Aluminum Furnaces for Heat Treatment

Aluminum Heat Treatment Systems

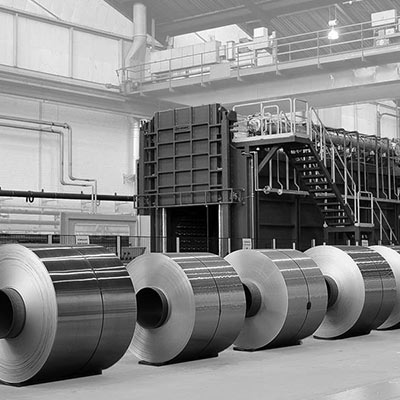

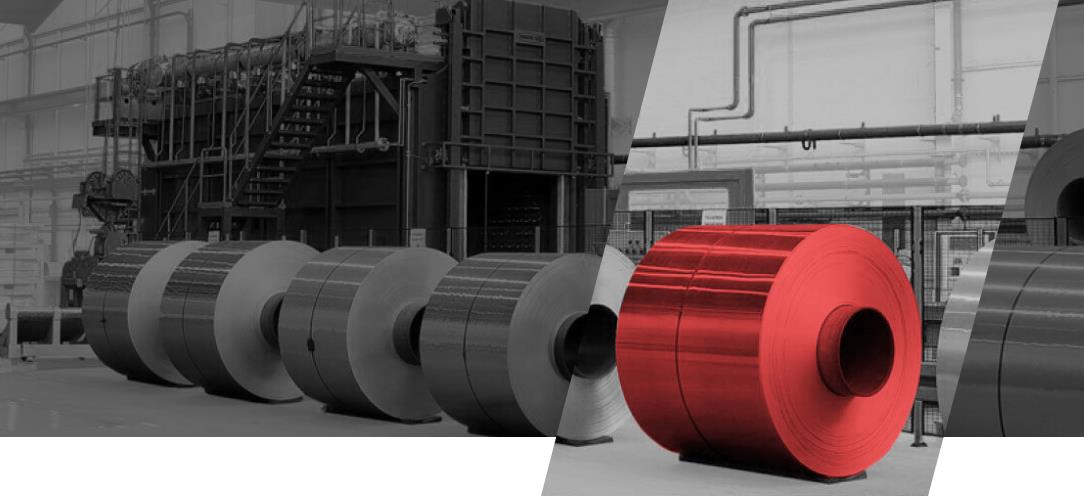

SECO/WARWICK provides basic product groups including coil/foil annealing, solution heat treatment & aging, homogenizing, ingot heating, and melting & holding furnace systems.

We offer advanced technology to reduce cycle times, conserve energy and improve cooling rates. Our control and material handling systems are designed for each unique production environment. With our experience, we are the single source for all your aluminum process furnace system needs and we guarantee the performance of our equipment.

-

Vortex®

Aluminum Coil and Foil Annealing FurnacesAluminum Coil and Foil Annealing Furnaces

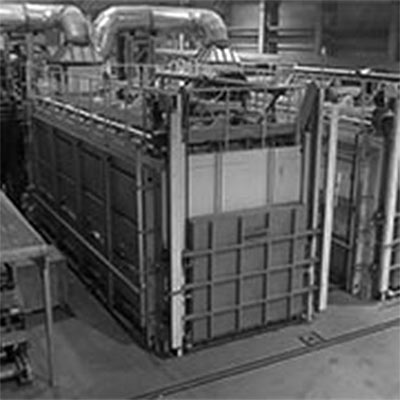

VertiQuench® Solution HT and Aging Drop Bottom Type FurnacesAluminum Age

and AnnealingMelting and Holding FurnacesOur systems operate in more than 30 countries around the world for primary and secondary aluminum production as well as for further processes with the aluminum furnaces that allow the delivery of semi-finished and finished products.

-

Continuous Aluminum Solution FurnacesVOC Thermal oxidizerAluminum HomogenizingAftermarket for Aluminum Process Furnaces

/ Aluminum Technologies:

brazing, annealing, solution, aging, homogenizing, preheating, melting./ Industries:

automotive, engineering, energy, aerospace, marine, chemical, defense, electronics./ Essential features:

Specialized aluminum brazing built to individual requirements. Customization of processes to the specificity of the batch, performance and quality requirements. Process time reduction, energy and other energy factors consumption minimization, meeting customer-specified standards, such as aviation, automotive, environmental and other. Dedicated peripherals: load transport, interoperation cleaning, flux application, packaging, harmful substances emissions reduction./ Systems:

Vortex® – patented nozzle heating technology.

SeCoil® – expert system for the design, simulation, optimization and control of the heating processes of aluminum coils.

VertiQuench® – Drop bottom furnaces equipped with quench tank for the aerospace and automotive industries. Quench tank could be filled-up by water or polymer quenching media.