SECO/WARWICK will deliver the third Solution Heat Treatment line for a key Indian manufacturer in the defense and aviation sector – Tata Advanced Systems Limited (TASL). This order will be the largest production line for aircraft skins in the history of both companies.

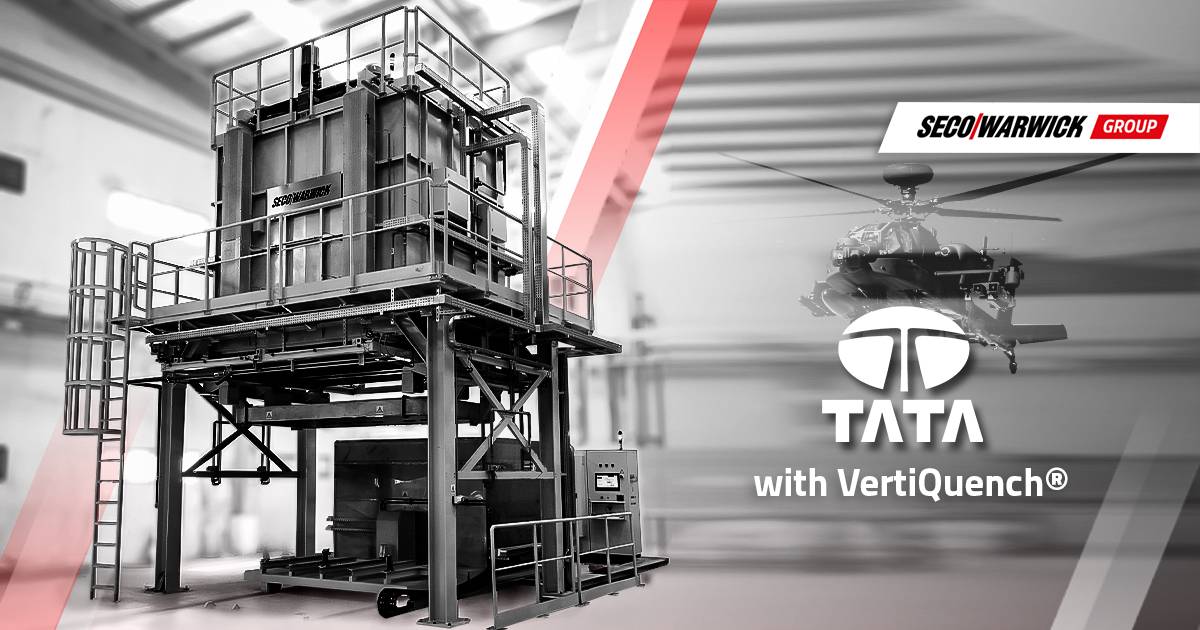

The equipment that SECO/WARWICK will build for TASL is a production line for the Solution Heat Treatment of aluminum alloys. It is dedicated to the aviation industry and will meet the stringent requirements of the latest aviation (AMS2750F) and material (AMS2770) standards. The SECO/WARWICK equipment will be used for the production of aircraft skins, empennage and center-wings boxes. The line includes a rapid quench VertiQuench® electric furnace (drop-bottom type), mobile quenching tank, rinsing tank and additional equipment including a chiller and loading baskets.

The working zone of the furnace is L7500xW3000xH3000mm, with the capacity to process huge sheets of aluminum. This is a big advantage in manufacturing these aircraft skins. Such a large working zone reduces the number of joints in the skin. The line, as designed, will meet the client’s requirements, ensuring a guaranteed +/- 5°C load temperature uniformity, load cooling in either a polymer or a water quench, and will remove the polymer sediment remaining after quench. Additionally, the system can be used for artificial aging in the furnace.

VertiQuench® Solution Heat Treatment furnace – designed for aviation

The huge working zone of the furnace is only one feature that makes this system ideally suited to the aviation industry. Apart from the size of the working zone, a very important parameter is the speed of full immersion of the load in the quench tank. In this configuration and thanks to the advanced hoist and door opening systems, the rapid quench time is as short as 5 seconds. As a result, we obtain a final product that meets the material and aviation heat treatment standards for very demanding types of alloys. This means that the new line will reduce the cycle time and the number of Solution Heat Treatment process steps required to meet TASL plant capacity requirements. Thus, the SECO/WARWICK line will reduce operating costs and eliminate some additional joints in the aircraft skins.

„The challenge for our R&D Department was to meet the individual requirements of TATA Advanced Systems Limited. To obtain the required speed of immersion of the load as short as 5 seconds, for this size basket we have used an advanced elevator drive and door opening systems. As a result, our Solution Heat Treatment line meets the requirements of the latest aviation standards,” explains Piotr Skarbiński, Vice President of the Aluminum Process and CAB Business Segments at the SECO/WARWICK Group. “We are very proud that we were chosen for the third time by TASL, key supplier to leading aircraft manufacturers. The previous two Solution Heat Treatment lines were delivered to Nagpur and Hyderabad plants in India. For us, this continued cooperation directly means that the client is satisfied with the quality and efficiency of SECO/WARWICK’s equipment, services and our partnership. We hope that this partnership will continue into the future,” concludes P. Skarbiński.

Aluminum processing is SECO/WARWICK’s specialty

SECO/WARWICK was selected as the supplier of the new Solution Heat Treatment line in recognition of the company’s ongoing technological advancement, an individual approach to each project, as well as client satisfaction and experience.

„We appreciate the cooperation with SECO/WARWICK because of the professional service that is provided to us in the field for the two previously delivered heat treatment lines. Therefore, SECO/WARWICK was the company of first choice for this order. The new line, apart from its size, will meet a number of guidelines that will allow us to produce the highest quality airplane components that will meet the expectations of our final customers – a vast portfolio of OEMs and Tier-1s in the aerospace & defence industry. We are also confident that SECO/WARWICK will be able to meet the Project timelines and handover the line well within our project timelines” concludes Abhishek Paul, Manager and Head – Supply Chain Management of TATA Advanced Systems Limited.

TATA Advanced Systems Limited is part of the TATA group responsible for the aviation industry. With over 5,000 employees, it is a global component supplier, chosen by the world’s leading aerospace and defense manufacturers.