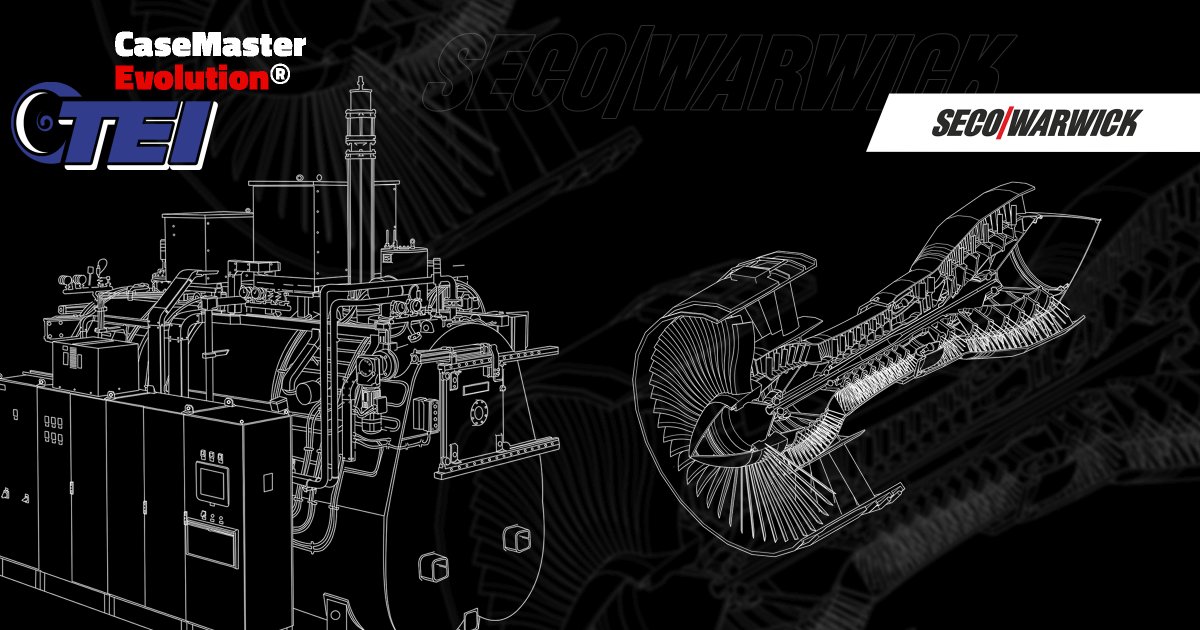

Given ongoing dynamic market developments, TEI – one of the largest Turkish manufacturers of aircraft engines – purchased a two-chamber CaseMaster Evolution® furnace from SECO/WARWICK, featuring a unique system for temperature measurement within the charge.

Turkey sees very dynamic growth in the aerospace and defense industries as a country. According to a Deloitte report,[i] the passenger traffic in Europe will grow by 5.2% until 2037, creating demand for 2,990 new aircraft worth USD 660 billion.

Aircraft engines require precision

The CaseMaster Evolution on order is a two-chamber vacuum furnace with an oil quenching system. The furnace offers a working dimension of 900x900x1200 mm and can process charges up to 1000 kg. The device will be equipped with a high vacuum system and a system for measuring temperature within the charge when heating and cooling. It will be used for the heat treatment of parts for aircraft engines.

“The equipment stands out, not only for its two-chamber design but primarily due to the critical improvement in the quality of the process, cost efficiency, increased performance, and better production flexibility. It is one of the most popular metal-treatment furnaces in the aerospace industry. This will be one of only a few multi-chamber vacuum furnaces worldwide fitted with a proprietary SECO/WARWICK system to measure temperature within the charge. Implementation of this innovation brings us superior heat treatment precision. This parameter is the most important one for the aerospace industry,” – said Maciej Korecki, VP, Vacuum Business Segment, SECO/WARWICK. “TEI is one of our long-term Turkish business partners. Although we have been cooperating for many years, this is the first delivery of a multi-chamber vacuum system for them,” – M. Korecki added.

TEI opts for SECO/WARWICK vacuum technology

So far, TEI has heat-treated components used to manufacture jet engines at commercial hardening plants that mostly use atmosphere furnaces. By selecting the CaseMaster Evolution (CMe-D) furnace, they will get better control over the quality, supply chain issues, and all the competitive advantages of vacuum technology.

“The technology proposed by SECO/WARWICK attracted our attention because of the high quality of treated components and process repeatability and environmental protection issues and better process efficiency. The two-chamber CaseMaster Evolution furnace will stand out on the Turkish market thanks to the very accurate charge temperature monitoring and superior quenchant temperature control. There are only a few devices of this kind worldwide. This brings us a great advantage and the ability to provide our hardening services to third parties,” – said Selcuk Kilicarslan, Special Process Manager from TEI.

Aerospace and defense – pillars of the Turkish economy

Turkey is an attractive market when it comes to the aerospace industry. According to the Deloitte report in the European market, wide-body aircraft comprise more than 40 percent of the total aircraft demand over the next two decades. This region offers mostly high-volume, ultra-long-haul flights.

When it comes to the defense industry, which is closely tied with aerospace, Turkey is one of the industry leaders. The Turkish military expenditure in 2018 was USD 19 billion, ranking 15 globally in terms of the value of their military budget. The turnover of the Turkish defense industry doubled in the last decade, reaching USD 8.8 billion. Along with the growth of the production capacity of the Turkish aerospace and defense sector in the previous decade, there was an increase in export and international cooperation opportunities for Turkish companies. The industry export sales grew from USD 600 million in 2007 to USD 2.2 billion in 2018. Thanks to the high production capacity, in 2018, the Turkish Industry won orders amounting to USD 12.2 billion[1].

[1] https://www2.deloitte.com/pl/pl/pages/press-releases/articles/obroty-przemyslu-lotniczego-i-obronnego-szybuja-w-gore.html

[i] The information about the Turkish Industry is from Deloitte Report and has been compiled by SECO/WARWICK

https://www2.deloitte.com/pl/pl/pages/press-releases/articles/obroty-przemyslu-lotniczego-i-obronnego-szybuja-w-gore.html