Batch furnace for brazing aluminum

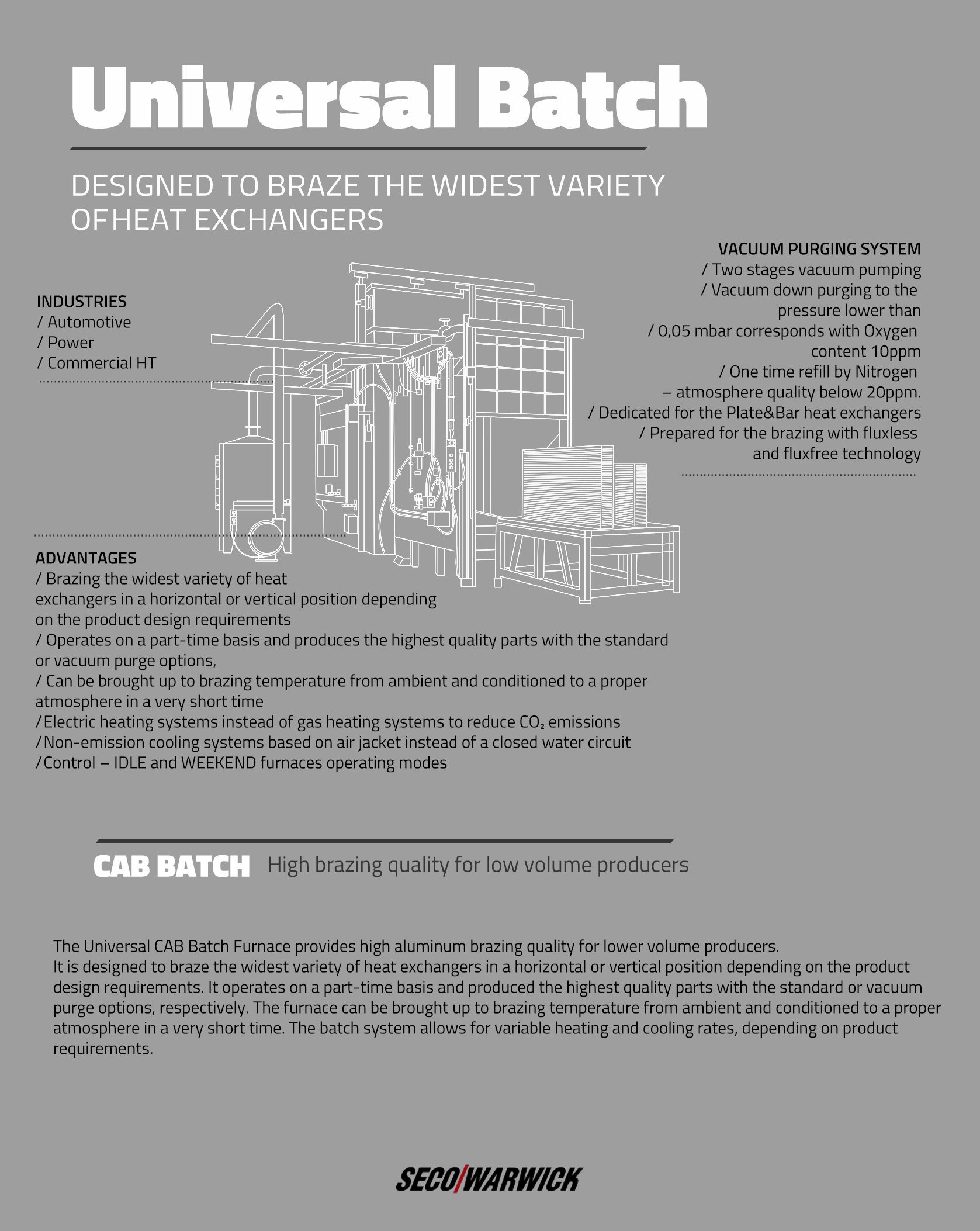

The Universal CAB Batch Furnace provides high aluminum brazing quality for lower volume producers. It is designed to braze the widest variety of heat exchangers in a horizontal or vertical position depending on the product design requirements. It operates on a part-time basis and produced the highest quality parts with the standard or vacuum purge options, respectively. The furnace can be brought up to brazing temperature from ambient and conditioned to a proper atmosphere in a very short time. The batch system allows for variable heating and cooling rates, depending on product requirements.

