HEAT TREATMENT FURNACES

SECO/WARWICK’s solutions for heat treatment of metals

At SECO/WARWICK, we approach each project individually – a client often looks for a solution that requires cooperation between different segments. We get to know the client’s needs, and together with experienced experts, we choose the best technology.

Industries: solutions for the automotive, aerospace, energy, medical, or defense industries. In a nutshell, for every industry. Specialists from SECO/WARWICK work together to find the right solutions for your company.

Unique features: energy-saving and environment-friendly equipment, access to new solutions and technologies defined by us, modern data control and analysis systems, and professional and professional services available in every part of the world.

Technologies: delivering the best results; as our partner, you have access to knowledge, experience, technology, and specialists in engineering and science, who are looking for other solutions.

Scope: standard and dedicated solutions, delivery of equipment with technology and associated devices, assembly and startup, service support, technical and technological training, tests and research in industrial and laboratory conditions, analyses, and simulations.

SECO/WARWICK solutions also include fire resistance tests furnaces, vacuum equipment, heat treatment equipment, chambers for precision tests, thermal processing systems, production lines for heating car windshields and their formation, and an individual solution prepared for your company, allowing you to gain an advantage over the competition.

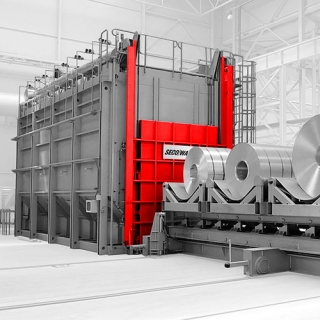

Aluminum Heat Treatment

Solution Heat Treatment, Artificial Aging, Annealing, Homogenizing, Aluminium Melting & Holding..

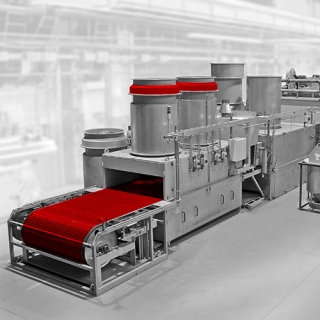

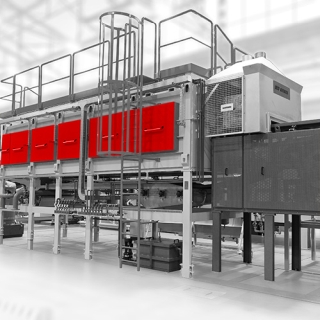

Thermal Heat Treatment Furnace Systems

Fire Resistance, Rotary Hearth, Rotary Retort, Roller Hearth, Pusher, Cast Link Conveyor, Mesh Belt, Walking Beam, Walking Hearth.

.

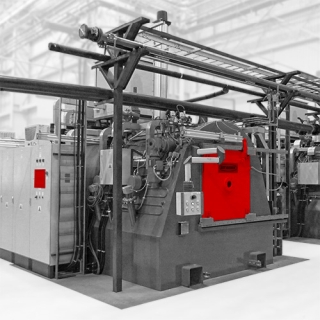

Technologies and equipment for vacuum heat treatment

Low Pressure Vacuum Carburizing, High Speed Vacuum Carburizing, High Pressure Gas Quench, Oil Quench, High Vacuum, Custom Engineered, Sealed Quench.

Vacuum Metallurgy

Vacuum Metallurgy (VIM, VAR, PAM, EB, PPE) for refractory metals, super-alloys and rare earth metals – casting, melting, refining, atomizing.

.

Used furnaces and heat treatment equipment

A second-hand industrial furnace is a great solution for those looking for a solution available immediately. It is also an opportunity for those who want to take advantage of an economic solution.

Automation services

It would be like a body without a brain and a nervous system. It is a mechanism full of opportunities, taking advantage of the potential of Industry 4.0, but only as a whole.

.