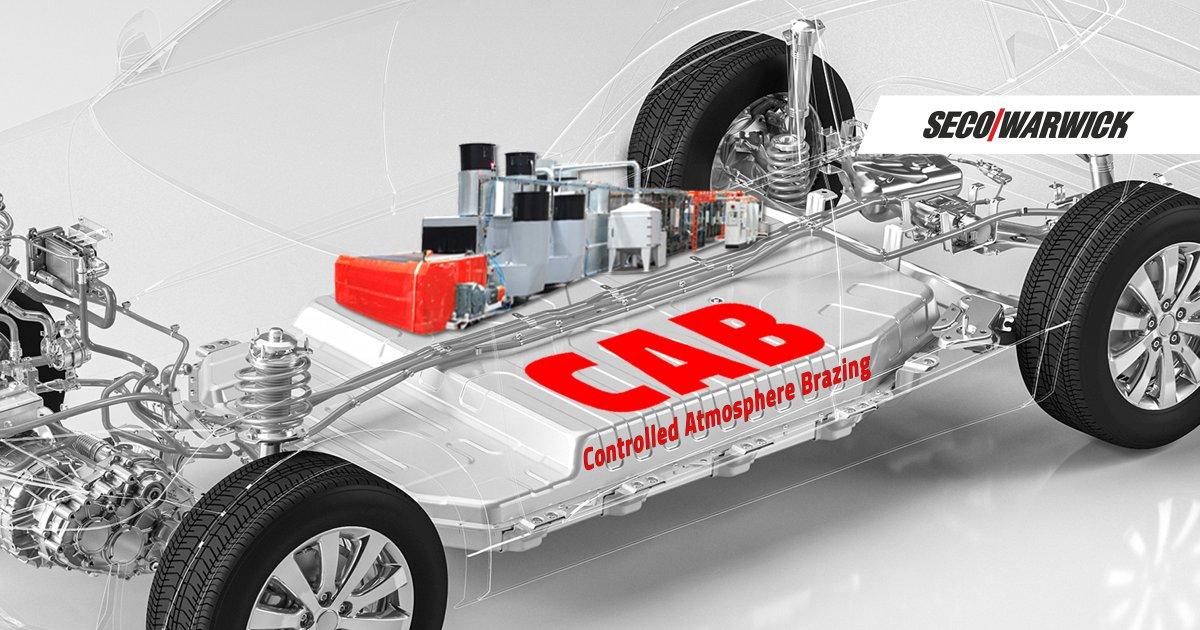

SECO/WARWICK, global leader of CAB technologies, has signed a contract for a delivery of the widest production line in history. The Continuous Line for Controlled Atmosphere Brazing of large-dimensions battery coolers will be installed at the plant of one of the leading European manufacturers of heat exchangers. This is a second order placed by the customer for the same product within the last two years.

European mass production of vehicle battery coolers

For another year in the row, Europe records the highest global sales of electric vehicles. The Old Continent becomes a serious player in the global race for the new industry and attempts to build a supply chain of batteries and other necessary parts of electric vehicles from scratch. In 2020, the sales of battery electric vehicles constituted 5.4% of the sales in the European Union. If the current trend continues then, according to the EU emissions reduction strategy, the share will increase to 21% in 2025 and to 54% in 2030.[1] The dynamic growth of battery sales involves the growth of sales of other parts such as battery coolers. They are manufactured using highly-specialized continuous lines for controlled atmosphere brazing.

“We observe a very dynamic growth in the demand for CAB lines that are used for the production of heat exchangers. The trend associated with e-mobility is very strong. Globally, we sell more and more CAB lines, which prove well in this industry. Our equipment is operated not only in Europe, but also in Asia and North America. We have been perfecting this product for several years and now I can say that, in my belief, there is no other more comprehensive, reliable and efficient aluminum brazing line available on the market. Our latest contract supports it. This time it will be the widest CAB line in history. And I am truly convinced that it will have a significant impact on increasing the number of battery coolers manufactured in Europe” — said Piotr Skarbiński, Vice-President, Business Segment Aluminum Process and CAB, SECO/WARWICK.

A second order for a CAB line in two years

After years of commissioning non-European manufacturers with the production of batteries and coolers for electric vehicles, Europe truly gets in the game. The current order from the European manufacturer is already the second contract concluded with SECO/WARWICK in the last two years. The previous one also covered a delivery of a CAB line. Two years of operations have proved high performance, efficiency and reliability of the equipment. This led to the current order which will be a special one for SECO/WARWICK, also because it will be widest CAB line in the company’s history. Its usable dimensions will allow the customer to manufacture large-dimensioned vehicle battery coolers at a mass scale.

“This order proves the leading position of SECO/WARWICK in terms of delivery of CAB equipment intended for, among others, production of vehicle battery coolers. Often customers contact us again after some time and decide to continue the development of their machinery base with us. This time we should emphasize that the gap between the orders was relatively short. This testifies to the high quality and performance of our products. We are glad that our partners are not only satisfied with the equipment itself but also with the entire project implementation process” — P. Skarbiński emphasized.

[1] UE emissions reduction strategy (i.e. European Green Deal) https://ec.europa.eu/clima/policies/eu-climate-action_pl