/Heat Treatment for the Power Industry

Heat Treatment for the Power Industry

Power applications

The power industry is the fourth key customer for SECO/WARWICK Group’s equipment. The power industry uses metalworking furnaces to manufacture dies, tools, heat exchangers, and pipes. Though gas turbines are a mature technology, there is always room for improvement. SECO/WARWICK’s solutions help to manufacture Plate & Bar heat exchangers, aluminum heat exchangers for air conditioning and the refrigeration industry, along with exchangers for condensing water vapor. We actively participate in projects related to renewable energy sources.

/ Vacuum furnaces for the power industry

PARTS: gas turbine parts, heat exchanger, tubes.

TECHNOLOGY: annealing, brazing, CVD

Vector High Vacuum Furnace

PARTS: alloyed steels, stainless steels, alloys and super alloys, titanium and titanium alloy

TECHNOLOGY: brazing, annealing, normalizing, homogenizing, stress relief, solution heat treating, aging, quenching, diffusion bonding, outgassing, sintering, tempering

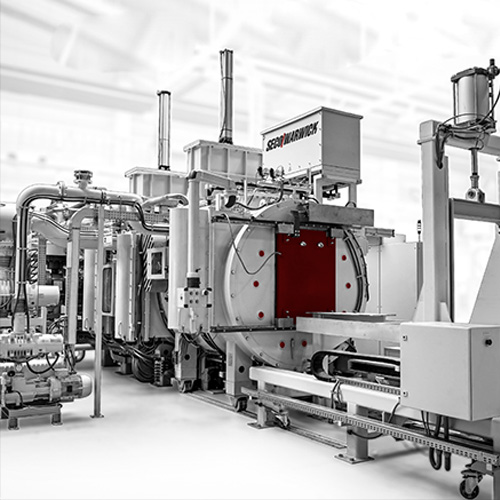

Triple chamber vacuum furnace for low pressure carburizing – CaseMaster Evolution® T

PARTS: heat exchanger

TECHNOLOGY: case hardening LPC, quenching, brazing, annealing

Integral Quench Furnace - Super IQ

PARTS: pumps, drilling equipment

TECHNOLOGY: vacuum carbururizing

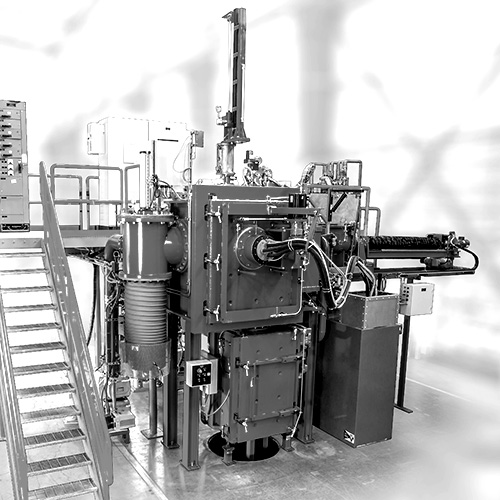

Vacuum system for single-piece nitrogen quenching - 4D QUENCH®

PARTS: higher alloy and special steels for gas and oil quenching

TECHNOLOGY: bright hardening (High Pressure Gas Quench)

The custom vacuum system for low pressure carburizing – UniCase Master® Custom

PARTS: higher alloy and special steels for gas and oil quenching

TECHNOLOGY: low pressure carburizing, bright hardening (High Pressure Gas Quench), bright annealing, vacuum brazing

/ CAB furnaces for the power industry

PARTS: dry condensing tubes, wind mills, electric power generators

TECHNOLOGY: contolled atmosphare brazing

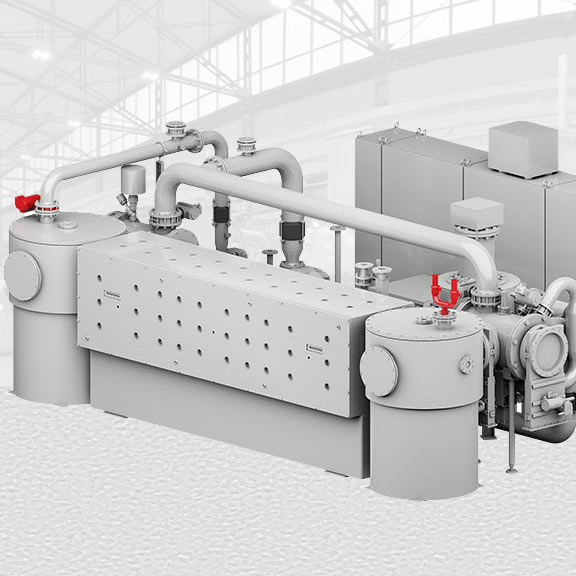

Continuous Brazing Furnaces for Aluminum EV/CAB

PARTS: dry condensing tubes, wind mills

TECHNOLOGY: contolled atmosphare brazing

Semi – Continuous Brazing Furnaces for Aluminum

PARTS: electric power generators -CACs

TECHNOLOGY: contolled atmosphare brazing

Universal CAB Batch

PARTS: electric power generators – radiators

TECHNOLOGY: controlled atmosphare brazing

/ Vacuum melting furnaces for the power industry

PARTS: gas turbine blades

TECHNOLOGY: equiax casting, directional solidification, single crystal casting

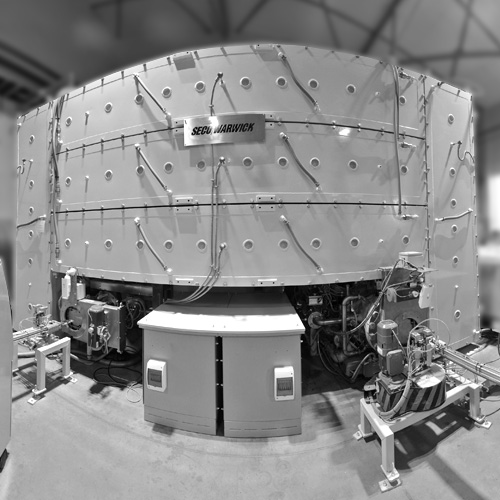

Vacuum Induction Melting (VIM)

PARTS: gas turbine blades

TECHNOLOGY: equiax casting, directional solidification, single crystal casting

/ Aluminum furnaces for the power industry

PARTS: wire, profile and foil

TECHNOLOGY: aging, annealing