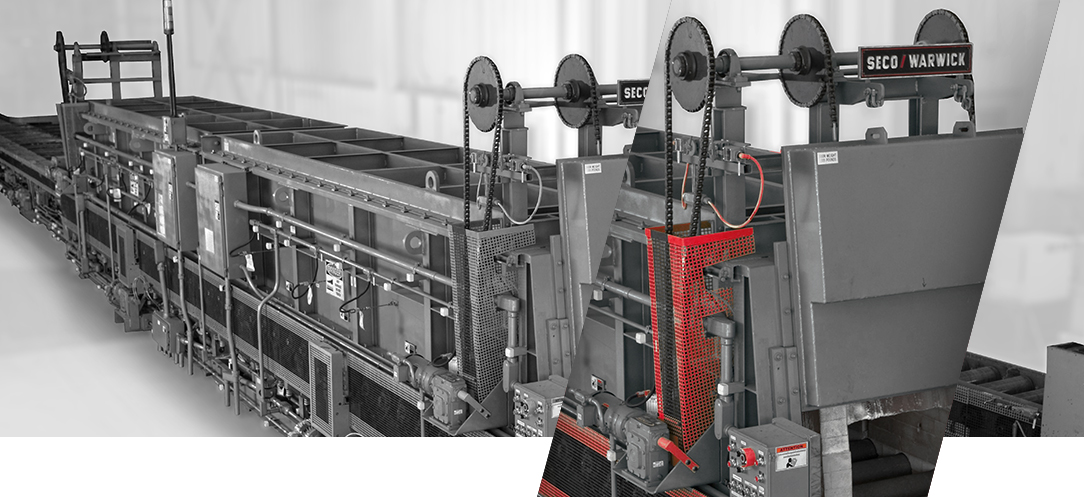

Roller Hearth furnace for atmosphere heat treatment

A variety of atmosphere heating and cooling chamber designs

SECO/WARWICK Roller Hearth furnaces are designed to heat treat a wide variety of products economically with uniform, repeatable results for annealing, hardening, and other processes. There’s a wide range of sizes of electric or fuel-fired heating systems with matched cooling sections and material handling systems. Coupled with a protective atmosphere to keep product clean or to assist in surface treatments, the Roller Hearth furnace is a powerful tool for today’s manufacturing environment.

You can gain:

/ Energy recuperation is easier and less costly with continuous systems

/ Continuous takes up about half of the floor space than multiple batch units

/ Longer equipment life – typically 40+ years

/ Temperature ranges from 400°F – 2250°F (200°C – 1,200°C)

/ Suitable for atmospheres from air or products of combustion to exothermic (EXOGAS™), Endothermic (ENDOGAS™), Nitrogen/Hydrogen or Ammonia (AMMOGAS™) or steam

/ Throughputs are unlimited but typically from 500 pounds (225 kg) to 15,000 pounds (6,800 kg) per hour

SECO/WARWICK is one of the top global manufacturers of Roller Hearth furnaces. Our process specialists select the right combination for your production by configuring the furnace system with a variety of heating and cooling chamber designs, custom engineered to suit your process.

Roller Hearth furnaces are ideal for full anneal of steel casings to improve machinability. These may also be used for stress relief anneal of castings or forgings. This furnace can be gas fired direct, gas radiant tube or electric ribbon resistor. Water jacketed cooling chambers are designed to cool rapidly, to work with excess air burners, and to improve convection heat transfer at the lower temperatures.

/ Continuous, Unlimited Work Flow: Roller Hearth conveyor system consists of a series of externally driven rolls. There are no cumulative conveyor pressures or tensions as in belt, chain or pusher furnaces. As a result, there are no production or cycle limitations and the length of the furnace is dependent only upon your application needs. Individual operation of the roll sections permits continuous or interrupted workflow.

/ Fast, Top QualityProduction: The advanced construction design features of these furnaces let you increase both the quality and rate of your production. Individually driven roll sections for fast run-in and run-out, heavy-duty insulation systems, welded gas-tight casings, temperature-designed doors-all assure fast, accurate, uniform heating and cooling, minimizing atmosphere mixing, heat loss and work distortion or stress.

/ Ease of Installation: Furnace sections are completely assembled at the factory with insulation, heating systems, piping, wiring, and rolls. The skid-mounted sections can be moved quickly and easily into place, welded or bolted together and placed in operation. Assembly by highly skilled factory staff using the right tools, jigs and fixtures assure greater attention to workmanship and design details, eliminating many of the problems frequently encountered with field construction.

