SECO/WARWICK is the leader in metal heat treatment. To be there, you need to create and implement technology that breaks the rules.

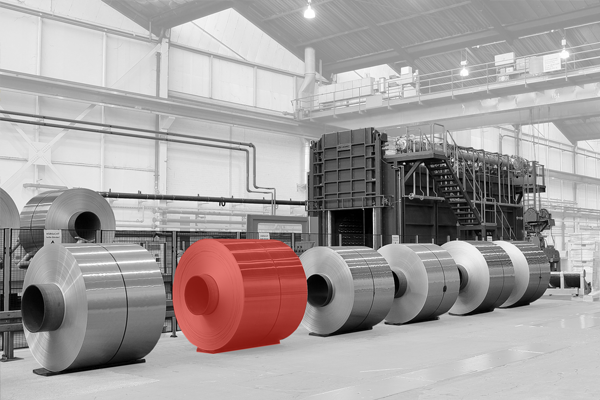

Pit-LPC

Vortex® Jet AirFlow

Using patented Vortex jet airflow technology, SECO/WARWICK’s Vortex® aluminum coils annealing system, combined with optional Bypass Cooler and SeCoil® control and simulation software, provides coils producers the ability to significantly reduce the overall cycle time of their furnaces, resulting in energy savings, increased productivity, and improved surface quality.

