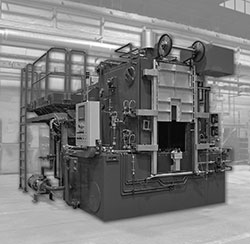

Heat Treatment Furnaces for heat treatment of metals

For over 30 years SECO/WARWICK has designed and built continuous furnaces and production lines for heat treatment of tubes for ferrous, stainless steel and alloy materials.

Heat Treatment is the controlled heating and cooling of metals to alter their physical and mechanical properties without changing the product shape. Heat treatment is sometimes done inadvertently due to manufacturing processes that either heat or cool the metal such as welding or forming.

The technology is often associated with increasing the strength of material, but it can also be used to alter certain manufacturing objectives such as improve machining, improve formability, restore ductility after a cold working operation. Thus it is a very enabling manufacturing process that can not only help other manufacturing process, but can also improve product performance by increasing strength or other desirable characteristics.

Steels are particularly suitable for heat treatment, since they respond well to heat treatment and the commercial use of steels exceeds that of any other material. Steels are heat treated for one of the following reasons:

1. Softening

2. Hardening

3. Material Modification

Process Applications

- Full annealing,

- Bright annealing,

- Solution annealing,

- Stress relieving,

- Hardening & tempering,

- Spherodize anneal,

- Tube heating,

- Hot piercing & extrusion,

- Preheating of tubes for SRMs.

Furnace and Production Line Configurations

Type of furnace design

Type of heating system

|

Adapted for operation with atmosphere

|

The SECO/WARWICK Advantage

- Custom engineered equipment to meet all ofyourunique requirements,

- Expanite® technology for surface hardening of stainless steel,

- Rolls that can operate at the temperatures of upt o 1230”C (225O”F) without a cooling water system,

- Cold testing is standard priorto shipment; hottesting is available upon request,

- Availability at level of 97%,

- Computerized Maintenance Management System (CMMS),

- Online Service,

- Heating elements thatare replaceable without interrupting the proces,

- Experience processing a wide variety of materials including carbon steel, stainless steel, lnconel, copper alloys, beryllium copper and titanium,

- Furnaces up to 108 meters (354feet) long,

- Furnaces working under protective atmospheres (hydrogen, nitrogen, argon) standard vacuum and vacuum purge options.