SECO/WARWICK will provide the global bolt manufacturer — Solvera Gawel Technology S.A. — with a second ATE process line comprising an electrical mesh belt PTE furnace.

The new line will be intended mostly for carbonitriding and hardening processes (under endothermic atmosphere enriched with methane and ammonia) and for washing and tempering of high-quality screws and other hardware manufactured near Rzeszów.

The Electrical Belt Conveyor Unit (ATE) under the contract will already be the second, twin, process line in the Solvera Gawel Technology S.A (SGT) plant. The first, virtually identical one, has been delivered by SECO/WARWICK in 2017. Dynamic growth of the company and the pursuit of expansion on the Western markets made SGT to opt for expanding their machinery park.

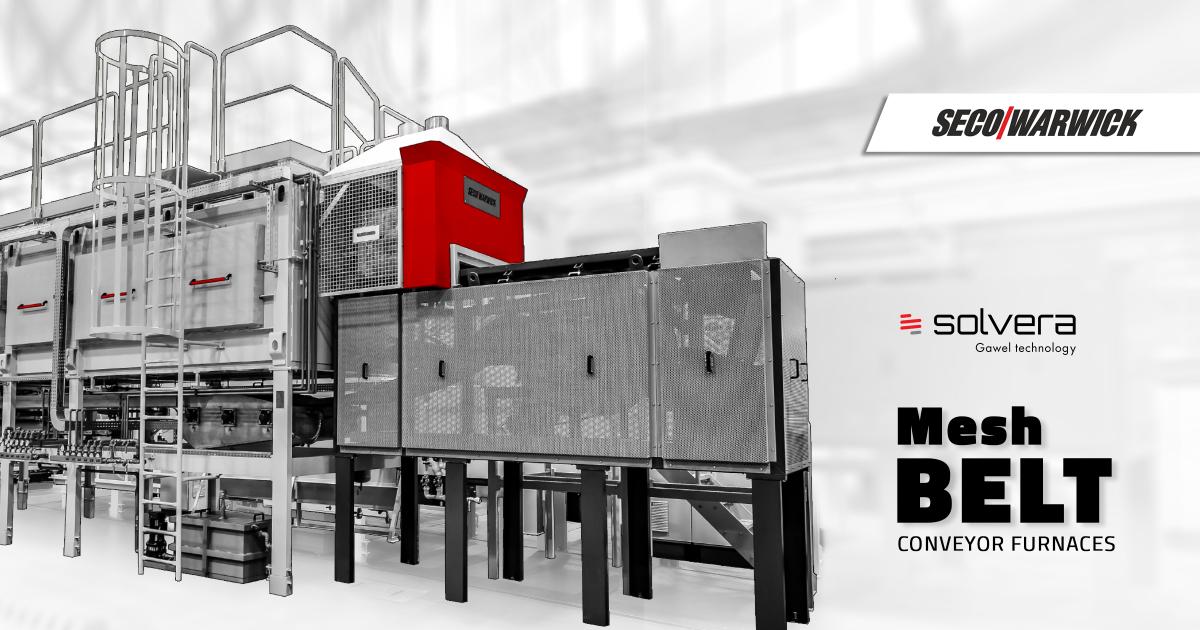

ATE process line — a leading solution for mass production

An electrical belt conveyor unit is a device that is well-suited for the manufacture of, for example, small hardware that requires perfect repeatability. Therefore, this solution is most often selected by manufacturers of bolts and hardware and commercial hardening plants. Similar solutions by SECO/WARWICK have already been delivered to Germany, Russia and Czechia, as well as to India and the United States.

“ATE process line is our proprietary and proved design which we have been refining for years to create, in my opinion, one of the most robust devices of this kind on the market. It enables maintaining the assumed process parameters of the heat and chemical treatment in a stable manner while ensuring the high reliability of the equipment. An electric mesh belt furnace (PTE) is particularly well suited for continuous operation in the production lines. Since the furnace can be used in a multitude of processes, it is well recognized by global hardware manufacturers. It is also used in the production of parts wherever the precise serial production is necessary, including for example the automotive industry” — said Piotr Skarbiński, Vice-President, Business Segment Aluminum Process and CAB, SECO/WARWICK. “I am very glad about the very dynamic growth of Solvera Gawel Technology and that the company again selected SECO/WARWICK. This is a huge token of trust for us as well as a proof that our equipment, work and services meet the expectations of our partner” — P. Skarbiński added.

The ATE process line which will be delivered in 2022 to the Solvera Gawel Technology S.A. plant will be adapted for operating with endothermic atmosphere supplied from an external endothermic generator.

It will consist of a loading module equipped with a weighing system, main furnace (enabling carburizing and carbonitriding process), oil bath (for hardening the workpieces), vibration and reloading tables. After the hardening process, the workpieces are transferred to a drum washer where they are washed, rinsed and finally dried. Hardware so prepared is transferred to a high tempering furnace, and then to the passivation bath. The line is completed with an arrangement of control cabinets with the SECO/SCADA master system.

Hardware manufacturers require repeatability

SOLVERA GAWEŁ TECHNOLOGY S.A. (SGT) is a renowned manufacturer of hardware items such as wood, metal and plastic screws. Over the years, the company has launched many innovative products.

“From the very beginning of our operations, we have paid a lot of attention to the high production quality that is possible thanks to ensuring repeatability. Five years ago, the SECO/WARWICK ATE line has won us with an innovative design that perfectly matches our production needs. We have very ambitious growth plans. A few years back, we have established branches in America and Asia” — said Tomasz Gaweł, President of the Management Board of Solvera Gawel Technology S.A. “Process solutions provided by our partner enable the production of materials with the highest quality. Together with SECO/WARWICK we have a similar operating philosophy, and thus our cooperation is so good” — T. Gaweł added.

The ATE line will be commissioned in the Solvera Gawel Technology S.A. plant in the second quarter of 2022.