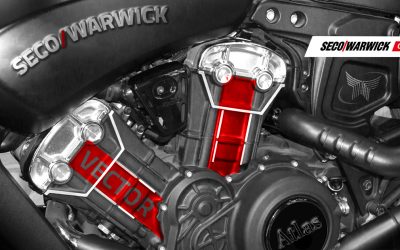

SECO/WARWICK furnace to produce specialized dies for motorcycle parts

SECO/WARWICK will supply a Vector® vacuum furnace to Atlas Autos Ltd, (An Atlas Group Company), the largest manufacturer of motorcycle parts in Pakistan. The solution is intended for hardening and tempering processes, and its design will allow for gas cooling…

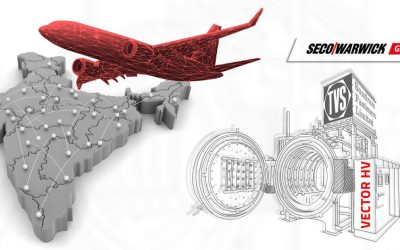

Vector, aviation industry, India: SECO/WARWICK’s common denominator

Sundram Fasteners Limited is the Indian fastener manufacturer where SECO/WARWICK will provide a VECTOR® vacuum furnace to be a part of the highest quality aviation screw production process. This is the second time both companies have cooperated. The partner already…

SECO/WARWICK INDIA Celebrates Their Five Year Anniversary

For the Indian subsidiary of the SECO/WARWICK® Group, May 2022 marks the fifth anniversary of its establishment. During that time, the company received several dozen orders for metal heat treatment equipment, placed by the leading companies on the Asian market.Regular…

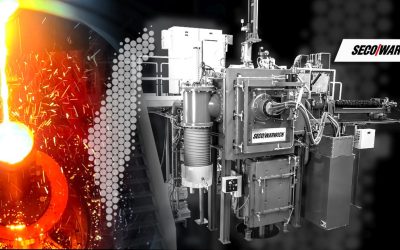

The first vacuum furnace for titanium casting for delivery to Israel

Rafael Advanced Defense Systems, an Israeli pioneer in defense and cybernetic solutions, has purchased a vacuum titanium casting furnace from SECO/WARWICK for UPC Precision Castings. This is the first furnace of this type on the Israeli market. Highest quality titanium…

Global Automotive Components Manufacturer Orders Vacuum Furnace to Increase Production

SECO/VACUUM, a SECO/WARWICK Group company, has received an order for a 2-bar Vector® vacuum heat treating furnace from an OEM who had recently ordered 6 new tempering furnaces for its machine tool manufacturing facility. The international buyer’s automotive division…

Superior support wins order for new Vector® vacuum furnace from SECO/VACUUM

American manufacturer of automotive metal seals will be replacing an existing vacuum furnace to meet high performance standards. SECO/VACUUM, a SECO/WARWICK Group company, will deliver Vector high-pressure gas quench furnace (HPGQ) to replace an existing furnace that failed to deliver…

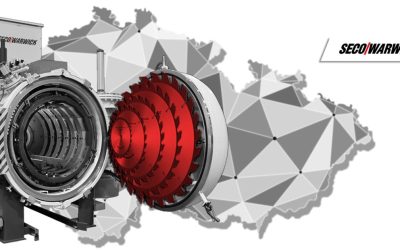

SECO/WARWICK furnace customized for Czech knives

A renowned Czech manufacturer of machining tools, industrial knives, mulching knives, and chippers – Pilana Group – has placed an order with SECO/WARWICK for a Vector® vacuum furnace with 10 bar high-pressure gas quenching. This is one of the Group’s…

SECO/WARWICK furnace speeds up screw production

Solvera Gawel Technology S.A., the supplier of fasteners, chose SECO/WARWICK as their vacuum furnace supplier. The equipment on order is a Vector® vacuum furnace because the partner’s previous experience with SECO/WARWICK’s solutions was with atmospheric furnaces. The new furnace will…

An unparalleled SECO/WARWICK furnace for a Chinese manufacturer of aerospace components

A Chinese manufacturer of aerospace components is a customer that has placed their trust in SECO/WARWICK for the fifth time, ordering advanced technology for metal heat treatment. This recent order is for a Vector vacuum furnace featuring a molybdenum chamber…

Global leader of the bearing industry selects a SECO/WARWICK vacuum furnace

Global bearing manufacturer, has decided to furnish one of its Chinese plants with a vacuum furnace by SECO/WARWICK with gas quenching, carburizing (LPC) and carbonitriding (LPCN)