Vacuum hardening with Distortion Control as A Modern Alternative to Press Quenching – 4D QUENCH®

A vacuum system for single-piece nitrogen quenching with distortion control as an attractive alternative to a press quenching

4D Quench® – is a vacuum heat treatment system solution for individual quenching of component parts such as gears, shafts, bearing races, rings, selves, etc. made of standard or custom case and through hardening steels. The system operates under nitrogen. It provides excellent distortion control and notably increases precision and repeatability of heat treatment while reducing unit and overall production costs.

/ It notably increases precision and repeatability of heat treatment results and reduces production costs

/ It provides vacuum heating following by powerful and uniform nitrogen quenching resulting in distortion control & reduction with high repeatability of final results.

/ The system is fully automated and easily integrated with in-line production.

/ It’s a modern and attractive alternative to hardening in a press, eliminating all its disadvantages.

4D Quench® is dedicated to these who wants to significantly increase production quality and economy of mechanical transmission components compared to batches or continuous heat treatment systems as well as to eliminate press quenching, press hardening, and their disadvantages..

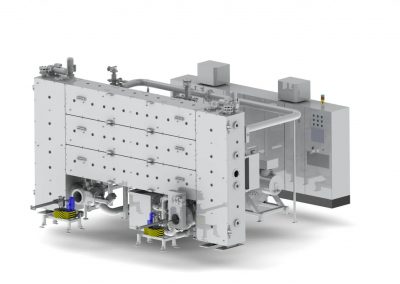

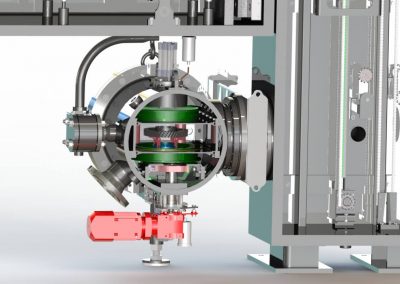

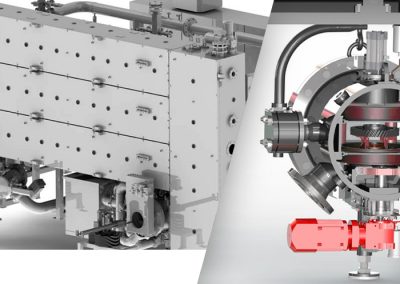

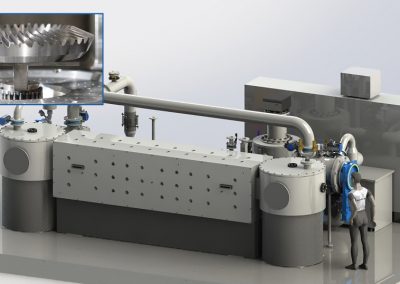

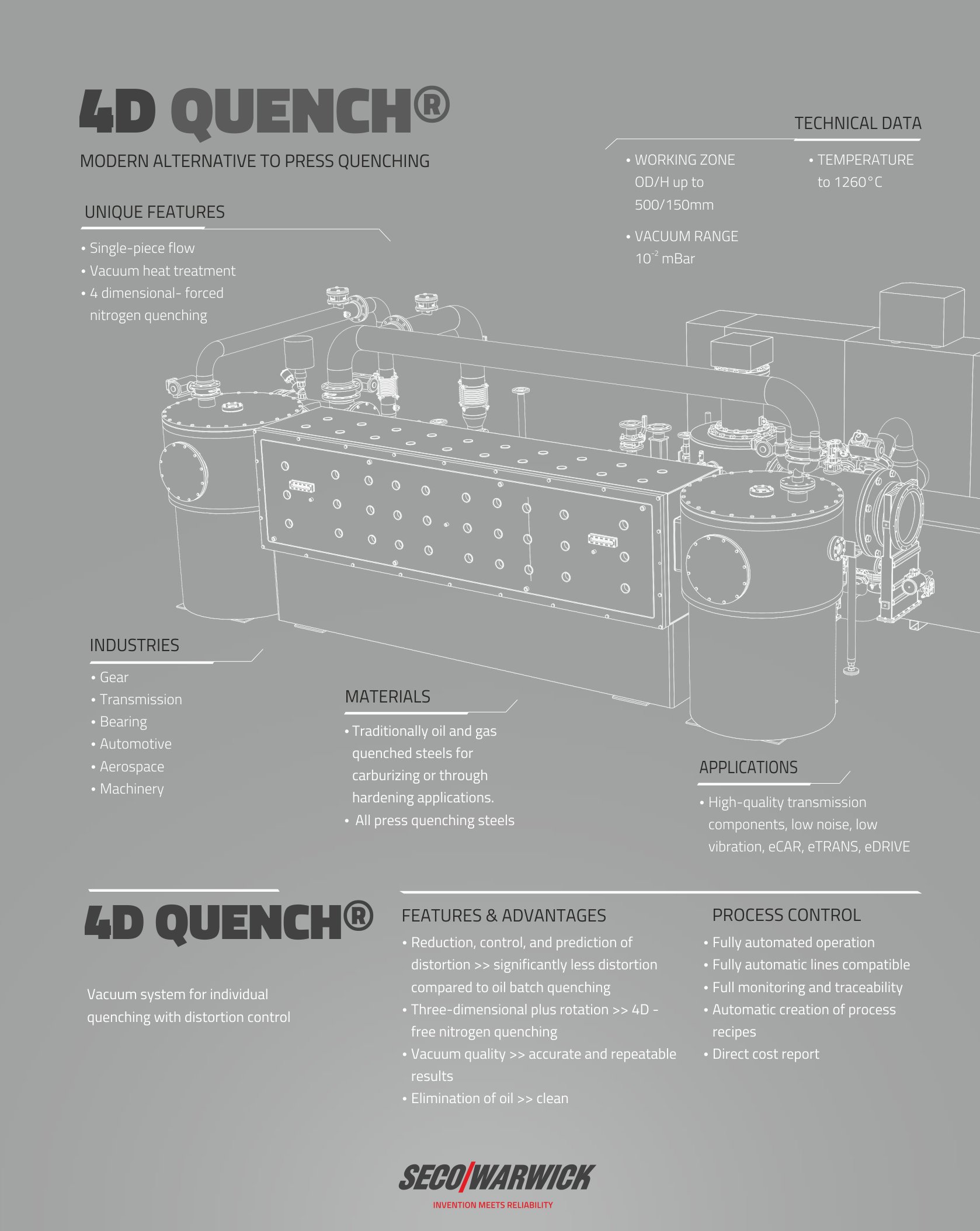

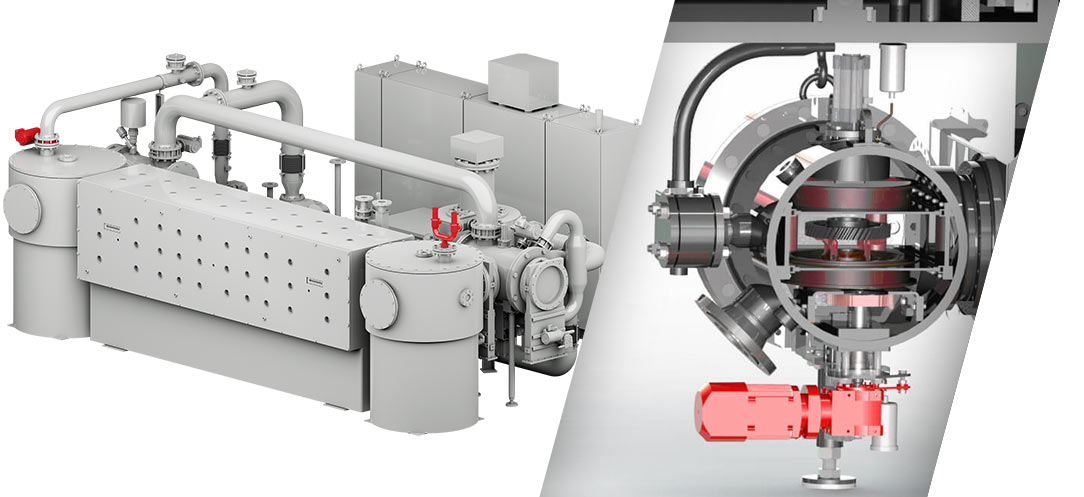

The system consists of a vacuum heating chamber and a high pressure nitrogen quench chamber equipped with transportation mechanisms. Parts are heated up to hardening temperature in the heating chamber under vacuum, which protects the part’s surface against oxidation or other unwanted metallurgical changes. The quenching process provides unique and significant improvements related to the reduction of distortion. This is done primarily using a high-pressure gas quenching system installed in the quenching/unloading chamber. The system utilizes a proprietary arrangement of cooling nozzles that surround the part to ensures a uniform flow of cooling gas ffrom all sizes, as well as the top and bottom. We refer to this as “3D” cooling. In addition, a table spins the part, further enhancing quench uniformity. We refer to the spinning motion adequately as the fourth dimension, allowing us to “4D” quench parts for the best possible uniformity. The cooling