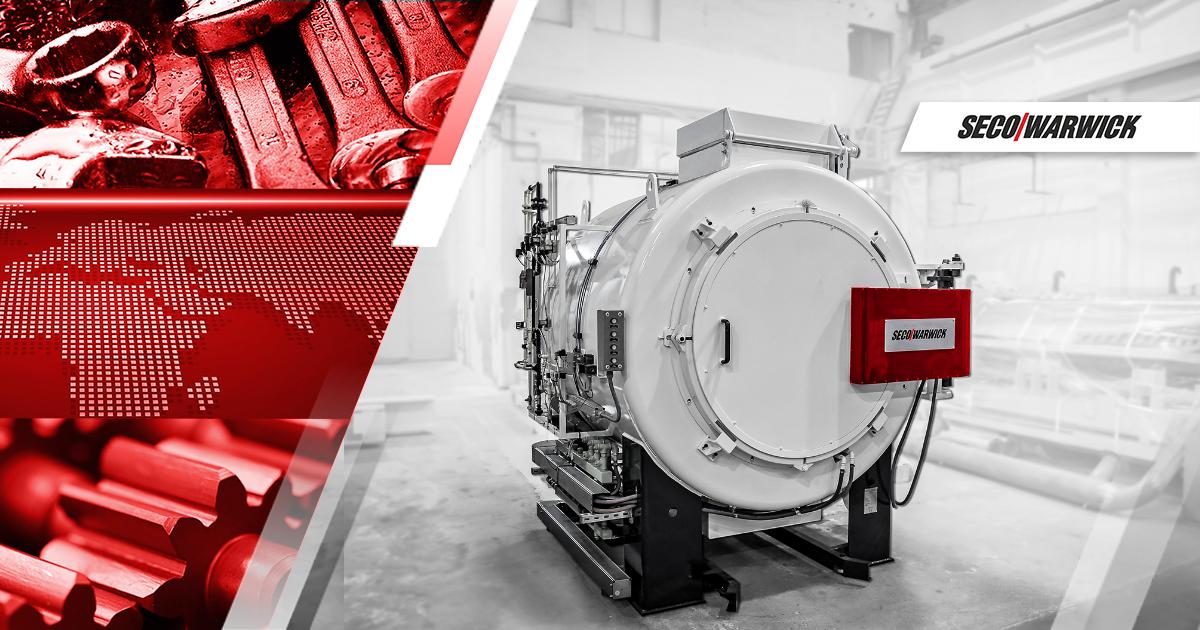

SECO/WARWICK will deliver their unique technology to another tool manufacturer. The company will deliver a retort furnace with vacuum purging for oxidation.

The retort furnace for the oxidation process operates under a nitrogen and hydrogen mix, then under steam, is the solution ordered from SECO/WARWICK. This latest furnace will be adjusted to the individual needs of the customer, providing the appropriate final hardness and their color of the workpieces. The solution will also enable tempering after vacuum purging. Contrary to appearances, oxidation is not a very common process on the market. It is used primarily in demanding industries such as automotive and aviation, however, the technology is increasingly widespread among tool manufacturers.

The retort furnace system designed to meet your needs

SECO/WARWICK’s contract for the delivery of the retort furnace continues the cooperation with this tool manufacturer, who currently operates a SECO/WARWICK vacuum furnace for brazing, hardening and vacuum carburizing. A new process solution, the retort furnace, will be designed according to the customer’s requirements, with a customized heating chamber so that the furnace is compatible with the tooling used in the customer’s production process, and so that the process itself is safe and repeatable. The characteristics of the manufacturing line and details of the production process are the key elements that will determine the final design of a dedicated solution.

“Innovations originate not only from the know-how of the SECO/WARWICK Group, but also from using the knowledge of our partners and listening to what they want to say. The needs of our customers provide the greatest momentum for individual solutions, constantly implemented by SECO/WARWICK. We are glad that we can deliver another furnace and increase the production capacity of our partner. Our goal is to become the first-choice supplier, and we are earning this title thanks to an individual approach, listening to the needs of our partners and innovations,” said Maciej Korecki, VP Vacuum Segment Business, SECO/WARWICK Group.

SECO/WARWICK specializes in ideal technologies for the tooling industry

According to the October 2020 Orbis Search report, the value of the global cutting tools market exceeded USD 36.8 billion in 2019. Market estimates indicate that, in the coming five years, the average annual growth rate of the global tooling industry will be approx. 2.4% p.a. As a result, in 2025, the value of the global cutting tools market will exceed USD 40 billion. ¹

¹ Source of the report: Orbis Search: https://nyheadline.com/press/global-machine-tools-market-and-cutting-tools-market-2020-demand-sales-production-supply-manufacturers-competitive-development-and-strategies-analysis-forecast-2025/27250

RELATED NEWS