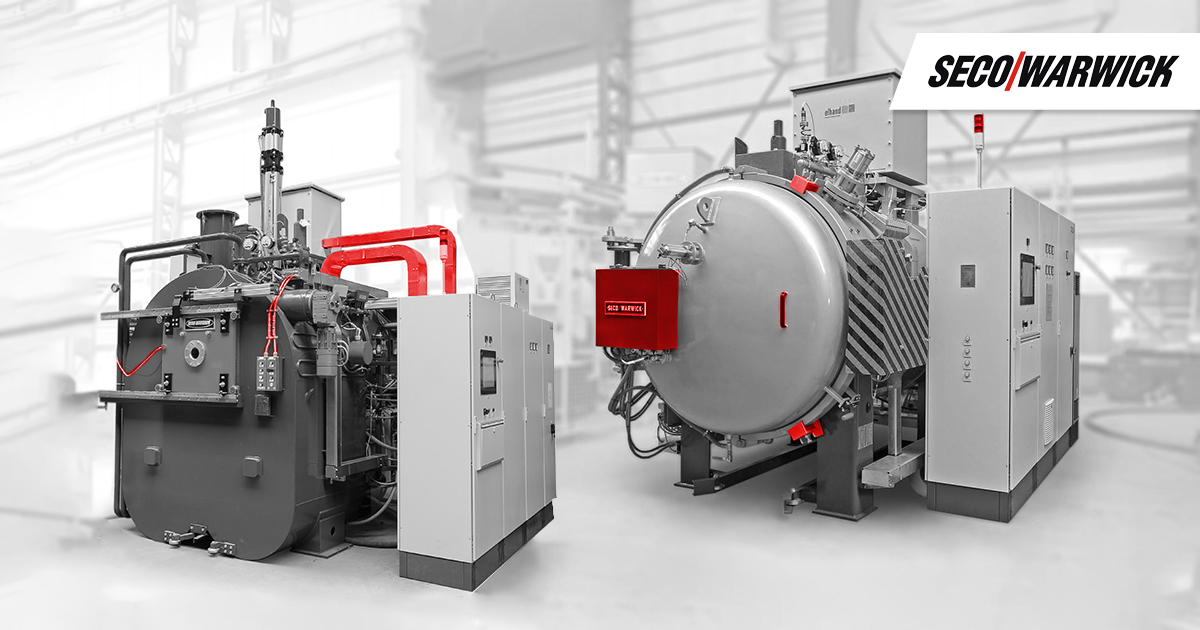

A top-tier Vector® vacuum furnace equipped with gas quenching from SECO/WARWICK will be used by a commercial heat treating plant. This time the Kuczma commercial heat treatment chose this state-of-the-art single-chamber vacuum furnace.

Vector is the most popular vacuum technology for heat treatment selected by commercial plants worldwide. This vacuum furnace is a very efficient and versatile system used for heat-treating many types of materials and metal alloys. Its functionality includes gas hardening and tempering, annealing, brazing and degassing. This Vector model — a vacuum furnace equipped with 1.5 bar gas quenching pressure — will significantly increase the capacity of the Kuczma Hardening Plant and will enable it to process parts with dimensions up to 600x600x900 mm.

This will be the first SECO/WARWICK furnace operated by the Kuczma Hardening Plant. Commercial heat treaters around the world, including Poland, select SECO/WARWICK technologies for many reasons, most importantly for their versatility, reliability and precision.

Vector — a perfect choice for commercial heat treaters

“The Vector technology is one of the two most sought-after solutions from SECO/WARWICK for heat treatment by hardening plants worldwide. CaseMaster Evolution (CMe) is a multi-chamber vacuum furnace with oil or gas quench. Both solutions share their process versatility and operating flexibility that distinguish the SECO/WARWICK solutions.” — said Maciej Korecki, Vice-President, Vacuum Business Segment, SECO/WARWICK.

For experienced family-run businesses such as the Kuczma Hardening Plant, one of many in Poland — selecting a SECO/WARWICK technology is a great market endorsement. But It is only one of the dozens in Europe and one of the hundreds around the world. Commercial heat treating plants are some of the most demanding industries since their needs are very broad and their equipment must be very adaptable to many processes.

“Kuczma Hardening Plant specializes mostly in vacuum quenching in gas, oil and gas nitriding of injection mould components and dies. The company has many years of experience and wishes to provide services of the highest quality with the shortest lead times possible. These are denominators we share with our technology partner, whom I have known personally ever since Elterma. Standards have neither changed for SECO/WARWICK nor for Kuczma Hardening Plant. We set the requirements high both for us and our selected technologies. Vector clearly meets them. On one hand, the SECO/WARWICK furnace will enable us to process larger components and increase our output for smaller ones on the other it will enable directional cooling sideways or top/bottom — said Jerzy Kuczma, Kuczma Hardening plant owner.

Tailor-made solution

The key features of the furnace for Kuczma commercial hardening plant include large working space in the furnace chamber — 600x600x900 mm — that accommodates items of larger dimensions, increases output and ensures versatility in processing a wide range of steels. A particular, tailor-made solution implemented in this furnace consists of the directional cooling which enables both quenching from sides as well as top and bottom.

The Vector furnace for this project features the unique sideways cooling that makes it possible to optimally adjust the gas cooling system to the batch configuration. Nowadays, customers from various industries expect increasing reliability, performance and better results of heat treatment. SECO/WARWICK Group’s Vector® vacuum furnace model responds to these expectations. A wide range of processes performed in single-chamber furnaces guarantees the highest heat treatment quality. This quality is guaranteed not only by state-of-the-art technology but also by the competent and experienced team of the customer.

Kuczma Hardening Plant

Kuczma Hardening Plant is a service company which was acquired from Zelnar sp. o. o. in 2013. Earlier, it was part of Zelmer tool shop. They specialize mostly in vacuum quenching in gas or oil and gas nitriding of injection mold components, dies and other items. The Hardening Plant also performs carburizing, quenching and tempering under a protective endothermic atmosphere as well as clean stress-relieving under nitrogen atmosphere. The Company has many years of experience and the necessary machinery to provide the highest-quality services with short lead times. Currently, the company is in the process of starting an induction hardening shop.