nozzles pattern can be adequately adjusted to fit the particular parts size and shape. The entire nitrogen cooling system rovides the equivalent of an oil quench with more uniform cooling, which results in absolute repeatability, reduces distortion and allows for highly repeatable results. Oil or specialized gases such as helium are not required. Neither oil nor helium is needed anymore.

The single piece-flow method, while parts are passing through heat treatment one by one, enables full integration into manufacturing cells and in-line production, alongside of CNC machines. It eliminates heat treatment fixtures, material logistic cost and time as well as shortens production cycle. Moreover, repeatability of quenching results and distortion control and reduction provides great potential for reduction of hard machining costs.

In addition, every single part is monitored and reported during heat treated, which provides 100 % traceability and quality control. The system and applied technology is safe, clean and environmentally friendly.

/ Integration into manufacturing cells and in-line production

/ Up to 1 mln pieces/year.

/ The adaptable working zone size.

/ Customize system configuration.

/ Compact design, low footprint.

/ Low utility consumption.

/ 4D Queching with adjustable quench nozzles.

/ High pressure nitrogen quench.

/ Absolute precision and repeatability of results.

/ Elimination of IGO/IGA.

/ No oxidation/ no air present.

/ Optimum part’s Surface.

/ High volume production.

/ Operational flexibility, on demand start/stop.

/ Fully automated, avoiding operator induced variability or errors.

/ 100 % traceability and examination of every part.

/ No man involvement and impact.

/ Nitrogen quench as fast as oil (neither oil nor helium is needed).

/ Elimination of heat treatment fixtures and material logistic.

/ Elimination of oil and oil vapor contamination (safety and environmental benefits).

/ Elimination of washers and chemicals.

/ Elimination of high-temperature radiation and fire risk.

/ Safe and environmentally friendly technology.

/ Elimination of copper masking or stop-off paints.

/ Transmission,

/ Bearing,

/ Machinery,

/ Aerospace.

/ Higher alloy and special steels for gas and oil quenching.

/ many times less hard machining time,

/ elimination of many post-machining operations,

/ low pressure carburizing / high pressure gas quench,

/ fast and efficient carburizing,

/ elimination of fire and explosion hazard,

/ ideal surface quality,

/ elimination of IGO,

/ clean and enviromentally friendly production.