/ Approach to extend component life: Because individual conveyor rolls are externally driven and remain in the same temperature zones, they are not subject to thermal cycling and can be designed for maximum operation life at working temperatures. In addition, cumulative pressures on conveyor rolls, work trays and workloads are eliminated. Furnace doors are specially constructed and insulated for operation within the temperature zones in which they are located, minimizing stress and warpage caused by temperature differences. Heating and cooling sections incorporate dependable, high-quality components for long life operation. Factory assembly of the furnace section eliminates many problems often encountered with field construction.

/Flexible Operation: Individual roll sections can be started, stopped, reversed or oscillated; they can be run at the same or different speeds. This permits an operating furnace that produces your required cycle in a minimum amount of space. High-speed transfer between sections allows closely spaced workloads or work trays, with separation during transfer through doors, assures the optimum use of hearth space and minimizes atmosphere mixing. All door openings can be adjusted to workload heights, permitting faster operation and minimizing atmosphere mixing

/ Lower Product Costs: The wide selection of furnace combinations and sizes means that you can get the furnace designed for your needs. You can cut costs through increased product quality and rate of production. Factory assembly means lower cost installation and your furnace is in production more quickly. In addition, the best construction materials and design mean minimum maintenance.

/ Cycle Annealing: Cycle annealing produces a tough, uniform structure in steel. A Roller Hearth annealing furnace can improve the machinability of screw machine stock, improve cold working properties of deep drawing stock, and improve impact resistance & fatigue properties of gears or machine parts. In the furnace, the steel is heated to slightly above hardening temperature (approx. 1700°F/925°C), cooled quickly to the temperature at which transformation should take place (approx. 1200°F/650°C), held at this temperature until the transformation has taken place and then cooled. This furnace may be heated by gas-fired radiant tubes or by electric ribbon resistors, and normally has a controlled atmosphere to prevent scaling and surface decarburization. Maximum furnace temperature: 1750°F/950°C.

/ Copper Brazing: Expensive forged or machined parts can frequently be replaced by copper brazed assemblies of stamped parts. In many cases, the copper brazed parts offer a quality improvement as well as a cost reduction. The copper brazing furnace normally includes an electrically heated chamber with either alloy ribbon resistors or silicon carbide resistors and a water-jacketed cooling chamber. Copper brazing furnaces are operated with a reducing atmosphere to prevent oxides from interfering with the brazing operation. Maximum furnace temperature: 2100°F/1150°C.

/ Magnetic Punching and Lamination Annealing: A choice of higher component efficiency or lower costs can be achieved in electric motors, transformers, reactors, and ballasts by annealing the magnetic laminations after the last punching, shearing or welding operation has been performed. With almost any magnetic steel, the losses are reduced by this final anneal. The furnace normally includes a burn-off chamber to remove lubricants, a heat and hold the chamber, a slow cool chamber and an air blast cool. Heating may be by gas-fired radiant tubes or electric ribbon resistors. The furnace is operated with a carefully selected controlled atmosphere. Maximum furnace temperature: 1750°F/950°C.

/ Hardening: This furnace is used to improve the wear resistance and prevent deformation under the impact on gears, crankshafts, camshafts, etc. The parts may be either high carbon hardenable steels or carburized lower carbon steels. The heating chamber may be heated by either gas-fired radiant tubes or electrically heated ribbon resistors. The furnace may be equipped with an integral elevator type quench system or the work may be delivered to hand, die or press quenching. The furnace is designed for operation with non-decarburizing protective atmosphere. Maximum furnace temperature: 1750°F/950°C.

SECO/WARWICK Roller Hearth Furnace Advantages

/ Energy recuperation is easier and less costly with continuous systems

/ Continuous takes up about half of the floor space than multiple batch units

/ Longer equipment life – typically 40+ years

/ Temperature ranges from 400°F – 2250°F (200°C – 1,200°C)

/ Suitable for atmospheres from air or products of combustion to exothermic (EXOGAS™), Endothermic (ENDOGAS™), Nitrogen/Hydrogen or Ammonia (AMMOGAS™) or steam

/ Throughputs are unlimited but typically from 500 pounds (225 kg) to 15,000 pounds (6,800 kg) per hour

SECO/WARWICK Roller Hearth Furnace Processes

/ Annealing,

/ Hardening,

/ Preheat,

/ Normalizing,

/ Stress relieving.

/ Steel

/ Bearing

/ Fasteners

/ Minting

/ Defense

/ Heat recovery system,

/ During the design process, the furnace thermal accumulation aspect reducing heat losses is analyzed,

/ Reducing gas consumption and atmosphere emissions,

/ Electric heating system instead of gas,

/ Cast agitators with extended service life,

/ Possibility of cooling installed atmosphere mixers with air exchangers