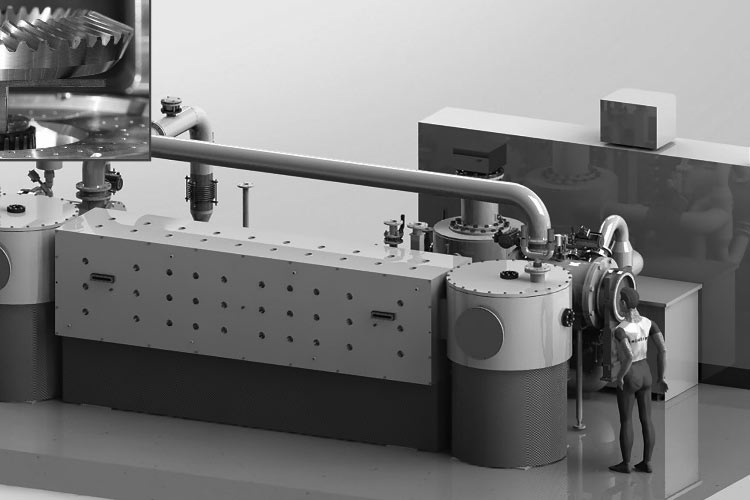

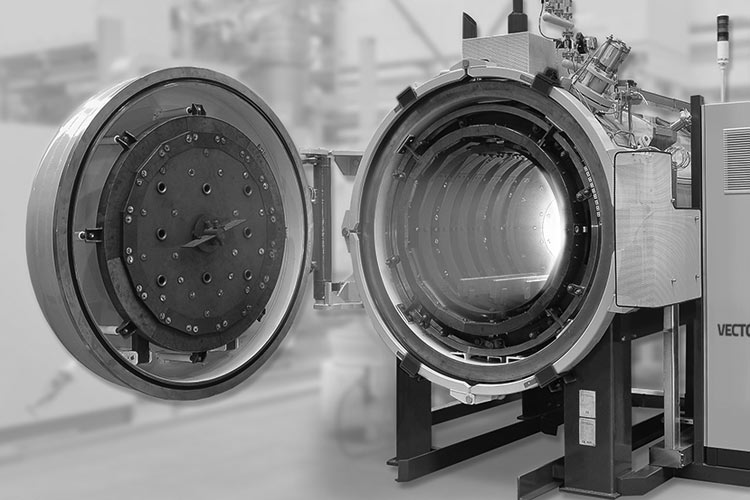

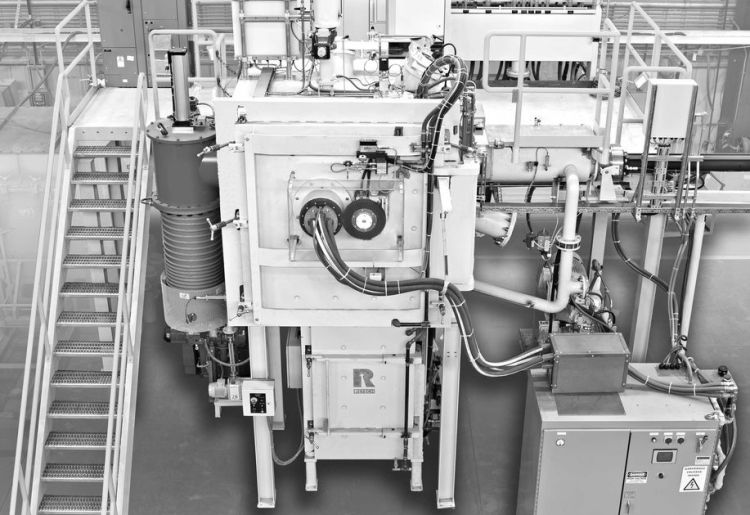

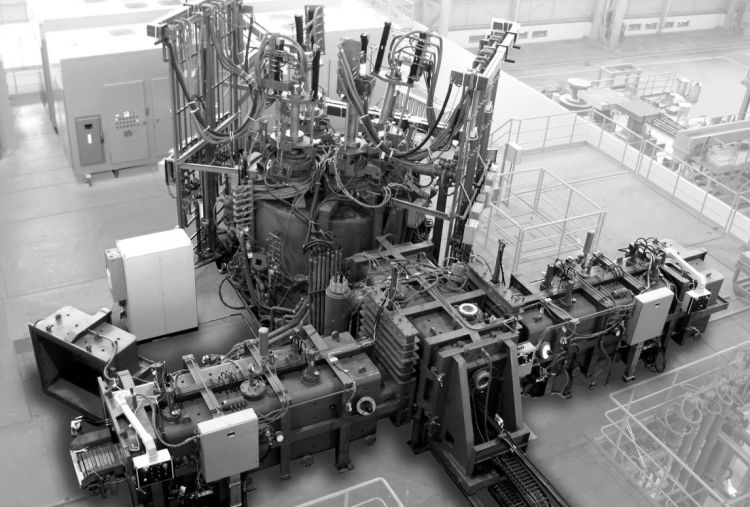

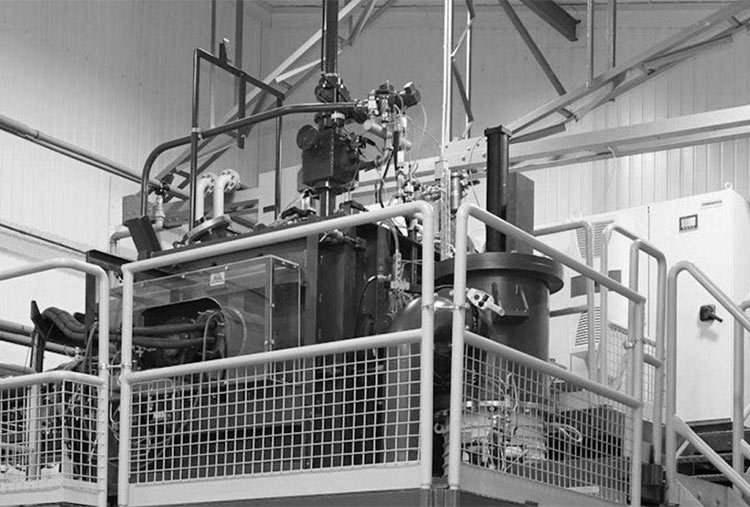

VIM Vacuum Induction Melting

PAM Plasma Arc Melting

JetCaster

Vacuum melting furnace VIM is used for production of high quality precision castings, which are mostly made from super alloys of blades of power and aviation turbines. Our designs and high quality of workmanship guarantee safety and ergonomics of operators’ work, reliability and continuity of production and easy maintenance of equipment.