in part types and brazing position: horizontal or vertical

/ Short preparation time

with only 2-3 hours required

/ High brazing quality

using a clean nitrogen atmosphere, high-temperature uniformity, and sharp heating profiles

/ Fits into tight locations

due to a compact design

/ Lower cost

for investment, installation, and operation

Additional benefits of Vacuum Purging option:

/ Significantly lower nitrogen consumption

than other batch units

/ More shiny silver surface after brazing

results comparable with vacuum brazing

/ Higher brazing quality of products

due to perfect purging and nitrogen refilling with internal closed volumes of the cores.

with Vacuum Purging

Single chamber furnaces with vacuum purging are also available for special applications, mostly dedicated for R&D laboratories, prototyping, and any initial low volume production. This special design enables precise control of the heating and cooling speeds during the entire cycle. Atmosphere conditions like oxygen and/or dewpoint can be set on the defined level. This batch-type furnace allows the user to simulate a wide range of brazing conditions and brazing process profiles that would be experienced in a continuous furnace.

This furnace has a compact design with an internal recirculation fan and external cooling air blower. The packaged furnace system consists of the heating system, vacuum pumping system, nitrogen system, and atmosphere controls. The brazing cycle begins with vacuum purging of the stainless steel retort with N2 back purge, followed by fast and uniform heating up to brazing temperature. When the soak cycle is complete, the cooling cycle is initiated.

The advantage of a vacuum purge batch furnace is that it is always ready for work at room temperature and it is cold when the cycle is completed. No preparation pre-heating is required.

/ Thermal afterburner to reduce VOC emissions for degreasers,

/ Scrubber with active aluminum oxide deposit to reduce the emission of hydrogen fluoride generated during brazing process,

/ For gas-heated solutions, energy recovery systems reducing gas consumption and thus CO2 emissions:

- energy exchange system between the thermal afterburner and degreasers,

- energy recovery from the preheat chambers and brazing furnace by transferring exhaust gases under the inlet tunnel and further as support for the Dryer heating system.

/ Electric heating systems instead of gas heating systems (including modification of current equipment) to reduce CO2 emissions.

/ Optional applications of high-performance microporous insulation to reduce heat losses and thus reduce energy consumption (in case of gas heating systems – reduction of CO2 emissions).

/ Heated curtains inlet tunnel to limit the conveyor belt and load temperature drop during the transfer, and thus shortening the reheating time – in the overall balance, lowering energy consumption (in case of gas heating systems – reduction of CO2 emissions).

/ A common conveyor belt for the dryer (or TTBB) and the furnace to reduce the energy consumption associated with double heating in case of separate systems (in case of gas heating systems – reduction of CO2 emissions).

/ The customer uses energy emitted by the cooling chambers’ and the dryer’s extraction systems to support the plant installations’ heating.

/ Non-emission cooling systems based on air jacket instead of a closed water circuit.

/ Control – IDLE and WEEKEND furnaces operating modes lowering the operating temperature and turning the furnace off when it is not needed during production breaks – lowering energy consumption (in case of gas heating systems – reducing CO2 emissions).

DOWNLOAD

Universal CAB Batch Furnace – brochure

Allowing a large variety of different heat exchanger types and sizes to be brazed

Vacuum purging: progressive innovation for CAB equipment & processes – brochure

By adapting the vacuum purging operation in the CAB process, the brazing quality may be significantly improved as well as reducing operational utility costs

Spare Parts & CAB Line Modifications