electrical linear motor | |

| Gas cooling system | |

| Quenching gas nitrogen | |

| Max. quenching pressure | 15 bar abs. |

| Blower motor 2SKPW250-2A | |

| motor power S2=180 kW; S1=110 kW | |

| control mode variable frequency drive | |

| Cool gas inflow nozzles all around the load and front door | |

| Hot gas outflow window in rear wall | |

| Instrumentation | |

| Control and over-temperature thermocouples | 1 off, double, type S |

| Load thermocouples | 2 off, type N |

| Fine vacuum transmitter | TTR-91S / Oerlikon Leybold |

| High vacuum transmitter (OPTIONAL) | PTR-90 / Oerlikon Leybold |

| Control system | |

| PLC S7-1500 / Siemens | |

| Operator’s interface | Siemens TP1500 |

| 15” Touch screen | |

| Over temperature controller | 3216i Eurotherm |

| Variable frequency drives Danfoss | |