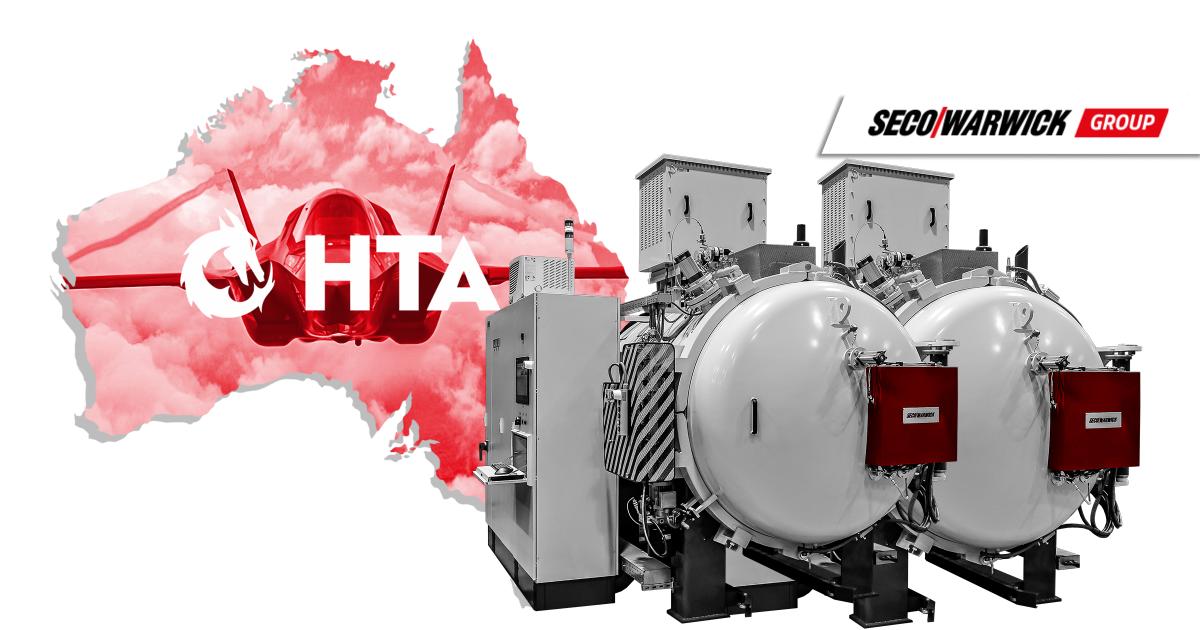

Two new Vector®- single chamber high-pressure quench vacuum furnaces from SECO/VACUUM have been purchased by HTA. Solutions go to their Melbourne and Sydney commercial heat treatment facilities to provide expanded processing capabilities to support the Australian defense industry.

The equipment will provide heat treatment processes for HTA’s manufacturing customers in the region to meet defense customer and quality specifications. The project was developed in response to customer demand and market analysis identifying gaps in Australia’s advanced manufacturing industrial framework.

Dr Karen Stanton, Director Corporate and Strategy at HTA said, “HTA is the only Australian NADCAP approved thermal processor and has had ongoing success with commercial and aerospace operations to date. Increasing the footprint of heat treatment assets through the establishment of this capability in Melbourne and Sydney will increase the ability of defense component manufacturers to deliver projects faster and allow them direct access to a qualified local supply chain.”

The partnership is one of our most important assets

“SECO/WARWICK Group has the most advanced and user-friendly vacuum furnaces on the market. But equally important to me is the way we can collaborate with their team to determine the best furnace features and capabilities to do the job. These two new Vector furnaces will be the first of their capability in Sydney and Melbourne and will be used to heat treat high strength components such as landing gear or brazing engine parts and opening up advanced processing capabilities to our new and current customers” – added Norm Tucker, Director Operations at HTA.

“HTA has been very smart about how they approach their growth, measuring business opportunities through research and thoughtfulness and looking carefully at the potential upside of their investments. We are proud to be an integral partner in their planning and execution” – concludes Piotr Zawistowski, Managing Director of SECO/VACUUM.

The Vector technology is one of the best overall solution for commercial heat treaters because of its deep process flexibility. Vector is a versatile heat treatment system that can be applied to a variety of tasks as the customer’s workloads change, from hardening for tools and dies or aircraft components, to annealing, vacuum brazing, LPC, normalizing, solution heat treating, as well as sintering and tempering.

The addition of Vector® vacuum furnaces to HTA’s processing capabilities follows 7 other installations of SECO/WARWICK products in Brisbane and Los Angeles CA, including high-pressure gas quench vacuum furnaces, vacuum aluminum brazing furnaces, and tempering/stress relieving furnaces.