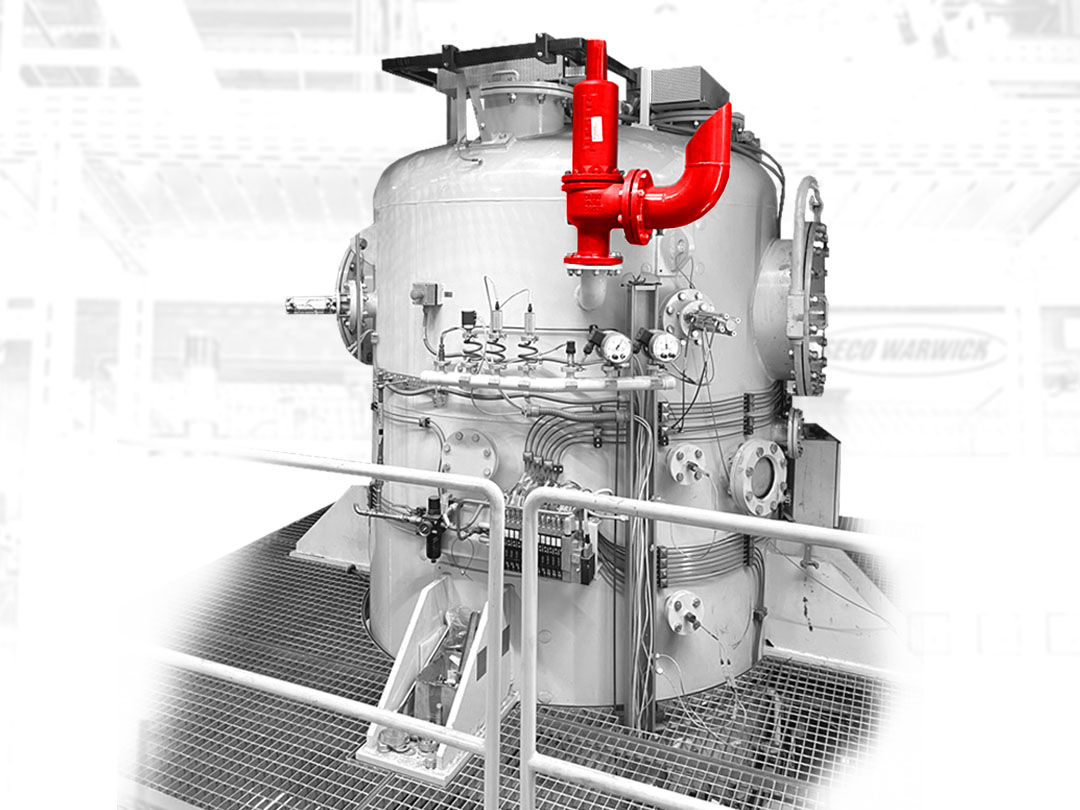

Vertical vacuum furnace

Vertical vacuum furnace 2.0VVPT-EH42/50

Working space: diameter [WxHxL] 750 x 1700 x 750 [mm]

Type of heating chamber: square, graphite

Max. gross charge weight: 1700 kg

Type of heating: graphite heating rods

Max. temperature: 1300°C

Temperature uniformity in convection gas: +/- 5°C (150°C -750°C)

Temperature uniformity in vacuum: +/- 5°C (510°C -1100°C)

Power of the heating system: 300 kW

Number of temperature zones: 1

Vacuum pumps: GXS250/2600 (1900m3/h)

Working vacuum level: <5×10-2 mbar range

Cooling blower: 37 kW

Cooling gas: Nitrogen

Temperature safety controller: 3216i

/ PERFECT SOLUTION FOR:

/ Tools

/ Oil and gas

/ Mining

/ Machine building

/ Bearing

/ Wind energy

/ Marine

ONLY ONE SUCH OFFER

ORDER NOW BEFORE SOMEONE ELSE DOES!

2.0VVPT-EH42/50

/ WHY VERTICAL VACUUM FURNACE?

/ work flexibility, resulting from the speed of heating and cooling of the load,

/ very high repeatability of processes and precise heat treatment of various parts,

/ efficient vacuum pumping system,

/ high accuracy of process control,

/ safe operation,

/ environmentally friendly

/ WHICH APLICATIONS?

/ Steel parts requiring exceptional wear resistance

/ Carburizing steels (after adjustments)

/ WHAT PROCESSES?

/ Boronizing

/ Low pressure carburizing (after adjustments)

/ Gas quenching,

/ Annealing,

/ Normalizing,

/ Solution heat treatment,

/ Degassing,

/ Brazing

/ VACUUM TECHNOLOGY – your value!

/ Short heat-up cycles,

/ Uniform process results

/ Low process gas consumption