Vacuum furnace for brazing vacuum interrupters

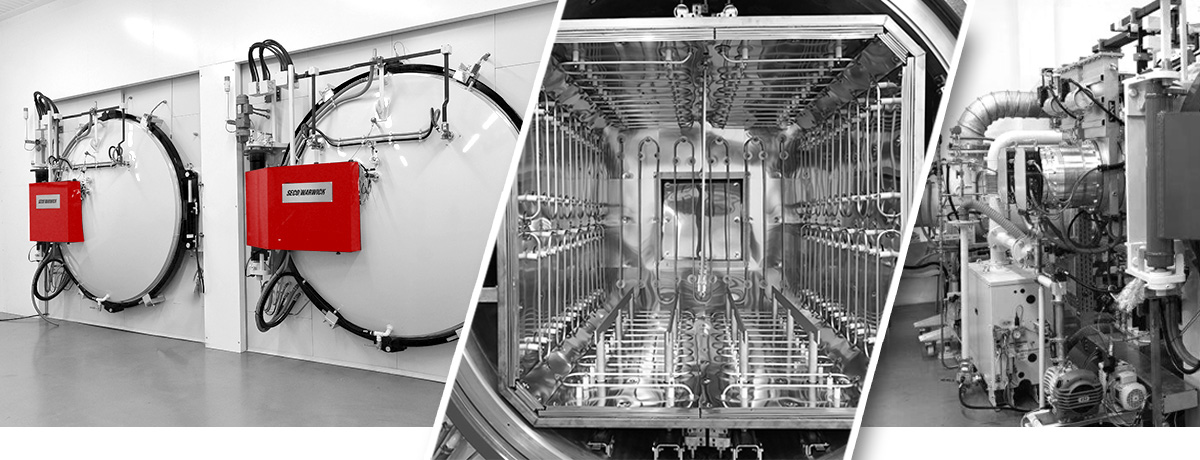

Vector UHV – vacuum furnace for brazing vacuum circuit breakers (VCB)

Vector is a single-chamber vacuum furnace that is dedicated to the vacuum brazing processing of electrical components, different switch components like vacuum interrupters, and vacuum circuit breakers (VCB).

These types of applications require a high-purity process atmosphere. Therefore, these furnaces are equipped with turbomolecular pumps to achieve high or ultra-high vacuum.

Moreover, due to the high purity requirements, the equipment is assembled and tested in a dedicated clean room in our workshop to minimize the risk of contamination inside the furnace system.

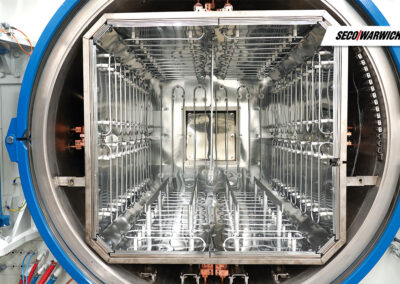

The Vector is a single-chamber horizontal vacuum furnace, equipped with a molybdenum hot zone dedicated for pure processing and turbomolecular pumps to achieve the required high–vacuum level. Additionally, the larger-sized furnace is equipped with an additional heating element to ensure optimal uniformity of all processed parts.

/ Horizontal orientation

/ Two standard sizes: 600x600x900 and 1000x1000x1200 (with an additional heating element)

/ Standard horizontal capacity 600kg and up to 1500kg

/ Metal hot zone

/ Six control zones controlled by thyristors

/ Ultra-high vacuum thanks to using turbomolecular pumps

/ External gas quenching system

/ Quenching pressure: 1 bar abs.

/ Quenching gases: N2, Ar

/ A computer control system, operator-friendly

/ Temperature uniformity: ± 3oC

/ Ultimate vacuum: ≤8×10-8 mbar

/ Operating vacuum: at temp. 850oC: 1×10-6 mbar

/ Leak rate: range 1×10-4 mbar l/s

/ Brazing

/ Electrical

/ Energy

/ Power

Two sizes:

/ 600x600x900mm with load weight 200kg without an additional heating element

/ 1000x1000x1200 with load weight 1200kg or 1500kg with an additional heating element (2x500mmx1000mmx1200mm)

/ Other sizes on request

/ Vacuum as a protective and technological atmosphere eliminates the need to use harmful process gases and their emission to the environment

/ No CO₂ emissions, no use of fossil fuels

/ Gas utilization for cooling (nitrogen, argon), captured and returned to the air, neutral for the environment

/ Reinforced thermal insulation saves electricity (approx. 20%)

/ High energy efficiency of used electrical components (IE3 class motors, inverter control, etc.)

/ Application of systems and algorithms limiting energy and technological factor consumption (pumping, heating and cooling systems)

/ No harmful substance emissions

/ Reduction of hardening deformations and downstream machining costs

/ Elimination of part washing after heat treatment